Reaktivni motori su fantastične mašine koje obavljaju važan posao čuvanja letova daleko iznad tla. Motori, kao što je prikazano na dijagramu turboventilatora od strane GE-a, jesu složeni sastavi s mnogim komponentama koje sve moraju raditi u skladu kako bi se ventilator okrećao upravo pravim brojem okretaja po minuti kako bi mogli voditi avion kroz zrak. Tlačna lisica je najznačajnija komponenta reaktivnog motora. U ovom članku promotrimo kako ove lisice rade i zašto igraju tako važnu ulogu u našim životima, te istraguju neke od načina na koje se tehnologija lisica vjetroparna razvija.

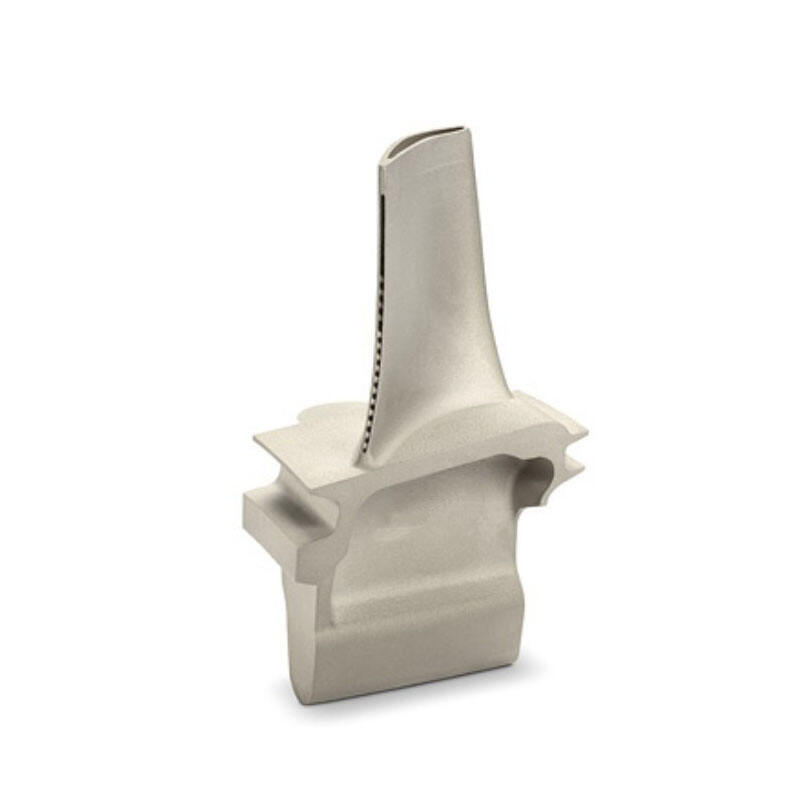

Zadatak šiljaka kompresora u jet motoru. Sijeku zrak s vanjske strane i stišavaju ga, čimajući taj zrak manjim i usižnjivšim prije nego što ulazi u drugi dio motora nazvan gorišni prostor. Veliki količina zraka se stišava u maleni prostor, a gorivo također dolazi... Oni se mešaju zajedno i prave veliku eksploziju koja pomaže motoru da radi. Budući da rade s toplinom i izdržavaju visoki tlak koji nastaje tijekom rada motora, ti šiljci moraju biti izvanredno jaci. Motor bi neispravno radio bez tih šiljaka, a avion ne bi mogao leteć.

Putem tehnoloških i inženjerskih napretka, lisice kompresora reaktivnog motora su se značajno razvile kroz godine. Tрадicionalno, ove lisice bile su jednostavne za proizvodnju zbog svoje osnovne metalne sastavnice. Ali kako je tehnologija postajala bolja, inženjeri su počeli razvijati nove lisice kompresora iz drugih materijala: keramike i posebnih plastika. Noovi dizajni omogućuju lisicama da izdrže više temperature i tlaka, a također su lakoje u težini od svojih metalnih prethodnika. Kao rezultat, savremeni reaktivni motori nisu samo efikasniji u trošku goriva, već i proizvode veću moć i nude letilima bržu vožnju na dužim udaljenostima.

