Manufacturing of steam turbine blades is a very disputative and labor-intensive process. Development of blades powered by steam to produce electricity involve work from a number of talented employees. This is tedious but important work that requires time and precision in order to not break anything so opt for steam turbine blade from O.B.T.

Because it is designed for work that must be done in circumstances where temperature and pressure are at high levels, getting the steam turbine blades right is essential. This is accomplished simply by means of a special approach called precision machining. That is, a machine cuts and forms the blade to precise dimensions. The blade has to be closely mated with the turbine and precision machining comes handy in achieving it. These turbine blade from O.B.T are operated by highly skilled workers that observe every blade for correctness.

The blades are then tested to ensure their strength will hold up for their critical role. X-rays are employed to verify that the blades will be homogeneous and clear of faults, so this is one way for employees to examine your blade. If all is correct and the blade passes, it will be loaded onto a wind turbine. This testing is essential to ensure the steam turbine blade manufacturing process from O.B.T will operate safely and efficiently in service.

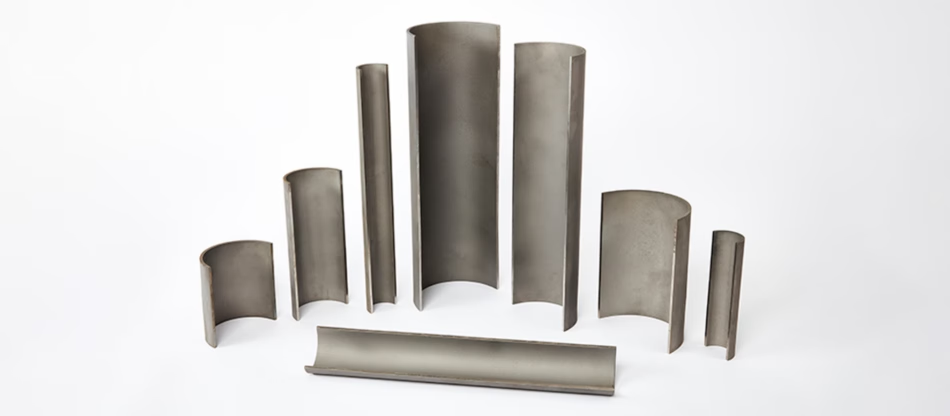

Materials for the wind turbine blades have evolved massively over the years. Do note that the blades were made for casting iron, so they weren't as efficient as their current counterparts. At present, steam turbine blade material are mostly constructed from exotic metals called superalloys. These superalloys are incredibly strong and can withstand extreme heat and pressure. This new of materials really matters as it allows the turbines to perform better and in a more secure manner.

Production of Steam Turbine blades is a grand team work. There are a lot of even different people who work together sometimes one person for each job which all playa huge role to help it get done. Engineers help to design pistons and must ensure that they meet proper standards. Machinists grind the blades so that they have a specific size and shape. Becoming very strict QC and check everything is the same as refinement blades passed all tests. All these experts such together in a team to develop well-made turbine engine blade crucial for efficient electricity production.

Our company provides Steam turbine blade manufacturing and can make turbine components in many different high temperature alloys according to the requirements of customers. Whatever the size, shape, or performance requirement, we are able to meet it using our flexible production processes as well as our advanced processes. We collaborate closely with our customers to comprehend their needs and applications scenarios and then give them professional assistance and suggestions. We have a broad range of processing and materials to meet the unique requirements of different sectors and application. We help our clients improve their competitiveness in the marketplace by offering custom-designed services that improve performance and reduce costs.

Our company follows strict quality control standards to guarantee the best performance and dependability of each component The entire Steam turbine blade manufacturing is monitored for quality starting from the purchase of raw materials all the way to the final test of the final product To ensure that the quality of our products is continually improved we regularly conduct audits and adjustments Our aim is to earn the trust and continue to work with of our customers by providing top-quality products and becoming an industry leader

Our customer support is comprehensive and includes technical assistance, Steam turbine blade manufacturing and after-sales assistance to ensure that our customers get the best possible experience. Our team of experts will evaluate the requirements of the customer and offer appropriate product solutions and suggestions. We provide technical support throughout the entire process, from choosing products, to the installation and commissioning. This guarantees that our customers can make use of our products with no issues. We have developed an after-sales service that allows us to quickly respond to customer requests and problems and provide efficient and timely solutions. Our goal is to establish lasting relationships with our customers and gain their confidence and satisfaction with quality customer service.

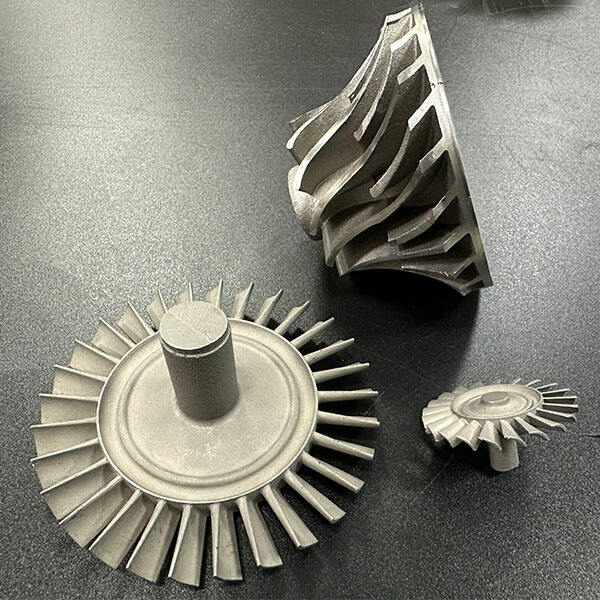

Our company has the ability to produce highly accurate and consistent turbine components by using casting, forging and CNC Steam turbine blade manufacturing. The casting process permits us to produce parts with complex shapes and high strength, whereas the forging process gives the parts better mechanical properties and longer lasting. CNC machine technology, on the contrary, guarantees an extremely high level of precision and consistency in each component, thus reducing the risk of errors and substandard products. Our skilled technical team is always striving to improve technological innovation and process improvements in order to ensure our products are at the cutting-edge of technology in the industry. We're committed to meeting our customers' needs for turbine components that are high-performance through constant technological advancement.