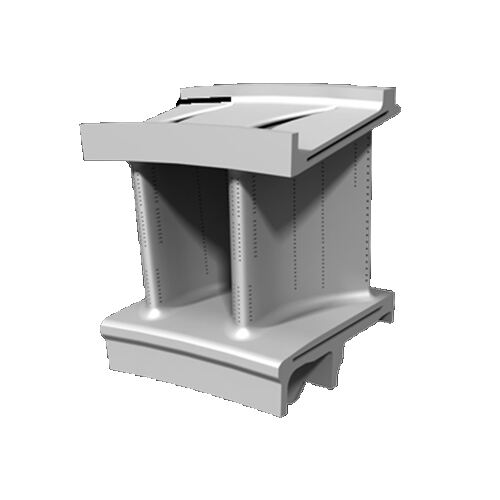

An airplane engine has a very critical component called LPT blade. It aids in the functioning of the engine and ensures the steady operation of the airplane. The stator ring is a stationary part that sits between the two most crucial parts of an engine : the turbine and the compressor. This special ring helps guide the air that passes through the engine so that it can better do its job and in more of an efficient manner. The engine itself might not work as well without the stator ring, which might influence how well the airplane flies.

PT stator rings are used to reduce the turbulence of the air inside the engine. The first thing that air does is go through the compressor when entering the engine. The compressor compress the air and heat it up to prepare it for the next stage. From here the air enters a part known as the combustion chamber. The air then travels to the combustion chamber where it combines with fuel and ignites. This process produces hot gases that cause the turbine to rotate and produce power. The stator ring is a key component for ensuring uniform airflow across turbine blades. This improves the performance of the engine leading to more power with lesser fuel consumption.

High-quality PT stator ring not only is the necessity of normal work of detonating gas in airplane engines, but also is the key factor to decide the sealing performance of airplane engines. Top-notch stator rings are meticulously crafted to fit snugly in the engine. A perfect fit is vital for this because it lets the ring circulate air like it’s supposed to. A well-stator ring allows to get better engine efficiency implying in a power boost with less fuel. By collecting them all, it is possible to save some cash and help alleviate waste from the environment. And a good-quality stator ring also makes the engine last longer, which is good news for airplane companies as well as their passengers.

O.B.T work all the time to improve PT stator rings utilized in aircraft engines. They are ever on the lookout for new methods to optimize their designs. Rings are designed, using cutting edge technology including computer modeling and computer-aided design (CAD). Its state-of-the-art facilities allow them to create very precise and dependable stator rings. By having this need better attended to by the stator rings, which are what make these improvements possible, safer, more efficient flights can be assured for all.

There are important parts for the performance of an aircraft enginePT stator rings. They perform a vital function keeping the engine running smoothly and supplying them with the power required to maintain an aircraft soaring in the air. At O.B.T, we innovate and improve all day, every day, taking advantage of technology that is a world apart from what was used before, we are dedicated to improving PT stator rings. Aiming to boost airplane engines and making skies safer and more reliable. Keeping people safe while they fly around the world, that all comes down to airplanes flying safely and efficiently.”

We adhere to the strictest standards of quality control to ensure the reliability and performance of each component Quality control is conducted throughout the entire process of production from the purchase of raw materials to the testing of the PT stator ring In order to ensure that our product's quality are constantly improved we perform regular audits and improvements Our aim is to win the trust and continue to work with of our customers through providing quality products that are of the highest standard and to be a leader in the industry

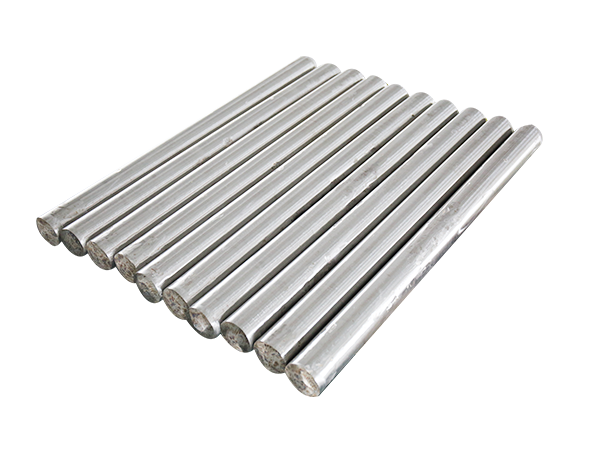

We can create turbine parts with high precision and consistency through PT stator ring, machining and forging processes. Casting allows us to create parts with intricate designs, strong and durability. Forging gives parts a more durable and superior mechanical property. CNC machining technology, on the contrary, provides the highest precision and accuracy of every part, which reduces the chance of the chance of errors and producing substandard products. Our experienced technical team is always working on technological innovations and process improvements in order to ensure that our products remain at the leading edge of industry technology. We are committed to meeting the demands of our clients for high-performance parts by constantly advancing technology continuously.

Our complete customer service package includes pre-sales consultation technical support and after-sales assistance to ensure our customers have the best possible experience When it comes to the pre-sales phase our experienced team will understand the customer's needs in detail and provide the most suitable suggestions and solutions In terms of technical support we offer full guidance from product selection until installation and commissioning to ensure that our customers use our products efficiently When it comes to after-sales service we have developed an PT stator ring service system that can respond swiftly to customer issues as well as needs and provide quick and effective solutions We want to create long-lasting relationships with our customers and gain their trust and appreciation by offering high-quality services

Our company provides PT stator ring, and we is able to manufacture turbine parts from many high-temperature aluminum alloys in order to satisfy the demands of customers. Our flexible production flow and advanced technology for processing and our ability to satisfy particular requirements, like size and shape, as well as performance will allow us to meet any need. We work closely with customers to fully comprehend their requirements and applications scenarios and provide them with expert assistance and suggestions. We have a broad range of materials and processing capabilities to meet the special demands of various industries and applications. Our clients can improve their competitiveness on the market by offering customized services that optimize performance and reduce cost.