Jedan ključni čimbenik za pružanje najboljeg izvedba od reaktivnih motora jest dovoljno održavanje njihovih kompresorskih lopatica. Lopatice, posebice kada su oštećene ili iznemogle, mogu imati izravan utjecaj na izvedbu, pa će redovne provjere (i inspekcije lopatica) osigurati da one nisu djelomično praskane što pomaže u zaštiti uloženja u vjetreniku. Lopatice se čiste sigurnom i pouzdanim postupkom umiva i prašenja, što štiti lopatice od obrazovanja ržave te ih čini sjajnim. Ponekad možda ćete također morati popraviti lopatice ili u mnogim slučajevima čak instalirati nove. S pravilno održavanim lopaticama, motor će funkcionirati na siguran način kako bi se izbjegle nesreće i osigurala je dugoročna funkcionalnost motora.

Izdvojene znanstvene načele leže iza funkcionalnosti šiljaka kompresora. Rotirajući šiljci djeluju poput kompresora, vučeći zrak s vanjskog okruženja unutra i tada ga stiskaju, što dovodi do zagrijavanja zraka zbog stiskanja. Čim je više stisnutog, toliko je i stisnuto! Ovaj stisnuti zrak se zatim miješa s gorivom i zapaljuje se, što uzrokuje moćan eksploziju koja gura motor dalje. Oblik i položaj šiljaka ima veliki utjecaj na koliko dobro šiljci stiskaju zrak. Kut šiljaka i njihova veličina moraju biti savršeno dizajnirani. To maksimizira snagu koja je potrebna da bi motor pravilno radio - stiskanjem zraka učinkovito.

Ključno je znati koje materijale se koriste za izradu šiljaka kompresora kako bi se odredilo koliko dobro funkcioniraju u reaktivnom motoru. Među šiljkama, metal je najtrajaniji (u usporedbi s plastikom ili stakлом). Oni koji su napravljeni od nerđavećeg čelika neće se iškrivljavati tijekom vremena zbog topline. S druge strane, keramički šiljac je lagan i manje porozan za toplinu - međutim, hrupeći je i osjetljiviji na oštećenja. Zbog svoje mase, jačine i sposobnosti da izdrže toplinu i tlak, složeni šiljac je odličan izbor za inženjere. Stoga, pri projektiranju i odabiru šiljaka kompresora, inženjeri moraju uzeti u obzir prednosti i nedostatke svakog materijala kako ne bi kompromitirali performanse motora.

Držimo se kompresorskih lopatica mlaznog motora za kontrolu kvalitete kako bismo garantirali performanse i pouzdanost svake komponente. Kontrola kvalitete provodi se tijekom cijelog proizvodnog procesa, od kupnje sirovina do ispitivanja gotovog proizvoda. Kako bismo osigurali da se kvalitet našeg proizvoda stalno poboljšava, mi također redovito provodimo revizije i poboljšavanja. Naš cilj je osvojiti povjerenje i suradnju naših klijenata nudeći vrhunske proizvode i postati lider u industriji.

Naša podrška klijentima je kompresorska lopata mlaznog motora i uključuje tehničku pomoć, pre-prodajno savjetovanje i pomoć nakon prodaje kako bi se osiguralo da naši kupci imaju najbolje moguće iskustvo. Naš iskusni tim će pregledati potrebe kupaca i ponuditi najefikasnije rješenje i preporuke za proizvod. Pružamo tehničku podršku od izbora proizvoda do ugradnje i puštanja u rad. To jamči da naši klijenti mogu uživati u našim proizvodima bez problema. Imamo dobro razvijenu uslugu nakon prodaje koja nam omogućuje da brzo reagiramo na zahtjeve i probleme kupaca i pružamo brza i pravovremena rješenja. Nastojimo uspostaviti dugoročne odnose s našim kupcima i zaslužiti njihovo povjerenje i poštovanje pružajući kvalitetnu uslugu.

