There are worlds of importance, for the making steam turbine blade and there many critical roles that has to be delivered by dozens more companies, the same as O.B.T's turbocharger compressor wheel. The manufacturing process of steam turbine blade is a special job and plays an important role in the production, so it takes more care with expert level to prepare this part. The firms have created steam turbine blades used in power plants across the world, providing energy to homes and businesses.

One of biggest company in this deomain is Siemens. This is what Siemens does, it has large areas in which they make machines for health purposes or like energy system to produce power so on. They manufacture steam turbine blades from durable materials that can withstand the harsh environments found in power plants. Their blades are used the world over in various power plants, and have a reputation for sturdy dependability.

New Techniques for Producing Steam Turbine Blades In steam turbine blade manufacturing, researchers are always looking for new ways to improve the process. They pay great attention to the type of materials used for fabrication blades They test materials that could resist under the extreme conditions of heat and pressure experienced in a power plant, allowing blades to have larger life expectancy while being more effective.

Another essential element in the manufacturing of steam turbine blades is their design, same with the diffuser turbine from O.B.T.

Steam Turbine Blades Types

The steam turbine blades fall into the following categories. While some blades are able to do a better job of moving air, thereby increasing their performance. Some is made to take wear and tear for longer periods while others are built even more tough. Blade manufacturers are always trying to find ways of increasing the efficiency in their blades so as not just generate more power but save money over time.

So what are some big ideas making their way through the industry today? 3D printing has to be on that list, identical to O.B.T's product jet engine turbine blades for sale. This technology is such an amazing fit, with everyone scrambling to make things faster and better in countless industries - Including for the production of steam turbine blades. One example of this is the use of 3d printing technology to produce molds and prototypes, some companies are now turning towards this method instead because it makes manufacturing much faster without as much waste.

Using robots is another breakthrough in the development of innovative ideas, which completely changes this age-old industry, same with the jet engine turbine blade manufacturing process supplied by O.B.T. Robotics technology has been leveraged in many manufacturing processes to simplify things and reduce the cost. Companies can automate the tasks that go into casting blades - As well quality-checking of those components using robots which would enable more reliable outcomes.

Automation is becoming an increasingly significant factor in the future of steam turbine blade manufacturing, as well as the O.B.T's rotor and stator in turbine. Free of human constraints, companies instead can save money and produce higher-quality blades by employing machines and robots into the process. Automation is used to speed up and improve the overall manufacturing process so you can produce more number of blades in less production time.

We adhere to Steam turbine blade manufacturers of quality control in order to guarantee the performance and reliability of every component. Quality control is performed throughout the entire manufacturing process starting from the purchase of raw materials through the test of the finished product. In order to ensure that our product's quality is continuously improved, we also conduct regular audits and improvement. Our goal is to win the trust and cooperation of our clients by offering top quality products and to become a leader in the industry.

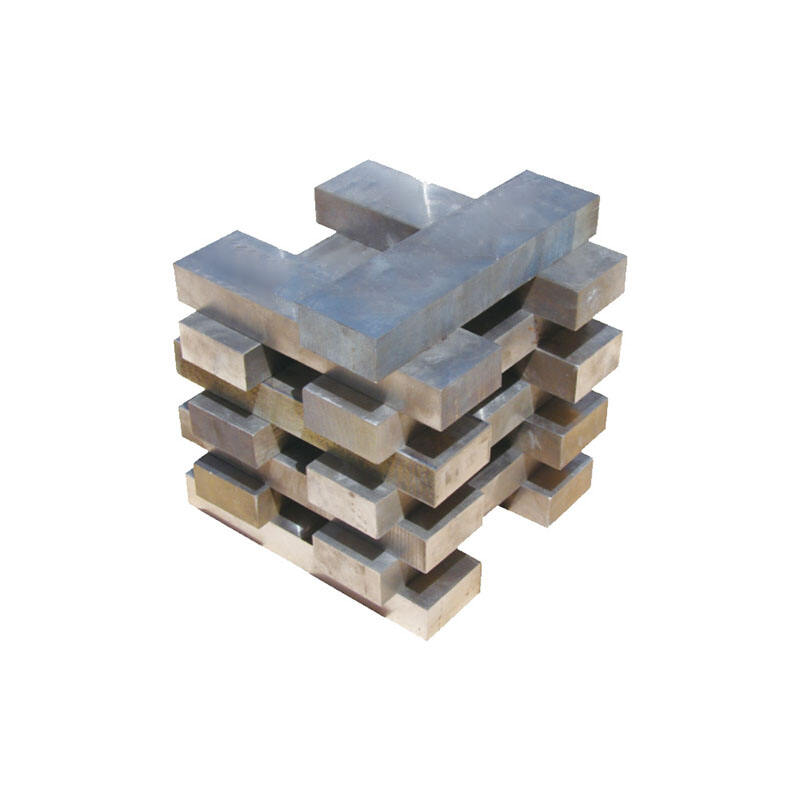

Our company has the ability to create highly precise and reliable turbine parts through casting Steam turbine blade manufacturers, and CNC machining processes. Casting allows us create components with complex designs, strong and long-lasting. Forging provides parts with a better mechanical quality and longer durability. CNC machining, on the contrary offers high precision and consistency for every component. This reduces errors and inferior products. Our technical staff is constantly developing technological advancements and process improvements to ensure our products are at the forefront of industry technology. We're committed to meeting our customers' demands for high-performance turbine components by continual technological advancement.

Our complete customer service package includes pre-sales consultation technical support and after-sales assistance to ensure our customers have the best possible experience When it comes to the pre-sales phase our experienced team will understand the customer's needs in detail and provide the most suitable suggestions and solutions In terms of technical support we offer full guidance from product selection until installation and commissioning to ensure that our customers use our products efficiently When it comes to after-sales service we have developed an Steam turbine blade manufacturers service system that can respond swiftly to customer issues as well as needs and provide quick and effective solutions We want to create long-lasting relationships with our customers and gain their trust and appreciation by offering high-quality services

Our company can provide customized services and is able to fabricate turbine components from an array of high-temperature alloys in accordance with the requirements of customers. No matter what Steam turbine blade manufacturers, size or performance requirement, we can achieve it with our flexible production process and cutting-edge technology for process. We work closely with clients to comprehend their needs as well as the various scenarios they might encounter and give them professional assistance and suggestions. We have a variety of materials and processing capabilities to meet the unique requirements of different industries and applications. We aid our clients in improving their competitiveness on the market by offering custom-designed services that improve efficiency and lower costs.