These turbochargers are force multipliers; tools that the engine itself uses to go faster and harder, just like in any form of competition. It does this by making the intake artificially bigger to help that engine breathe as efficiently as possible. What the turbocharger needs to work efficiently are, of course, a number of sets of what are called as turbocharger turbine wheels. This is somewhat critical due to the fact that these are effectively the little wheels which do a bunch of work when it comes to making a turbocharger function efficiently. Today, we are going to have a closer look at how O.B.T turbocharger turbine wheel constructs these wheels and what sets them apart if you must know.

This turbocharger compressor wheel is important because when the vehicle is running, it produces a large amount of heat. It has tiny wheels, the blades of which capture the spent engine exhaust gases. These move at a rapid rate of speed whenever the exhaust was flowing over them. This allows wheels to spin faster and makes further torque in less energy to be able to give pulse when the car is running. Of course-tapping those abilities down to such hadrons necessitates the wheel-making dexterity of a circus high-wire walker. A great deal of expertise and experience is also required to attend the care. We have been making them for years here at O.B.T and we know how to make them better than anyone else in the game!

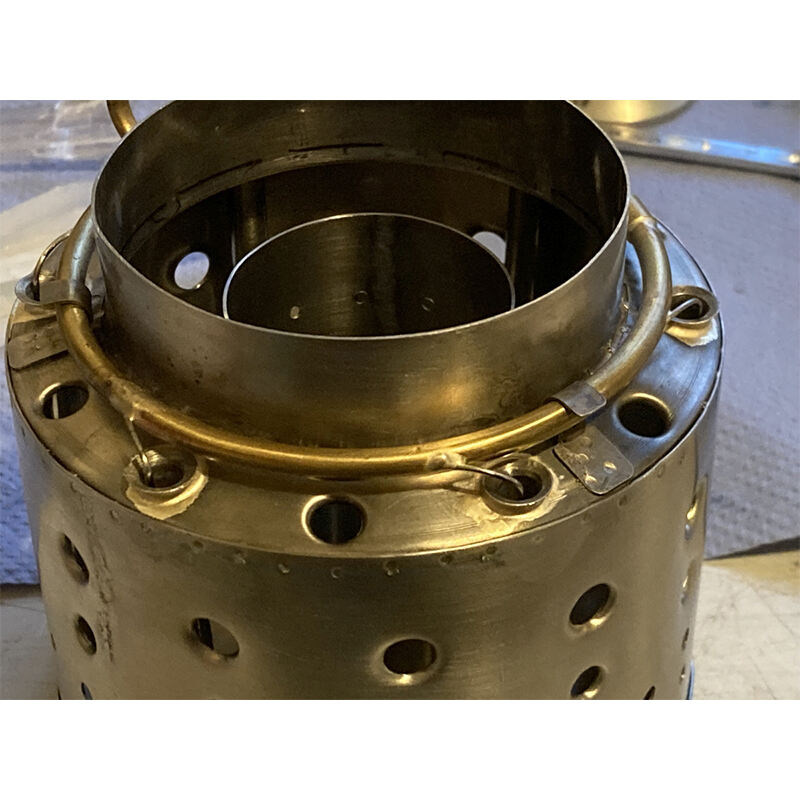

Shaping these turbocharger turbine rocks is an intricate procedure and partially reflectiveness. Background Firstly we should find a piece of metal that is appropriate and large enough to use as our turbine wheel. We would then cutter some metal and bend it to make a curved edge. Lathes are the machines we use to do this cutting. A turbocharger compressor wheel design cutting machine may be a use which uses sharp tools for material removal to cut the excess stress in a metal led body. Despite the fact that their life span has to end about every 15 minutes, digital equipment enables us to program the cuts to ensure that blades are just right for each game. It's also helping us make sure every blade is consistent — which, if we are trying to make a wheel that will actually spin in a circle around it; is pretty darn important.

The turbine wheels for the turbochargers can be made by casting and forging. The O.B.T turbocharger turbine wheel design first involves melting the metal to turn it into a liquid and make it cast able. Then when the metal cools, it will harden to take on its shape that was formed by the mold. This is called casting. Another is forging; where we heat the metal up to an amazing 2000 degrees Celsius and then deform it with a huge mechanical hammer.

Balancing is an important part of the manufacturing process when it comes to turbine wheels for turbochargers. That turbine wheel turbocharger said, however insignificant such a wobbles pin would be, a whirling wheel is going to shake like hell the great majority of times balance drifts even slightly off kilter.

We offer a comprehensive customer service that includes pre-sales consultation as well as technical support and after-sales assistance so that our customers have the most pleasant experience In the pre-sales stage our experienced team will understand the customer's needs in detail and provide the most appropriate suggestions for products and solutions For technical support we offer full guidance from product selection to installation and commissioning to ensure that our customers use our products with ease We have developed an after-sales program that enables us to quickly respond to customer concerns and issues and to provide effective and timely solutions We are determined to develop long-term relationships with our clients and Turbocharger turbine wheel manufacturing process their trust and satisfaction through offering high-quality services

Our company is committed to strict quality control standards to guarantee the best performance and reliability of every component Every step of the production process is controlled for quality starting from the purchase of raw materials all the way to the final test of the product We also carry out regular quality audits as well as adjustments to ensure constant improvements in product quality Our goal is to win the trust and continue to work with of our clients by offering top quality products and to become an Turbocharger turbine wheel manufacturing process

Our company has the ability to produce highly accurate and consistent turbine components by using casting, forging and CNC Turbocharger turbine wheel manufacturing process. The casting process permits us to produce parts with complex shapes and high strength, whereas the forging process gives the parts better mechanical properties and longer lasting. CNC machine technology, on the contrary, guarantees an extremely high level of precision and consistency in each component, thus reducing the risk of errors and substandard products. Our skilled technical team is always striving to improve technological innovation and process improvements in order to ensure our products are at the cutting-edge of technology in the industry. We're committed to meeting our customers' needs for turbine components that are high-performance through constant technological advancement.

Our company provides Turbocharger turbine wheel manufacturing process, and we is able to manufacture turbine parts from many high-temperature aluminum alloys in order to satisfy the demands of customers. Our flexible production flow and advanced technology for processing and our ability to satisfy particular requirements, like size and shape, as well as performance will allow us to meet any need. We work closely with customers to fully comprehend their requirements and applications scenarios and provide them with expert assistance and suggestions. We have a broad range of materials and processing capabilities to meet the special demands of various industries and applications. Our clients can improve their competitiveness on the market by offering customized services that optimize performance and reduce cost.