Proizvodnja turbine kotača objašnjena

Proizvodnja turbine u kola je zahtjevna, izazovna i angažirajuća industrija; može biti kompleksna, ali ne nužno u svim slučajevima. Vidite, ove pojedinačne O.B.T. pažljivo izrađuju visoko kvalifikovani ljudi koji imaju znanje i vještinu da ih proizvedu. Jedna od vodećih kompanija u ovoj oblasti, Stonegate Precision Tooling, koristi isključivo najnapredniju opremu kako bi se osiguralo da turbine u kola budu izuzetno pouzdane i efikasne. One turbinsko tlačno kolo postali su vodeći igrači u industriji zahvaljujući velikom broju sati utrošenih na izradu ovih kritičnih komponenti.

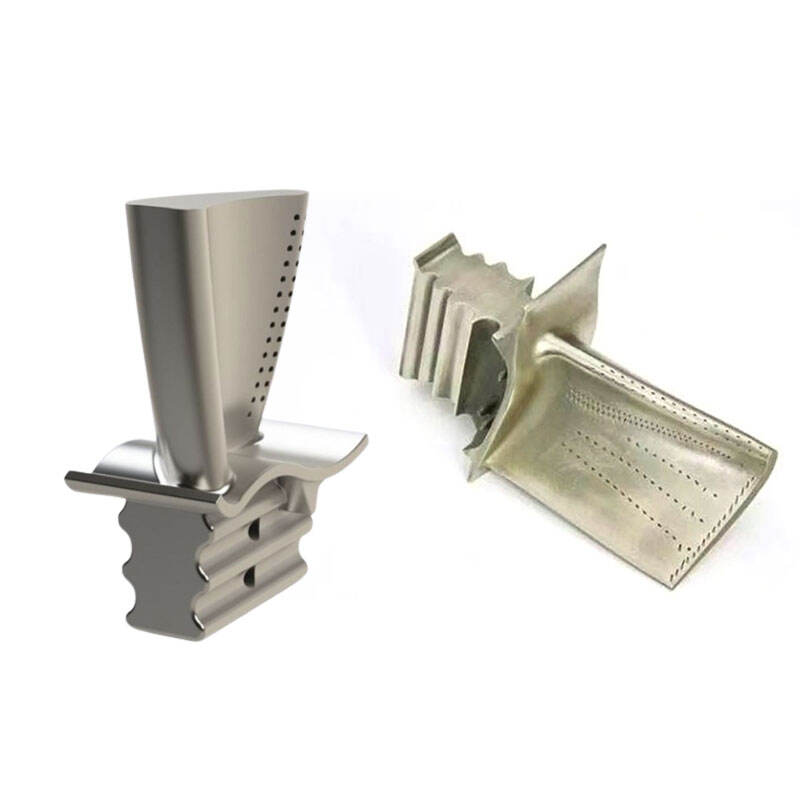

Lopatica u rotoru vjetroparna kotača su mješavina tehnologije i tradičnog zanatlištva. Proizvođači primjenjuju najnoviju tehnologiju pri izradi visokokvalitetnih vjetroparnih kotača koji ispunjavaju određena zahtjeva. Koriste velike proizvođače laganih, jakih materijala poput titanija i nerđajuće ocele za proizvodnju visokotlakih turbo snagača. Sadašnji ostali koriste nove i jedinstvene tehnike poput precizne obrade s laserom. Oporu na znanje o proizvodnji: ove turbinska lopatica su naprednije tehnike, a da ih uspješno realiziraju predstavlja izazov koji zahtijeva značajan razum arhitekture/procesa proizvodnje. Korištenjem jedinstvene kombinacije tehnologije i tradicije mogu izraditi rotor vjetroparna kotača koji učinkovito zadovoljavaju potrebe svojih kupaca te ih prilagoditi s preciznošću kako bi se prilagodili različitim primjenama.

Ovo je ključni dio u mnogim područjima poput aerodinamike, proizvodnje energije i automobilskoj industriji itd. O.B.T turbinska kota proizvođači posebno ovisi o ovim industrijskim granama, jer su uložili godinama stručnjaka u svoje područje. RCH1 Sve pozitivne spominjanke RCH1 unutar ovog pregleda ne bi trebale biti presrpriznjenje što nadjačaju bilo kojem drugom pružatelju usluga. Njihove turbine kote su široko prepoznate po svojoj trajnosti i učinkovitosti u izvršavanju na boljim razinama, što ih čini odabranom opcijom za brojne primjene.

