Gas Turbine is a unique device which converts gases into energy. It burns gas in a specialized chamber, which makes lots of heat. The heat causes the blades in the turbine to spin fast and that spinning can create electricity we use every day. But there is a twist to this process. The gas exits the turbine at high velocity and is also very hot. This is where the gas exits extremely hot and at high speed - a condition that we have to somehow manage with what's known as a gas turbine exhaust diffuser. A diffuser is essentially a giant funnel. Simply put, its purpose is to reduce the speed of the hot gas so that it becomes more manageable. It also allows the gas to be dispersed and vent smoothly into the atmosphere, which is critical for our ecosystem.

The creation of a gas turbine exhaust diffusers requires significant engineering. The size and shape of the diffuser are crucial. It has to be large enough that the gas can slow down in it, but not so big as to closure problems with pressure. The gas can also slow down suddenly causing a pressure loss which the turbine has repressurize, thus burdening work. This additional effort can cost more gas which is expensive. Also, the material that is used to make diffuser has to be strong. Because if it does, this thing wont work right…ressive! It must be abrasion resistant and last beyond very high temperature.

An exhaust diffuser in a well design gas turbine can greatly save energy. This is critical because it would not be appropriate to subject the gas, flowing out of the turbine at a certain velocity so as not have to brake oneself. It is less costly if the gas slows down gradually, then energy will be saved. If the diffuser is too restrictive, it will cause higher pressure drop across the turbine causing more gas to be needed. The diffuser can also lead to a loss of pressure should it be oversized. This is exactly why one must choose the diffuser size wisely. The shape of the diffuser also has another significant impact: it determines how gas flows out of turbine. By building a diffuser well, the gas will be able to fly past much better and smoother.

The gas turbine exhaust diffuser must be well maintained to guarantee that it will work fine. However, if the diffuser is damaged prematurely or dirty due to communication problems turbines. So, it is essential that you frequently inspect the diffuser to know if everything goes on well. If there is a problem, which should be fixed early to avoid potential new ones. The type of material and finish on the diffuser is also a critical point. It must be heat-resistant and should last you a good while. Like all aspects of your turbine, if the diffuser is seeing a lot of wear and tear then it must be replaced in order to ensure that you are able to keep operating efficiently.

A well-designed gas turbine exhaust diffuser leads to a noticeable improvement of the efficiency possibles for the operation mode of a stand-alone (gas) turbine. The better the diffuser, the more efficiently gas fills everything up in a volume to be burnt and produce power. This is a win-win of saving energy and keeps costs down. Moreover, a good diffuser can reduce pressure losses-which is always welcome efficiency-wise. In addition, the manufacturing materials of a diffuser is also very essential. They have to be tough and able to withstand harsh conditions yet still remain operational over a long period of time. On this regard, as soon the diffuser is worn out it has to be replaced preventing and damage in performance of turbine.

Our customer support is comprehensive and includes technical assistance, gas turbine exhaust diffuser and after-sales assistance to ensure that our customers get the best possible experience. Our team of experts will evaluate the requirements of the customer and offer appropriate product solutions and suggestions. We provide technical support throughout the entire process, from choosing products, to the installation and commissioning. This guarantees that our customers can make use of our products with no issues. We have developed an after-sales service that allows us to quickly respond to customer requests and problems and provide efficient and timely solutions. Our goal is to establish lasting relationships with our customers and gain their confidence and satisfaction with quality customer service.

