This model optimizes energy use, which makes machines more efficient and better for the environment through turbine diffuser technology. It also indicates that these machines can accomplish several work without using overhead power. A Turbine diffuser are unique design of shape that helps for the fast moving air to slow it down and spread in turbine. They do this so that the air will move easier through the engine and make more power. This is crucial because the better a turbine can make use of air, then more energy it yields.

On the whole, it's clear that even relatively advanced diffuser designs can make a big difference to how turbines behave. Turbine diffusers coerce the rapid airstream through them to slow it down The air produced in turn slows the faster turbine, allowing more energy to be harvested by each individual windmill. Because just like different tools are better suited for particular jobs, some turbine types might benefit from a specific diffuser shape. So, researchers and engineers constantly test new wind turbine designs to optimize how turbines perform.

Smart diffuser systems play a major role in increasing the power generated by turbines. Energy is generated by spinning a fan in turbines. Turbine diffusers The turbine diffusers help regulate the airflow around the fan blades. In other words, it optimizes airflow for the fan to make more energy helping you gain even moar power from your turbine. This process is key, as scientists are constantly investigating and testing different diffusers to figure out which work best and which can help a turbine achieve maximum potential.

Turbines are able not only to reach, a higher power output using diffuser stealth technology but they also become more powerful and longer-lived. The benefit of the turbines generating more power for less effort means that they do not have to work as hard. This is a great thing because it will make them last longer and save you on both repairs and maintenance. Strong and efficient turbines are also less likely to break down or cause problems, which is very important for safety and reliability.

The very secreto ingredientio of turbine diffuseronomics is the knowing how to make POWER many kiss in turban diva way. Power plants are using them to generate electricity from resources such as coal, oil or gas. In addition to that, they are also utilized in wind mills for the production of power from air circulating over buildings. In addition to automotive power generation, other industrial machinery can also be assisted in making better use of energy more effectively and efficiently thanks to a turbine diffuser. This not only streamlines the process resulting in potential cost savings for businesses.

Our company provides turbine diffuser and can make turbine components in many different high temperature alloys according to the requirements of customers. Whatever the size, shape, or performance requirement, we are able to meet it using our flexible production processes as well as our advanced processes. We collaborate closely with our customers to comprehend their needs and applications scenarios and then give them professional assistance and suggestions. We have a broad range of processing and materials to meet the unique requirements of different sectors and application. We help our clients improve their competitiveness in the marketplace by offering custom-designed services that improve performance and reduce costs.

We follow turbine diffuser for quality control to ensure the performance and reliability of every component. The entire process of production is subject to quality control, from the raw material purchase until the final testing of the product. We also regularly conduct quality audits and improvements to ensure continuous improvement of product quality. We are determined to gain the trust of our clients and to maintain their long-term relationship by offering high-quality products.

Our customer support is turbine diffuser and includes technical assistance, pre-sales advice and after-sales assistance to ensure our customers have the best possible experience. Our experienced team will review the needs of customers and offer the most effective solution and recommendations for the product. We provide technical support starting with the selection of products to installation and commissioning. This guarantees that our clients are able to enjoy our products without problems. We have a well-developed after-sales service that allows us to react quickly to customer requests and problems and provide quick and timely solutions. We strive to establish long-term relationships with our customers and earn their trust and respect by providing quality service.

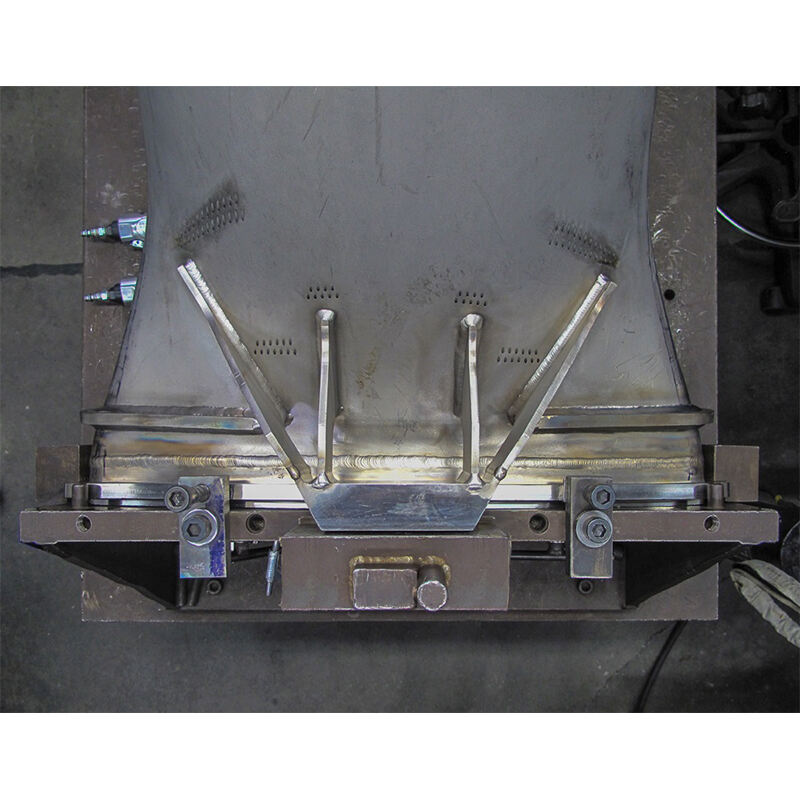

We can create turbine parts with high precision and consistency through turbine diffuser, machining and forging processes. Casting allows us to create parts with intricate designs, strong and durability. Forging gives parts a more durable and superior mechanical property. CNC machining technology, on the contrary, provides the highest precision and accuracy of every part, which reduces the chance of the chance of errors and producing substandard products. Our experienced technical team is always working on technological innovations and process improvements in order to ensure that our products remain at the leading edge of industry technology. We are committed to meeting the demands of our clients for high-performance parts by constantly advancing technology continuously.