HPT disks are among the most critical things in a jet engine and are key to getting aeroplanes up into the sky. They are engineered to thrive in the extreme pressure and heat of an engine, thus also deliver optimal performance.

Every high-pressure turbine disk, however, is designed and fabricated using a complex series of steps. Constructed out of high heat and ultra-high speed materials, the discs are able to handle anything you can throw at them. Additionally, the disks incorporate custom designs to suit each specific jet engine itswill function in and account for parameters such as engine dimensions, power output and temperature range.

When the design phase is over, manufacturing begins. Every high-pressure turbine disk is machined and polished, followed by heat treatment to ensure the final product meets specifications for safe operation.

For modern jet engine technology high pressure turbine disks are crucial to lead the air accelerated by combustion and this propulsive force is enough to let aircraft fly through, because it works closely with compressor that mixes fuel with compressed fresh air. Jet engines would not be able to produce the power necessary to get heavy jets airborne without these disks. So the development of high-pressure turbine disks has been key to the advancement in Jet Engine technology.

Despite being intricately engineered and manufactured, high-pressure turbine disks are subject to stress over time which can lead to fatigue, eventually causing failures. To counteract this threat, engineers run complex tests to analyse the stress and fatigue in the disks that they would endure during ordinary flight. Through analysis of the data obtained by these tests, engineers may be able to identify and address any potential design weaknesses in the disks before they become an issue that risks putting lives at danger resulting from disk failures during engine operation.

Efficiency of jet engines is a never ending issue in aviation industry with high costs and environment reasons. One way to do that is by improving performance of high-pressure turbine disks. This means new method and materials will be developed to lighten the weight of the disks, while at same time ensuring their strength and longevity (durability). Jet fuels burn very efficiently and tend to be low in sulphur, thanks at part (although by no means wholly) to these advances.

In summary, high-pressure turbine disks are key elements for current jet engines and engineers always try to improve their properties of strength, reliability and efficiency. Competition looms, but high-pressure turbine disks will continue to play a major role in jet engine design for the foreseeable future through continued advancements and improvements that keep air travel as safe and efficient as possible.

Our company adheres to strict quality standards to ensure the highest quality and the reliability of every component Quality control is carried out throughout the entire process of production from the acquisition of raw materials to the testing of the final product We also perform regular quality high-pressure turbine disk and adjustments to ensure constant improvements in product quality Our goal is to win the trust and long-term cooperation of our clients by offering high-quality products and to become a leader in the industry

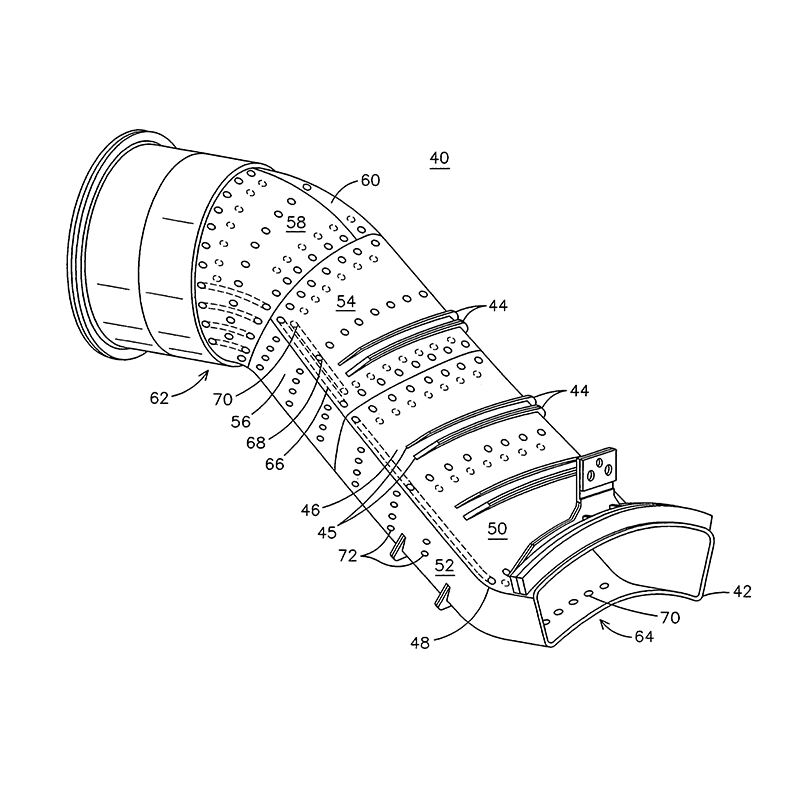

We are able to create turbine components with high accuracy and consistency using CNC casting, machining and forging processes. Casting allows us create parts with high-pressure turbine disk, strong and durability. Forging offers parts more durable and superior mechanical property. CNC machining, on the contrary is extremely precise and consistency for each part. This eliminates mistakes and poor quality products. Our experienced technical team is continuously researching technological advances and process optimizations in order to keep our products at the leading edge of industry technology. We're committed to meeting the demands of our customers for high-performance turbine components by the continuous advancement of technology.

Our customer support is high-pressure turbine disk and includes technical assistance, pre-sales advice and after-sales assistance to ensure our customers have the best possible experience. Our experienced team will review the needs of customers and offer the most effective solution and recommendations for the product. We provide technical support starting with the selection of products to installation and commissioning. This guarantees that our clients are able to enjoy our products without problems. We have a well-developed after-sales service that allows us to react quickly to customer requests and problems and provide quick and timely solutions. We strive to establish long-term relationships with our customers and earn their trust and respect by providing quality service.

Our company provides high-pressure turbine disk and can make turbine components in many different high temperature alloys according to the requirements of customers. Whatever the size, shape, or performance requirement, we are able to meet it using our flexible production processes as well as our advanced processes. We collaborate closely with our customers to comprehend their needs and applications scenarios and then give them professional assistance and suggestions. We have a broad range of processing and materials to meet the unique requirements of different sectors and application. We help our clients improve their competitiveness in the marketplace by offering custom-designed services that improve performance and reduce costs.