Wheel compressors are used to raise the air pressure in an area. These machines are of a great help to the businesses as well for both industrial and household usages. Wheel Compressors Advantages: - Very High Efficiency Wheel compressors have an much higher efficiency even up to 30% compared with another compressor technologies Energy Saving This great feature results in big savings on your energy bills which makes them ideal for the user.

Wheel type compressors are not only efficient, but they also last for a life time. These grinders are ideal for businesses searching the market for long-lasting tools that can stand up to constant use while still steering clear of expensive breakdowns. Also these compressors are very easy to maintain that makes them as the best choice for business people who do not like down time.

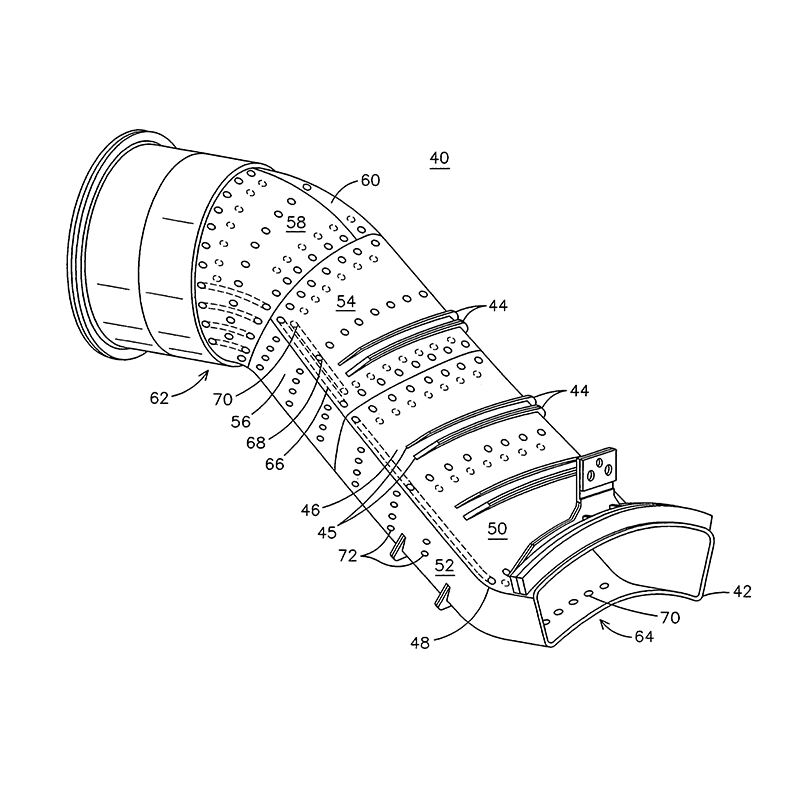

Wheel compressors work on a really quite simple however intelligent principle. Dynamic compressors work by reducing the volume any fluid of gas otherwise liquid can be achieved with a series rotating blades impedance to increases (i.e.. The rest of that air, which was to be compressed goes towards other uses including everything from machinery applications all the way down to inflating a tire.

Wheel Compressor - Rotors can vary in size and design to accommodate a wide range of load requirements. We've seen models that you could easily slide under a desk due to its size, and others are roughly as massive in scale meaning if introduced into the corner of largest warehouse you can find it almost filled compressed air on itself. But, no matter the scale all-wheel compressors work profoundly with its mechanism of operation.

The efficiency is contributed by a combination of modern technologies employed in wheel compressors. The application of cutting-edge lightweight and robust materials which are crucially important in the reduction of noise level is also impressively low. Wheel compressors are driven by crankshafts that connect to a variable-speed control-a big tech advantage as the compression rate can be slowed down and sped up on demand/#, capable of modulating its speed in relation to how much compressed air is required. It is this real time adjustment that enables a variable screw compressor to be idle when demand for air drops and then ramp up output the moment it has been determined compressed air needs have increased.

