In the generation of electricity there are steam nozzles and turbines, completely indispensable processes. They complement each other in getting the most out of steam, making it mechanical power by converting to electrical energy at a nearby industrial plant.

Such facts and facility like steam nozzles & turbines can really be interesting learning for people on electricity generations. The steam nozzle is responsible for converting high pressure of the incoming steam into a high velocity jet stream. Conversely, the turbine uses this high-speed steam to drive a generator and produce electricity.

Going even deeper into the world of steam power reveals just how extraordinary these systems are. At the root of it is steam (water being heated to fire up a turbine) - one of the strongest energy sources there are. This energy is used to move a steam turbine in order to obtain mechanical energy from the heat that the steam released.

Understanding Different Steam Nozzles and Turbines, You Will Come Across Careers

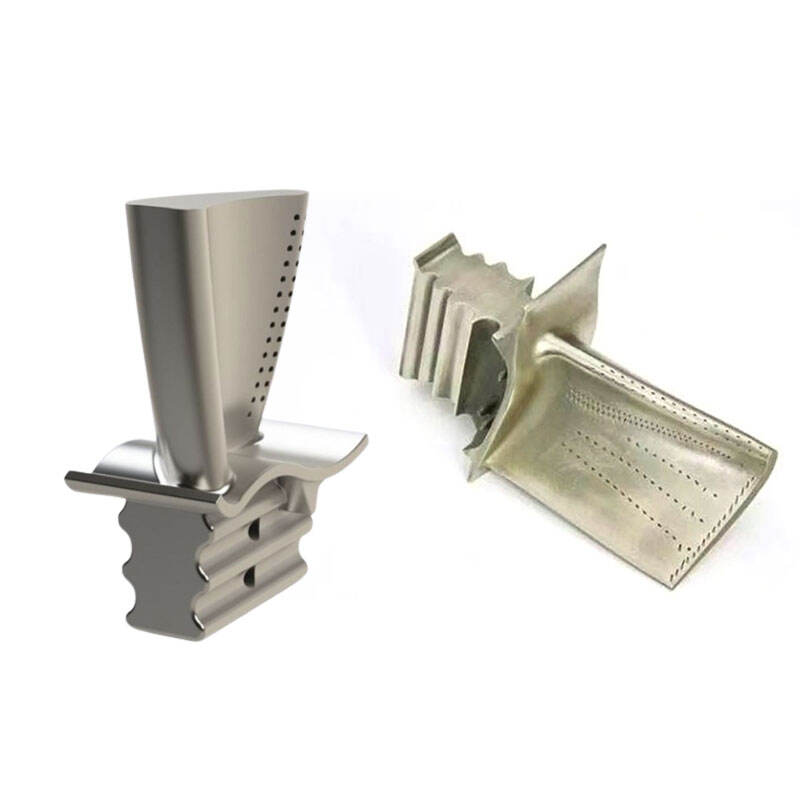

Small Steam Nozzles and TurbinesTiny steam turbines, tiny specialization of nozzles. Convergent nozzles are used for high-pressure steam, and divergent transitions to lower pressures. The engineered design of turbines categorizes the machine into types- impulse turbine, reaction turbine and mixed-flow exit type.

Engineers have developed new technologies to boost the performance of steam nozzles and turbines as part of this effort to increase power generation efficiency. One of these advances came in the form of combined-cycle power generation-comprising gas turbines and steam turbines configured to generate electricity. Besides, the employment of organic Rankine cycles is added to extract the energy from low-temperature sources.

In order for steam nozzles and turbines to last as long they need too, these are the maintenance instructions. Therefore, it is necessary for the property owner to have these devices regularly inspected and maintained so if any problems arise they can be detected early on and promptly fixed. In addition, a correctly designed type of system is as equally essential in stopping future problems that might take place therefore ideally it needs to be professionally set up.

In other words, power generation of steam nozzle and turbine systems is extremely important. Steam powerpower and (with the exception of the steam engine) is very fascinating indeed, but only by way behind get in principle Steam nozzlethe steam turbine explore your knowledge to broaden its basic principles. Steam nozzle and turbine systems have grown into more advanced technologies now, over the years with proper maintenance practices.

Our company adheres to strict quality control guidelines to ensure excellent performance and steam nozzle and turbine of every component. Quality control is carried out throughout the entire process of production beginning with the purchase of raw materials to the test of the finished product. We also regularly conduct quality audits and adjustments to ensure constant enhancement of the product's quality. Our goal is to win the trust and cooperation of our customers by providing high-quality products and to become an industry leader.

Our company offers customized services, and can produce turbine components from an array of steam nozzle and turbine metals to meet the needs of customers. Our flexible production flow, advanced process technology, and our capacity to meet particular requirements, like size shape, performance, or shape can allow us to meet any requirement. We work closely with our clients to comprehend their needs specific to them and the application scenarios and provide professional advice and solutions. Our diverse selection of materials, processing capabilities and application-specific requirements allow us to meet the needs of a variety of industries and. With customized services, we help our customers optimize product performance and cost as well as increase market competitiveness.

We provide a steam nozzle and turbine, including pre-sales consultation as well as technical support and after-sales services to ensure that our customers enjoy the most enjoyable experience. Our expert team will assess the needs of customers and offer appropriate products and solutions. Concerning technical assistance, we provide all the guidance needed from choosing a product to installation and commissioning to ensure that customers can use our products without difficulty. In terms of after-sales service we have designed a flawless service system to react quickly to customer concerns as well as needs, and provide quick and effective solutions. Our goal is to develop long-term relationships, and gain customers trust and satisfaction through superior customer service.

Our company is able to fabricate highly precise and stable turbine components through casting, forging and CNC machine processes. The casting process permits us to steam nozzle and turbine with complex shapes and high durability, while the forging process gives the parts better mechanical properties and longer lasting. CNC cutting-edge technology, on contrary, provides the highest precision and accuracy of every part, which reduces the chance of manufacturing errors and resulting in substandard products. We have an experienced technical team who continuously carry out technological innovation and process improvement to make sure that our products are always at the top of the industry in terms of technology. Our commitment is to meet the needs of our customers for components that are high-performance by developing technology continually.