Naša tvrtka nudi različite usluge prilagođene, i proizvodi komponente turbina iz niza visokotemperaturnih kompresornih lopata mlaznog motora kako bi zadovoljili zahtjeve naših kupaca. Naš fleksibilan proizvodni proces i napredna tehnologija za obradu i naša sposobnost da zadovolji određene zahtjeve, kao što su veličina, oblik, performanse ili oblik, omogućavaju nam da ostvarimo svaku potrebu. U bliskoj smo komunikaciji s našim klijentima kako bismo u potpunosti razumjeli njihove individualne zahtjeve i situacije te im pružali stručna savjeta i rješenja. Nudimo širok spektar materijala i mogućnosti obrade kako bismo zadovoljili specifične zahtjeve različitih industrija i primjena. Kroz prilagođene usluge pomažemo našim kupcima da optimiziraju performanse i učinkovitost proizvoda i povećaju konkurentnost na tržištu.

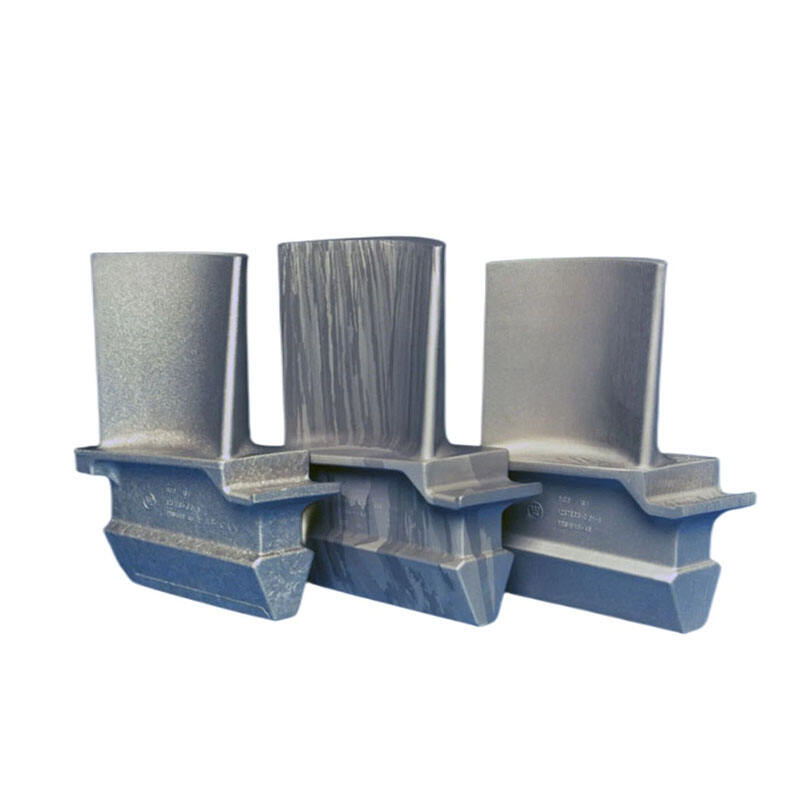

Možemo proizvoditi komponente turbina s visokom točkinjom i dosljednim kvalitetom kroz CNC obradu, odlijevanje i kovanje. Odlivom možemo stvoriti dijelove složenih oblika, visoke čvrstoće i dugotrajnosti. Kovanje može dijelovima dati izdržljivije i superiornije mehaničke osobine. S druge strane, tehnologija CNC kompresorskih lopatica mlaznog motora osigurava najvišu preciznost i točnost svakog dijela, minimizirajući pogreške i osiguravajući da je proizvod visokog standarda. Naš visoko kvalificirani tehnički tim neprestano razvija tehnološki napredak i optimizaciju procesa kako bi naši proizvodi bili na vrhuncu tehnologije u industriji. Naša je obveza da zadovolji potrebe naših kupaca za komponentama koje su visoke performanse kroz kontinuirani razvoj tehnologije.