Suitable for air packing during motion or when considering economy, a wheel compressor... to be a good choice in choosing the right wheel compressor, many reasons behind it that makes this process much more complex than what one might think. Eg Size Of Area Needing Compressed Air Not Just Your Requirements But Also With What Pressure Levels And To An Extent, Budget Guidelinesism. One more point is current horse power rating and how that relates to the compressor, or motor driving your turbo wheel. More Horsepower = More Air Compression You also need to look at the air volume output; this is measured in cubic feet per minute (CFM) of your compressor.

Furthermore, the compressor is quite loud so maybe not for an office job that requires communication. Thus, selecting a compressor having in-built noise-reducing features or one which is purposely built to produce lesser sound overall aids in retaining an efficient work environment.

The wheel compressors are reshaping the way industry and household operate. Nevertheless, given their unrivaled performance and the safety of service as well as providing our customers with a sturdy freestanding space solution they are undoubtedly the preferred option available for individuals who desire compact air products. Through their assistance in "levelling the playing field", they help to give small operations a competitive advantage and increase the number of smaller firms able to compete with more powerful competitors. As a self-contained and dependable WCM, it can allow smaller enterprises to leverage advanced process control utilizing only the monies required.

More over,wheel compressor to maintain environmental sustainability by decreasing the waste and affects related with conventional way of operating a compressor. There are traditional models that require more energy and therefore emits a lot of heat, wheal compressors come as an excellent option to avoid this massive waste. It helps businesses to work in a green manner and not harm mother Earth.

In conclusion, wheel compressors are a breakthrough (and probably end) technology trend in compressed air systems Due to their bright future as well-inverse side of traditional screw compressor used for years. With an excellent compressor design and commercial residential friendly, these units make a great recommendation. In this manner, the users are now able to understand how such wheel compressors work as well as knowing what constitutes important selection criteria by which they can determine that it maybe a suitable compressor for them. Future Advancements An optimistic future seems to await wheel compressors, or so the development of new technologies and designs would suggest.

Our company adheres to strict quality control guidelines to ensure excellent performance and wheel compressor of every component. Quality control is carried out throughout the entire process of production beginning with the purchase of raw materials to the test of the finished product. We also regularly conduct quality audits and adjustments to ensure constant enhancement of the product's quality. Our goal is to win the trust and cooperation of our customers by providing high-quality products and to become an industry leader.

We offer a comprehensive customer service which includes pre-sales advice as well as technical support and after-sales support, in order to ensure our customers get the best experience. In the wheel compressor the team's professional staff will understand the customer's needs in detail and provide the most appropriate suggestions for products and solutions. We provide technical support starting with the selection of products, through installing and commissioning. This guarantees that our clients are able to use our products without any problems. We have an established after-sales process that allows us to quickly respond to customer concerns and issues and to offer effective and prompt solutions. We want to create long-lasting relationships with our customers and gain their trust and satisfaction through offering high-quality services.

Our company is able produce highly accurate and consistent turbine parts by casting, forging, and CNC machining processes. The casting process allows us to produce parts with intricate shapes and strong durability, while the forging process gives the parts better wheel compressor and longer lasting. CNC machining technology, on the contrary, guarantees consistent and high-quality of every part, which reduces the chance of manufacturing errors and resulting in substandard products. We have a highly skilled technical team that constantly carries out technological innovations and process improvement to make sure that our products stay in the forefront of industry in terms of technological. We are committed to meeting the requirements of our customers for components that are high-performance by developing technology continually.

Our company offers custom-designed services and can make wheel compressor in an array of high-temperature alloys in accordance with customer specifications. Whether it is a specific dimension, shape or requirements for performance, we can accomplish it by using our flexible production process and cutting-edge process technology. We collaborate closely with our customers to comprehend their needs as well as the various scenarios they might encounter and then offer them expert assistance and suggestions. Our diverse selection of materials processing capabilities, processing capabilities as well as specific requirements to the application allow us satisfy the specific needs of various industries and application. With customized services, we help our customers optimize the performance of their products and reduce costs, and improve market competitiveness.