For all of your compressor wheel machining, O.B.T is the machine shop you can rely on to deliver excellent results. From the quality of materials to being able to turn our compressor wheel around faster in wholesale, O.B.T performs in every aspect of compressor wheel production.

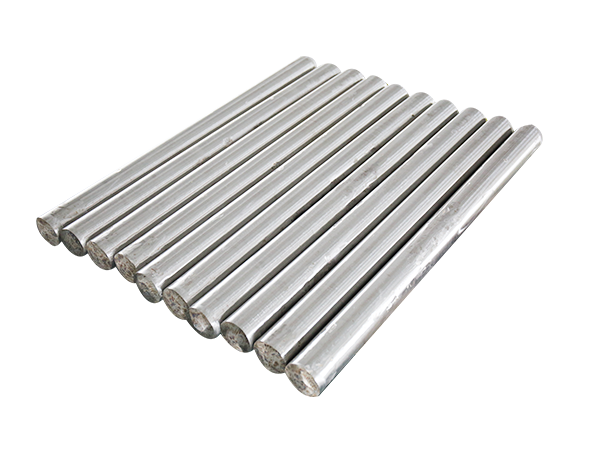

At O.B.T., we know that the best material is of utmost importance when it comes to compressor wheel machining. We are using high quality imported aluminum alloy materials. These are the stuff that makes our turbo compressor wheels are capable for high temperature and pressure, keeping its best performance in different requirement. So, with the use of high-grade materials, we assure that our wheel compressor will be up to the highest quality and reliability standards.

One of the major benefits by choosing O.B.T for compressor wheel machining, is our quick turnaround time on wholesale orders. We have optimized the production flow to minimize cycle time compressor wheel turbo in bulk quantity. Whether you are needing larger orders for industrial use or a supplier to deliver consistent shipments, O.B.T can serve you with quick turnaround times. Our dedication to quick delivery separates us from the rest, enabling our customers to be prepared and process orders quicker than ever before.

At O.B.T we are leading in the use of cutting edge technology when machining compressor wheels. Our advanced machinery enables us to develop compressor wheel design of high quality that will meet the highest requirements. One of the technologies I trust in is computer numerical control (CNC) processing. This allows the accurate accuracy and repeat ability in machining of compressor wheels as a result. Also, for the detailed design of compressor wheels, we apply computer-aided design (CAD) in order to obtain accurate blade and contour profiles before machining. This guarantees the end result is as precisely as the spec required and most economical.

Here are O.B.T we have a dedicated workforce of highly skilled machinists that have many years’ experience machining compressor wheels. You can tell their touch with everything you see they have made. Every compressor wheel machining is milled from forged aluminum and X-rayed for maximum quality standards. Our skilled workers take pride in producing excellent compressor wheels which meet and exceed the highest standards. Thanks to the expertise spun into these, we can offer our customers quality compressor wheels that are long lasting and still deliver unrivaled performance.

We provide a Compressor wheel machining, including pre-sales consultation as well as technical support and after-sales services to ensure that our customers enjoy the most enjoyable experience. Our expert team will assess the needs of customers and offer appropriate products and solutions. Concerning technical assistance, we provide all the guidance needed from choosing a product to installation and commissioning to ensure that customers can use our products without difficulty. In terms of after-sales service we have designed a flawless service system to react quickly to customer concerns as well as needs, and provide quick and effective solutions. Our goal is to develop long-term relationships, and gain customers trust and satisfaction through superior customer service.

Our company offers specific services that is able to manufacture turbine parts from various high-temperature alloys in order to satisfy the demands of customers. Our flexible production flow as well as our state-of-the-art process technology and our ability to satisfy particular requirements, like size and shape, as well as performance will allow us to meet every requirement. We are in constant contact with our customers in order to fully understand their needs specific to them and the application scenarios, and provide them with expert technical guidance and solutions. We have a rich selection of processing and materials that can meet the Compressor wheel machining of various sectors and application. Through customized services, we assist our customers in optimizing their product performance and cost, and improve market competitiveness.

Our company is able create highly precise and reliable Compressor wheel machining by using casting, forging and CNC machine processes. Casting allows us to make parts with complicated designs, strong and long-lasting. Forging gives parts a higher mechanical property and durability. CNC technology for machining, on other hand, ensures an extremely high level of precision and consistency in each component, thus reducing the risk of manufacturing errors and resulting in substandard products. Our technical staff is constantly striving to improve technological innovation and process improvements to ensure that our products remain at the leading edge of industry technology. We're committed to meeting the demands of our customers for high-performance turbine parts through constant technological advancement.

We adhere to Compressor wheel machining of quality control in order to guarantee the performance and reliability of every component. Quality control is performed throughout the entire manufacturing process starting from the purchase of raw materials through the test of the finished product. In order to ensure that our product's quality is continuously improved, we also conduct regular audits and improvement. Our goal is to win the trust and cooperation of our clients by offering top quality products and to become a leader in the industry.