Have you ever wondered which type of engines are used in airplanes, rockets and cars? It's pretty interesting! The process of casting superalloy is one important method for this engine manufacturing. It is important during this design optimization stage Superalloy Casting Among the special kind of materials we called superalloys, solved in one of its processes for manufacture powerful and durable parts to machines. This is the combination of skill and science to make sure that these components are constructed correctly for their purpose.

I mean here with super alloys is nothing but the special kind of materials. They are also able to withstand very high temps, pressure and stress w/o breaking or getting damaged. So it is perfect for manufacturing parts, which have to perform well under tough and extreme working conditions. In this manner parts which are in motors, those specific things go through heat and Stress so that must be very strong. Okay ok a lot of grunt. but to create these parts, man! The casting of superalloy is a blend information, skill and technology effort. Now all the bigger hallmark that everyone working with superalloys needs to know is how long an airframe will last at these levels.

Precision casting is also a very important step in the process of superalloy atmospheric pouring. This means that the superalloys are used in definite forms and sizes to make them suitable for different kinds of equipment. Verify: This is a critical step in which we check if all parts fit together as expected. If a part is made incorrectly, it may not work for its intended purpose in the engine or machine. It is a method of making products, including investment casting, sand casting and die-casting. At the end of it all, just as there is no best process for each application; one method always has its benefits than another and that's why you determine the correct proces by knowing which partiular part are required.

Consequently, superalloy casting is essential to the production of most long service life components used in many industries such as aerospace and defense. These industries rely on these superalloy parts for their machines and engines to operate at higher speeds while being more efficient in hot environments. These engines require powerful components to function properly. Superalloy parts for medicine, and other industries like oil&gas or automotive. Every one of these areas needs components that just work and, most importantly — safely.

Superalloy Casting is key for the aerospace and defense inustires Some of Generally critical Alloys from super alloys made as, egPlane engines & Rocket Engines + many parts which subject to High temperatures. For example, an airplane is required to have its part as strong at the same time they should not add up that much weight because then carrying itself would have been a problem. These must also be able to hold up against the extreme temperatures that are formed in flight. Similarly, one in every of defense products (e.g., military systems) demands parts are needed from superalloys with sufficient mechanical properties to not split up underneath the regular use conditions.

Today, the most advanced methods and technologies are used to create a top-notch superalloy components. Its also demand those old skilled Technicians and engineers to design for fab, fabricationand validation of parts. Quality parts with accentuated testing are paramount as well. This allows the parts to be high performing and meet safety regulations while operating in machines, engines etc.

Our comprehensive customer service includes pre-sales consulting technical support and after-sales services to ensure that customers enjoy the most enjoyable experience Our expert team will assess the needs of customers and offer appropriate product suggestions and solutions We provide technical support starting with the selection of products through installation and commissioning This ensures that our customers are able to enjoy our products without issues For after-sales support we have developed an efficient service system that can respond swiftly to customer issues as well as needs and provide superalloy casting and efficient solutions Our goal is to create long-term relationships and gain customers trust and their satisfaction by providing superior customer service

We follow superalloy casting for quality control to ensure the performance and reliability of every component. The entire process of production is subject to quality control, from the raw material purchase until the final testing of the product. We also regularly conduct quality audits and improvements to ensure continuous improvement of product quality. We are determined to gain the trust of our clients and to maintain their long-term relationship by offering high-quality products.

Our company can provide customized services and is able to fabricate turbine components from an array of high-temperature alloys in accordance with the requirements of customers. No matter what superalloy casting, size or performance requirement, we can achieve it with our flexible production process and cutting-edge technology for process. We work closely with clients to comprehend their needs as well as the various scenarios they might encounter and give them professional assistance and suggestions. We have a variety of materials and processing capabilities to meet the unique requirements of different industries and applications. We aid our clients in improving their competitiveness on the market by offering custom-designed services that improve efficiency and lower costs.

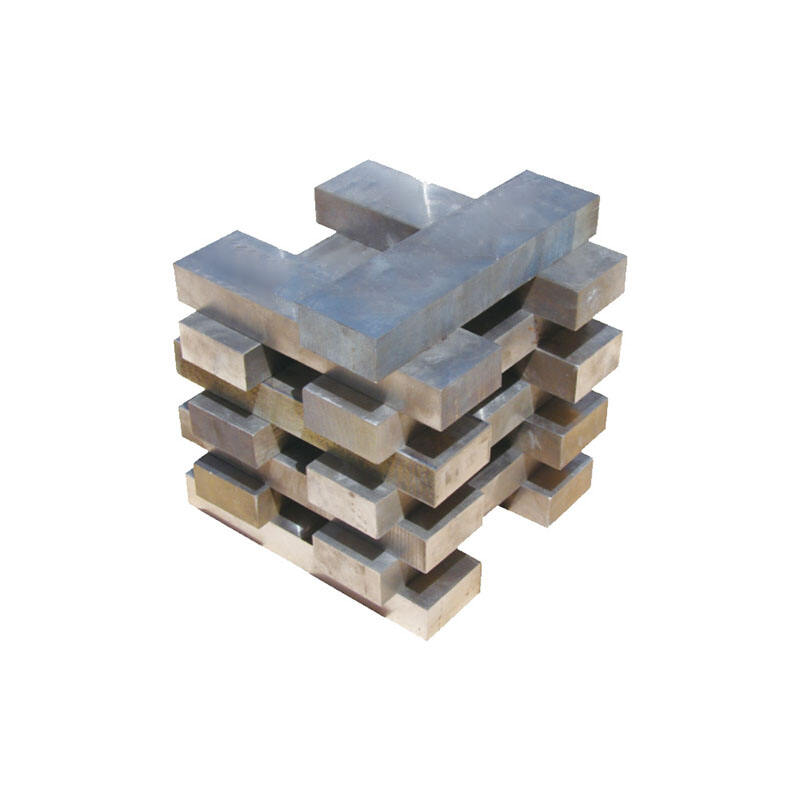

Our company has the ability to create highly precise and reliable turbine parts through casting superalloy casting, and CNC machining processes. Casting allows us create components with complex designs, strong and long-lasting. Forging provides parts with a better mechanical quality and longer durability. CNC machining, on the contrary offers high precision and consistency for every component. This reduces errors and inferior products. Our technical staff is constantly developing technological advancements and process improvements to ensure our products are at the forefront of industry technology. We're committed to meeting our customers' demands for high-performance turbine components by continual technological advancement.