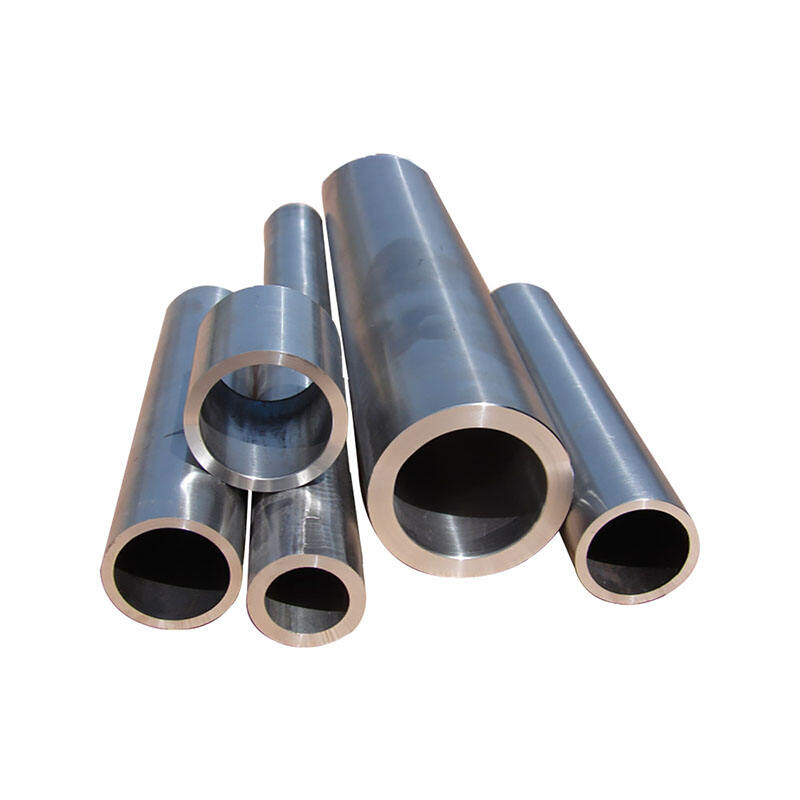

Our company can provide customized services and is able to fabricate turbine components from an array of high-temperature alloys in accordance with the requirements of customers. No matter what gas turbine exhaust diffuser, size or performance requirement, we can achieve it with our flexible production process and cutting-edge technology for process. We work closely with clients to comprehend their needs as well as the various scenarios they might encounter and give them professional assistance and suggestions. We have a variety of materials and processing capabilities to meet the unique requirements of different industries and applications. We aid our clients in improving their competitiveness on the market by offering custom-designed services that improve efficiency and lower costs.

Our company is committed to strict quality control guidelines to ensure the highest quality and reliability of every component Quality control is conducted throughout the entire manufacturing process from the purchase of gas turbine exhaust diffuser to the test of the finished product We also perform regular quality audits and improvements to ensure continuous improvement in the quality of our products Our aim is to earn the trust and long-term cooperation of our clients by offering quality products that are of the highest standard and to be a leader in the industry

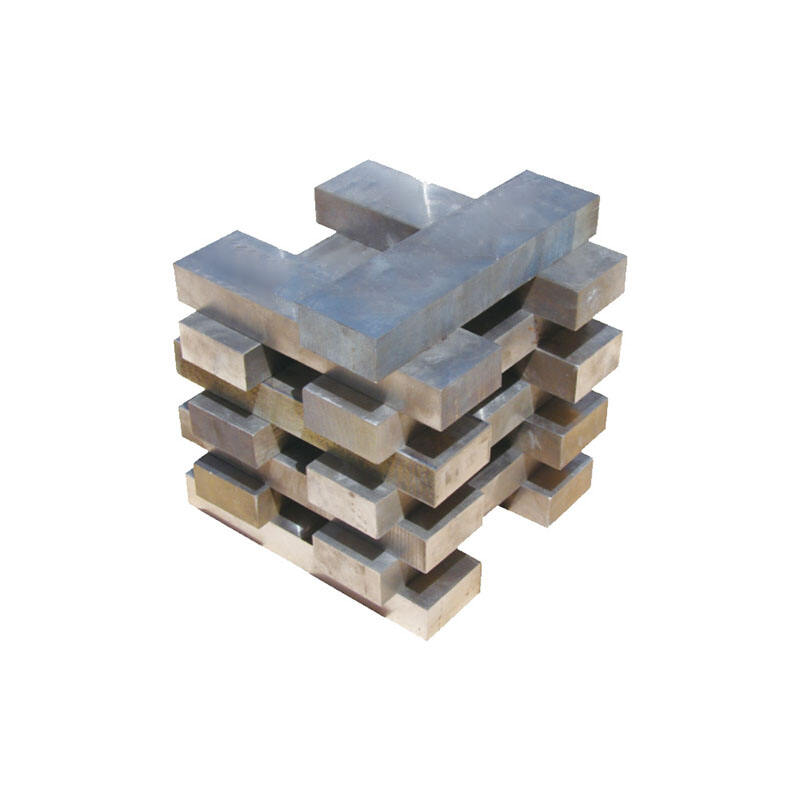

Our company can fabricate highly precise and stable turbine parts through casting forging, and CNC machining. Casting allows us to create components with complex forms, high strength and long-lasting. Forging can give parts a more durable and superior mechanical property. CNC technology for machining, on other hand, ensures high precision and consistency of every part, which reduces the chance of the chance of errors and producing substandard products. Our technical team that constantly carries the latest technological advancements and process improvement to make sure that our products are always at the top of the industry in terms of gas turbine exhaust diffuser. We're determined to meet our customers' demands for high-performance turbine components through continuous technological advancement.