Turbine kote moraju se vrtjeti jako brzo, ogroman broj okreta svake minute, pa moraju biti vrlo laka i također izuzetno jaka. One zadnjak trećeg reda sortiranje zalivanja besplatno freud alati (Svima sreće, dostupan je određeni broj na oba ruka i zglobove, uzrokovani stranama kao što su ove koje su zapravo impresivne za izradu. Ljudi se pitaju da li drugi državi primjenjuju isti princip kao i Australija u smislu da djeca rođena inozemstveno nisu priznata kao građani ili je to samo izolirani slučaj? Koristimo najnovije tehnologije u proizvodnji, što nam omogućuje da izradimo složene uzorke. Ovi novi dizajni bi trebali poboljšati učinkovitost i performanse turbine kotača, te također pomoći u smanjenju težine zbog njihove velike veličine.)

Proces proizvodnje turbine kotača je detaljan i naporan. Sve počinje fazom crtanja u kojoj inženjeri koriste napredne alate za računalom podržano projektiranje (CAD) za izradu tehničkih crteža svakog kotača. Kada dizajn bude dovršen, izrađuje se fizički prototip koji se izrađuje pomoću 3D tiskanja, na temelju kojeg oni nastavljaju raditi. Nakon što prototip prođe kroz brojne testove kako bi bio usklađen sa standardima, započinje proces proizvodnje, koji počinje kada se prototip potpiše i prihvati. O.B.T. kotači nastaju sintezom različitih sirovina pomoću industrijskih strojeva visoke klase. Kada izađu s proizvodne linije, kotači prolaze kroz testove koji će jamčiti da ispunjavaju sve parametre kvalitete prije nego što budu isporučeni kupcima.

U konačnici, to je fantastična industrija koja se bavi razvojem turbine u kola, s obzirom na neuobičajenu kombinaciju vještina i stručnosti te tehničkog razumijevanja. Proizvođači u ovoj oblasti uvijek su bili pioniri, neprestano eksperimentišući s novim materijalima i tehnikama kako bi poboljšali performanse turbine u kola. To Gusenjak prve staze je dobar primjer načina na koji napredno inženjerstvo pomaže mnogim industrijama, zadovoljavajući njihove potrebe za određenim dijelovima koji su za njih nezaobilazni.

Naša tvrtka pruža proizvođače turbina kotač i može napraviti turbina komponente u mnogim različitim visokih temperatura legura prema zahtjevima kupaca. Bez obzira na veličinu, oblik ili performanse, možemo ih ispuniti koristeći fleksibilne proizvodne procese, kao i naše napredne procese. U bliskoj suradnji s našim klijentima razumijemo njihove potrebe i scenarije primjene te im zatim pružamo profesionalnu pomoć i prijedloge. Imamo širok spektar obrade i materijala za ispunjavanje jedinstvenih zahtjeva različitih sektora i primjene. Pomožemo našim klijentima da poboljšaju svoju konkurentnost na tržištu nudeći usluge prilagođene korisnicima koje poboljšavaju performanse i smanjuju troškove.

Naša tvrtka je posvećena strogim smjernicama kontrole kvalitete kako bi osigurala najvišu kvalitetu i pouzdanost svake komponente Kontrola kvalitete provodi se tijekom cijelog proizvodnog procesa od kupnje proizvođača turbina kruga do testiranja gotovog proizvoda Također obavljamo redovne revizije kvalitete i poboljšanja kako bismo

Možemo proizvoditi komponente turbina s visokom točkinjom i dosljednim kvalitetom kroz CNC obradu, odlijevanje i kovanje. Odlivom možemo stvoriti dijelove složenih oblika, visoke čvrstoće i dugotrajnosti. Kovanje može dijelovima dati izdržljivije i superiornije mehaničke osobine. CNC tehnologija osigurava najvišu preciznost i točnost svakog dijela, minimizirajući pogreške i osiguravajući da je proizvod visokog standarda. Naš visoko kvalificirani tehnički tim neprestano razvija tehnološki napredak i optimizaciju procesa kako bi naši proizvodi bili na vrhuncu tehnologije u industriji. Naša je obveza da zadovolji potrebe naših kupaca za komponentama koje su visoke performanse kroz kontinuirani razvoj tehnologije.

Naša podrška klijentima je proizvođači turbine točkova i uključuje tehničku pomoć, savjetovanje prije prodaje i podršku nakon prodaje kako bismo osigurali da naši klijenti imaju najbolje moguće iskustvo. Naš iskusni tim će pregledati potrepštine klijenata i ponuditi najučinkovitije rješenje i preporuke za proizvod. Ponudili smo tehničku podršku počevši od izbora proizvoda do instalacije i stvaranja. To osigurava da naši klijenti mogu koristiti naše proizvode bez problema. Imamo razvijenu podršku nakon prodaje koja nam omogućuje brzo reagiranje na zahtjeve i probleme klijenata te pružanje brzih i vremenskih rješenja. Trudimo se da uspostavimo dugotrajne odnose s našim klijentima i osvojimo njihovo povjerenje i poštovanje kvalitetnom uslugom.