turbine blades are a key component of wind turbines. They are able to capture the energy from the wind and convert it into electricity that can power our homes and schools. These blades are designed to withstand extreme weather conditions, including high winds and extreme heat and cold. It also means they are able to work in a variety of climates, regardless of how extreme they may get.

The tech that goes into making PT rotor blades is what makes them so special. They are constructed of lightweight yet strong materials, including carbon fiber and epoxy resin. Manufactured from super-strong yet lightweight materials. This makes the blades damage-resistant because of the weather and helps them sustain for a longer duration without getting faulty.

Aerodynamics is one key aspect of second stage turbine blade technology. That big word means how air flows around things. The shape of the blade is specifically designed to allow the wind to flow easily through the structure. This allows them to catch as much of the wind as possible, allowing them to generate the MOST amount of energy. To aid with this, the surface of the blade has a special coating that decreases drag, or resistance, as it is pulled through the air. It greatly improves the ability of the blades to transform wind into energy.

That’s where PT rotor blades really come into their own.” They are so advanced in terms of design and technology that they are capable of harnessing even the lightest breeze and converting it into useable electricity. This is extremely important because it allows wind energy to be a realistic option in locations not known for strong winds. PT rotor blades enable more locations to access wind power, as they are capable of capturing more energy.

Thanks to PT rotor blades it is possible to achieve the best performance level for wind turbines. That gives them a great advantage to produce clean and sustainable energy for the next decades. Wind energy not only reduces pollution but also helps to reduce our dependency on foreign oil and fossil fuels, which is good for our economy and environment. And this is good for our planet, and good for our economy.

Rotors blades of PT are Prepared with lot of care and precision. They also guarantee that they're perfectly balanced and aligned, an important aspect of performance. Properly-balanced blades aid in minimizing vibrations and noise. That matters because it means wind turbines are less obtrusive for people who live near them. Wind energy becomes more accepted by the communities, if you have a quieter turbine.

In conclusion, PT rotor blades are a key component in the construction of wind turbines also. IVD’s are prima facie integral components that enable clean and sustainable energy generation. To generate wind energy efficiently, there is no better rotor blade than the PT rotor, so featuring advanced technology and customized design.

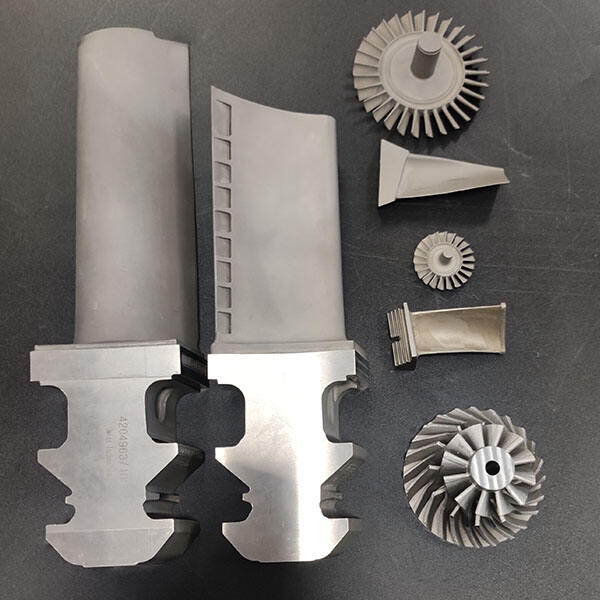

Our company is able create highly precise and reliable PT rotor blade by using casting, forging and CNC machine processes. Casting allows us to make parts with complicated designs, strong and long-lasting. Forging gives parts a higher mechanical property and durability. CNC technology for machining, on other hand, ensures an extremely high level of precision and consistency in each component, thus reducing the risk of manufacturing errors and resulting in substandard products. Our technical staff is constantly striving to improve technological innovation and process improvements to ensure that our products remain at the leading edge of industry technology. We're committed to meeting the demands of our customers for high-performance turbine parts through constant technological advancement.

Our company adheres to strict quality control guidelines to ensure excellent performance and PT rotor blade of every component. Quality control is carried out throughout the entire process of production beginning with the purchase of raw materials to the test of the finished product. We also regularly conduct quality audits and adjustments to ensure constant enhancement of the product's quality. Our goal is to win the trust and cooperation of our customers by providing high-quality products and to become an industry leader.

We provide a PT rotor blade, including pre-sales consultation as well as technical support and after-sales services to ensure that our customers enjoy the most enjoyable experience. Our expert team will assess the needs of customers and offer appropriate products and solutions. Concerning technical assistance, we provide all the guidance needed from choosing a product to installation and commissioning to ensure that customers can use our products without difficulty. In terms of after-sales service we have designed a flawless service system to react quickly to customer concerns as well as needs, and provide quick and effective solutions. Our goal is to develop long-term relationships, and gain customers trust and satisfaction through superior customer service.

Our company provides specific services that is able to manufacture turbine parts from an array of high-temperature metals to meet customer needs. If it's a particular shape, size or performance requirement, we are able to meet it using our flexible production process and the latest process technology. We stay in close contact with our clients to comprehend their individual requirements and scenarios, and provide them with expert technical guidance and solutions. We have a broad range of materials and processing capabilities to meet the unique needs of various industries and applications. Our clients can improve their PT rotor blade by providing specific services that maximize performance and reduce costs.