Hello there! Well, today we are going to be looking at something very cool–the combustion chamber. You are probably wondering, “What is this‽ “Never heard of it before, no problem we will be describing in simple words then you can understand what are all talking about.

If that was a lot to read, the question still remains what is a combustion chamber? If you want to keep it simple, a combustion chamber is this special part of any machine that can burn things using air. Think when you lit a candle. Because the fire will die down if it does not have air to keep itself burning, right? Machines operate on a similar concept. The engine has to have air in order to burn fuel, and produce power. This chamber is called the combustion chamber, and it serves as a place where this critical burning process takes place.

You might now be thinking that if high pressure is so readily available, why do we even need a combustion chamber? That’s a great question! In fact, many of the machines that we see and use everyday rely on combustion chambers to operate properly. For example cars, aircraft and some boats use combustion chambers to help drive their engines. We would not have any use of these machines if we did nothave the combustion chambers so that our life will be kept on becoming more hectic.

Spark Plug – Similar to a small match, which ignites the fuel inside of the chamber. Because you will be lighting a fire using the match. And it should work when held up to your flame, right? This applies for spark plug also. If the spark plug is not working correctly; Therefore, fuel does not burn properly and then it Will Not Run as Well as It Should.

The final thing that needs to be done for it is just run well overall would more or less cover itself— someone has to take care of the machine. That involves tasks such as oil and filter changes, inspecting spark plugs to see if they are functioning properly or cleaning the air intake valve so that all other systems continue working efficiently. All of these steps make the combustion chamber perform optimally over a long period.

Now, we will discuss all of the types of combustion chambers. There are many varities with their own pros and cons. The majority of SPI that you come across are gasoline engines and cars. This is not good, because they work quickly and are effective in making energy whereas it can build lot of pollution to our environment

Diesel engines, on the other hand are a different type of combustion chamber that is popular in larger vehicles such as trucks and buses. In addition to direct CO2 emissions, diesels are typically more fuel efficient than gasoline engines in the first place anyway and can produce less of some harmful pollutants. But diesel engine may expensive to install and maintain, you should take this into consideration.

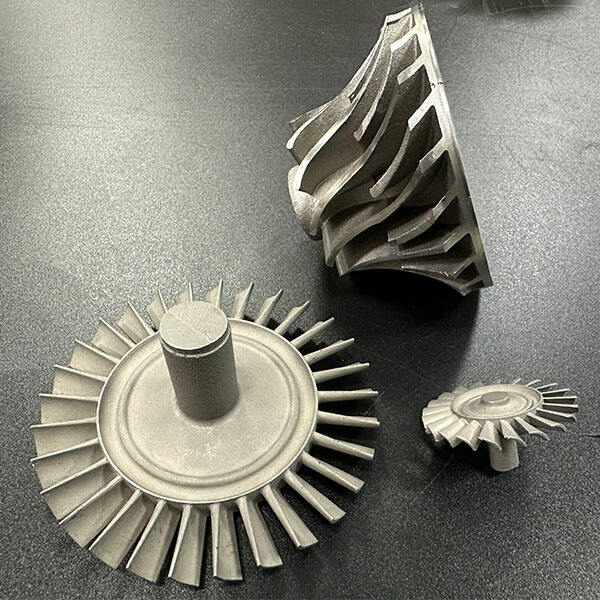

Our company has the ability to create highly precise and reliable turbine parts through casting combustion chamber, and CNC machining processes. Casting allows us create components with complex designs, strong and long-lasting. Forging provides parts with a better mechanical quality and longer durability. CNC machining, on the contrary offers high precision and consistency for every component. This reduces errors and inferior products. Our technical staff is constantly developing technological advancements and process improvements to ensure our products are at the forefront of industry technology. We're committed to meeting our customers' demands for high-performance turbine components by continual technological advancement.

Our company follows strict combustion chamber standards in order to ensure excellent performance and dependability of each component. Quality control is conducted throughout the entire production process beginning with the purchase of raw materials through the test of the finished product. To ensure that the quality of our products is continuously improved, we perform regular audits and improvements. We strive to earn the trust of our clients and their long-term partnership by providing products of high-quality.

Our company offers a variety of customized services, and produces turbine components from an array of high-temperature combustion chamber to meet the requirements of our customers. Our flexible production process and advanced technology for processing and our ability to satisfy specific requirements, such as size shape, performance, or shape, allows us to achieve every need. We communicate closely with our customers in order to fully understand their individual requirements and situations and offer expert advice and solutions. We offer a wide range of materials and processing capabilities to meet the specific demands of various industries and applications. Through customized services, we help our customers optimize product performance and efficiency and increase competitiveness in the market.

Our customer support is comprehensive and includescombustion chamber, technical support, and after-sales services to ensure that our customers get the best experience possible. Our team of experts will evaluate the requirements of the customer and offer appropriate product solutions and suggestions. We provide technical support starting with the selection of products to installation and commissioning. This ensures that our clients are able to use our products without any issues. We have a well-developed after-sales process that allows us to swiftly respond to issues and needs of customers, and to provide effective and prompt solutions. We are determined to develop long-term relationships with our clients and gain their trust and respect by offering high-quality services.