When it comes to the casing of steam turbine, O.B.T is a brand you can really rely on! We are a professional producer for high-quality casings which are made to customers' needs. We offer various choices from the smallest casing to large casing sizes. Whether it be power generation, oil and gas or marine, we have your casing. Our designs are outfitted under stringent quality and design standards, contributing to high-grade durability and prolonged life expectancy.

Locating the best steam turbine casing suppliers can be challenging, yet from O.B.T you know what top of the line quality is. Quality and satisfaction are guaranteed with our company. We pay attention to our customer’s needs and works around the clock to meet customers expectations. Having been in the business for several decades, we can say that our products are synonymous with quality and precision. We have the latest machinery and technology within our facility to make sure every casing is of high quality.

It is critical to select the appropriate steam turbine casing for your requirement in order to meet performance and efficiency targets. O.B.T has multiple casing types to fit your needs and more. From small warehouse to major high rise plant we have the solution you are looking for! Our knowledgeable team can direct you through choosing the ideal part for your crusher. based on your specific needs We have a wide variety of high quality parts in stock at our location, as well as computer design technology to ensure precision and customized jaw parts! We specialize in hands-on personal service that gives the bride and groom precisely what they need for their special day. With O.B.T, you can not go wrong in obtaining the right steam turbine casing for your application.

Steam turbine casing is one of the major component in power plants and it often encounters few common problems which may affect its performance. One of the challenges is corrosion, which can be caused by the high temperatures and pressures inside the turbine. Such a problem can be solved by employing good materials which possess an anti-corrosion characteristic, such as stainless or titanium. Routine maintenance and inspection may also prevent corrosion and extend the life of the casing.

A second problem area is vibration, which can cause the casing and other parts of a turbine to be damaged. The only way to fix this issue is to make sure the housing (casing) is installed/aligned correctly. Clients can use these to installed Vibration Monitoring systems for early detection of performance issues and damage avoidance.

When you purchase steam turbine casing components in large volumes, there are some things you need to know to make sure yo ureciving a good product. One of the key concerns is the material used for the casing, which has to bear high temperatures and pressures. Attention is to be given as well to the design and the construction of the casing and to additional features, e.g., insulations or coatings.

Furthermore, steam turbine casing may comply with reducing heat dissipation from the turbine thus contributing to a more energy efficient device. Thermal resistance can be increased by insulating the shell or employing material of high thermal resistance, thereby reducing the loss of heat and promoting power generation efficiency.

Our company provides steam turbine casing, and we is able to manufacture turbine parts from many high-temperature aluminum alloys in order to satisfy the demands of customers. Our flexible production flow and advanced technology for processing and our ability to satisfy particular requirements, like size and shape, as well as performance will allow us to meet any need. We work closely with customers to fully comprehend their requirements and applications scenarios and provide them with expert assistance and suggestions. We have a broad range of materials and processing capabilities to meet the special demands of various industries and applications. Our clients can improve their competitiveness on the market by offering customized services that optimize performance and reduce cost.

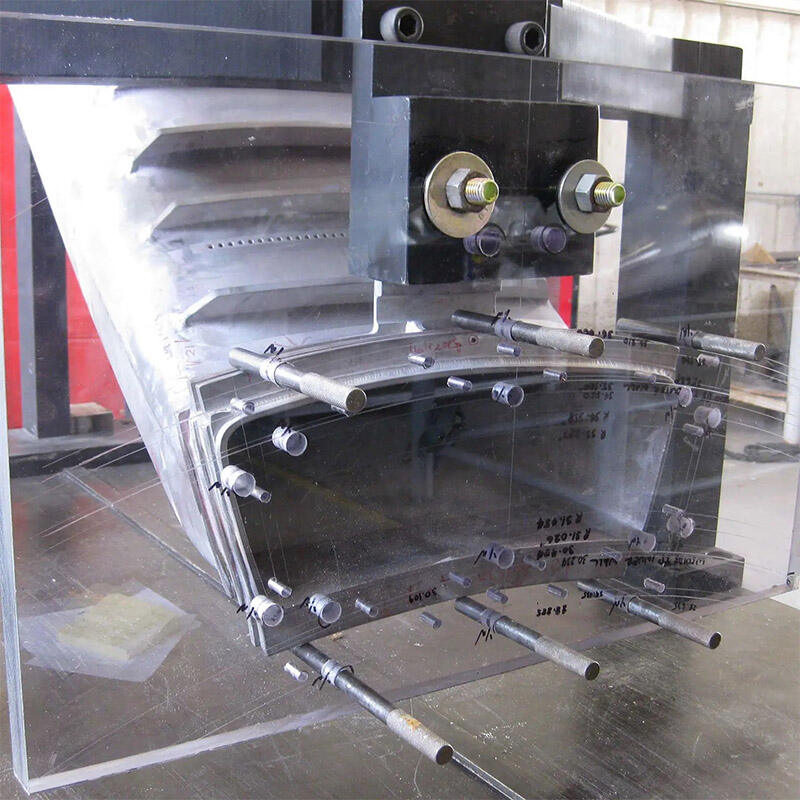

Our company can fabricate highly precise and stable turbine parts through casting forging, and CNC machining. Casting allows us to create components with complex forms, high strength and long-lasting. Forging can give parts a more durable and superior mechanical property. CNC technology for machining, on other hand, ensures high precision and consistency of every part, which reduces the chance of the chance of errors and producing substandard products. Our technical team that constantly carries the latest technological advancements and process improvement to make sure that our products are always at the top of the industry in terms of steam turbine casing. We're determined to meet our customers' demands for high-performance turbine components through continuous technological advancement.

We adhere to steam turbine casing of quality control in order to guarantee the performance and reliability of every component. Quality control is performed throughout the entire manufacturing process starting from the purchase of raw materials through the test of the finished product. In order to ensure that our product's quality is continuously improved, we also conduct regular audits and improvement. Our goal is to win the trust and cooperation of our clients by offering top quality products and to become a leader in the industry.

We offer comprehensive customer support that includes pre-sales consultation technical support as well as after-sales services to ensure that our customers have the best possible experience When it comes to the pre-sales phase our team of experts will be able to understand the needs of the customer in detail and provide the most appropriate product suggestions and solutions For technical support we offer complete guidance from selecting the product to installation and commissioning to ensure that our customers use our products without difficulty For after-sales support We have created an efficient service system that can respond swiftly to customer issues and requirements and offer prompt and effective solutions We aim to build long-term relationships with our customers and earn their steam turbine casing and respect by providing quality service