The steam turbine is a unique tool of changing the energy provided by steam into mechanical work. The O.B.T machine has a lot of blades and they run when steam passes through them. The Importance of These BladesThese blades are essential for the proper and efficient operation of this machinery. Without those steam turbine wheel, the steam turbine cannot create energy.

Strong materials are selected by the scientists for producing steam turbine blades These compounds should have to last at very high temperatures and under extreme pressure without breaking. These O.B.T blades are subject to wear and tear from operating under high steam temperatures. Scientists then also test other things that they think could work to get the best material. Occasionally —and when there is no material of their liking they even fabricate new ones from scratch that are more effective than ever.

In the passing decades, significant changes have been made to materials used in steam turbine blades by scientists. They started introducing new metals such as nickel and chromium Those metals help to promote strength and heat resistance of those materials, among other properties. Furthermore, scientists develop ingenious designs such as cooling channels located inside the blades. These channels help keep the white hot steam turbine blade of O.B.T cool as they are heated when steam is passed through them to make sure that it works better.

It is well known to the scientists that since the functioning of turbine blades has a lot to do with what material they have been made from. If the blades are in a material that isn't able to handle high temperature, they can shatter or collapse when heat passes through them. This can lead to serious problems and the steam turbine will fail condition, The function of nozzle in steam turbine materials used to build the blades need to be right, so they can do their job and are safe for both functionality purposes.

New materials are being constantly discovered by the scientists year after a new with improving technology in steam turbine blades. They are considering, for instance, the use of ceramics and glass-ceramics. Every person is aware of the range in which these materials are used as they can work at much higher temperatures and also produce very less friction. Which makes it easy for the blades to move and do their job better. The increased capability of steam nozzle and turbine can be crucial for electricity generation, and the new materials allow them to operate more efficiently.

Our customer support is comprehensive and includes technical assistance, Steam turbine blade material and after-sales assistance to ensure that our customers get the best possible experience. Our team of experts will evaluate the requirements of the customer and offer appropriate product solutions and suggestions. We provide technical support throughout the entire process, from choosing products, to the installation and commissioning. This guarantees that our customers can make use of our products with no issues. We have developed an after-sales service that allows us to quickly respond to customer requests and problems and provide efficient and timely solutions. Our goal is to establish lasting relationships with our customers and gain their confidence and satisfaction with quality customer service.

Our company adheres to strict quality standards to ensure the highest quality and the reliability of every component Quality control is carried out throughout the entire process of production from the acquisition of raw materials to the testing of the final product We also perform regular quality Steam turbine blade material and adjustments to ensure constant improvements in product quality Our goal is to win the trust and long-term cooperation of our clients by offering high-quality products and to become a leader in the industry

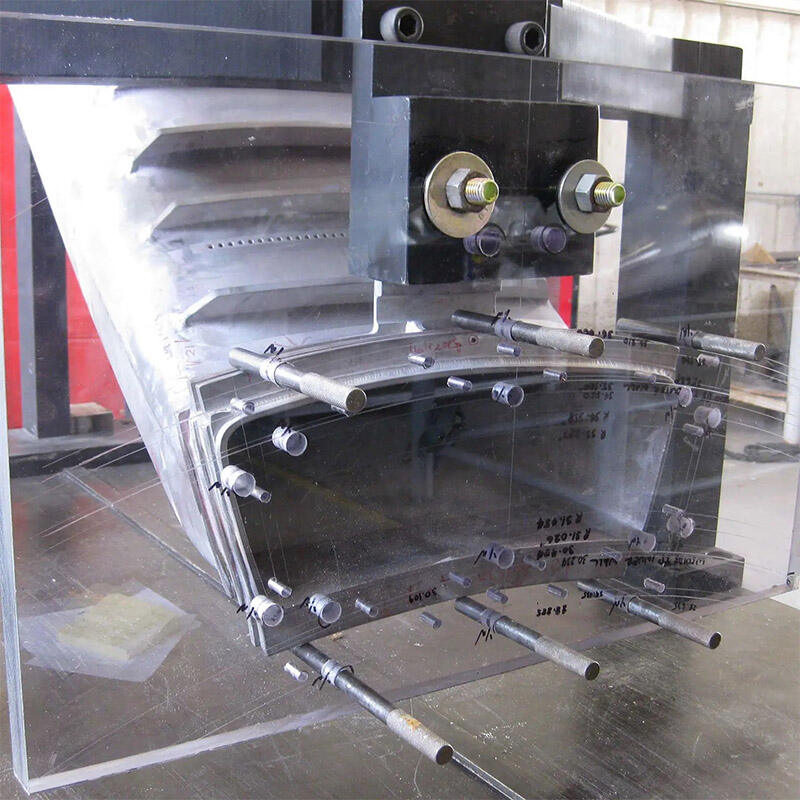

Our company has the ability to create highly precise and reliable turbine parts through casting Steam turbine blade material, and CNC machining processes. Casting allows us create components with complex designs, strong and long-lasting. Forging provides parts with a better mechanical quality and longer durability. CNC machining, on the contrary offers high precision and consistency for every component. This reduces errors and inferior products. Our technical staff is constantly developing technological advancements and process improvements to ensure our products are at the forefront of industry technology. We're committed to meeting our customers' demands for high-performance turbine components by continual technological advancement.

Our company provides Steam turbine blade material and can make turbine components in many different high temperature alloys according to the requirements of customers. Whatever the size, shape, or performance requirement, we are able to meet it using our flexible production processes as well as our advanced processes. We collaborate closely with our customers to comprehend their needs and applications scenarios and then give them professional assistance and suggestions. We have a broad range of processing and materials to meet the unique requirements of different sectors and application. We help our clients improve their competitiveness in the marketplace by offering custom-designed services that improve performance and reduce costs.