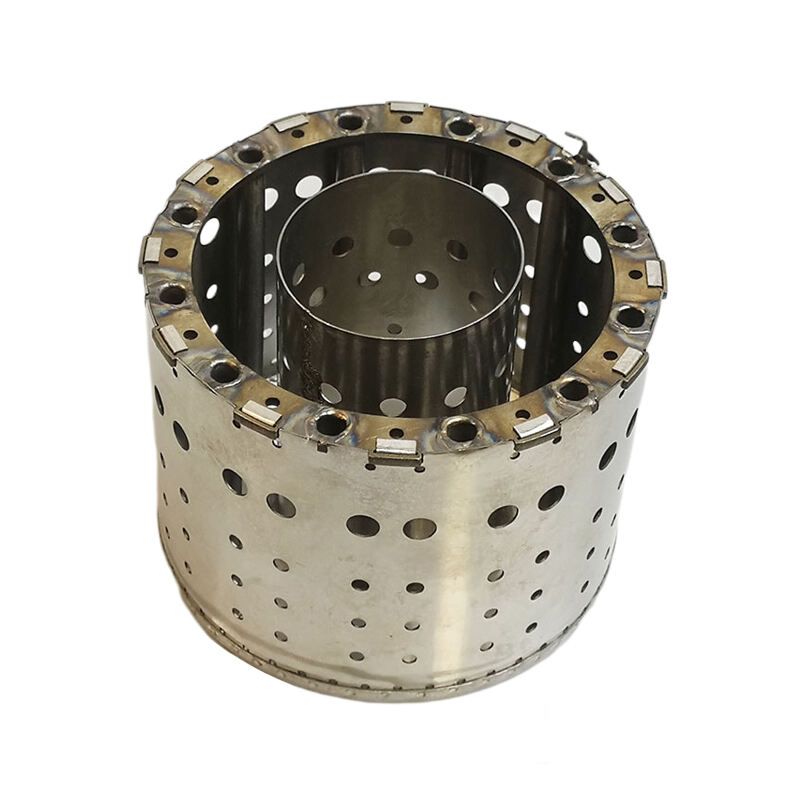

Možná jste někdy viděli letadlo na obloze? Vypadá úžasně, že ano? Kdy jste si naposledy připomněli, jak letadla získávají energii potřebnou k letu? Jednou z nejdůležitějších částí motoru letadla jsou tzv. kompresní listy. I když je to jedna z nejmenších součástí, je pružná a klíčová pro pomáhání letadlu vyvinout potřebnou sílu k odletu.

Návrh lopatky kompresoru je téměř uměleckou prací sama o sobě. Je nutné zajistit, aby měla lopatka správný tvar a kontury. Musí být také odolná a schopná vydržet extrémně vysoké teploty za celé hromady tlaku. Lopatka kompresoru by měla mít návrh, který nejprve byl naplánován na papíře. Nakonec tento návrh přejde do počítače. Tento počítač pomáhá speciálnímu stroji, který řezá tvar lopatky z materiálu. Zatímco stroj pracuje na vytvoření lopatky, pozorně sledují vysokoškolení technici. Ti zajistí, aby byla lopatka vyráběna správně a splňovala všechny požadované směrnice.

Dříve byl výrobní proces kompresních listů náročný a vyžadoval mnoho rukou. Dnes je tento proces díky pomocí sekcí: úžasných strojů schopných provádět velmi sofistikované úkoly, významně rychlejší a jednodušší. Tyto pokročilé stroje, které převážně využívají laserů a dalších sofistikovaných nástrojů, řezají a tvarují kompresní listy s velkou přesností. To je proto, že tyto typy strojů jsou navrženy tak, aby nikdy neřezaly šablonu či cokoli jiného, co jste do nich umístili. To umožňuje dosáhnout jak krátké doby výroby, tak i požadované kvality listů.

Při výrobě kompresních listů je jednou z největších obtíží být přesným a zároveň rychlým. Všechny listy musí být identické, protože pro motor je to velmi důležitá součást, která musí běžet hladce a bez problémů. Na druhé straně musí být proces dostatečně rychlý, aby se dosahovaly úspory a aby si mohl motor dovolit každý. Výrobci na tom pracují prostřednictvím inteligentního softwaru, který monitoruje a reguluje výrobní proces. Tento software zajišťuje, že všechny listy jsou vyrobeny přesně a ve správných rozměrech, což je nutné pro výkon motoru tak, jak by měl být.

Lopatky kompresoru v reaktivních motorech musí být silné a spolehlivé z jasných důvodů bezpečnosti. Lopatky musí být součástmi vysocejšího tlaku, protože motor má mít dostatek síly na to, aby letadlo zdvihl do velkých výšek z úrovně země. Vyrábějí se ze speciálních materiálů, aby nezlomily při vystavení tomuto tlaku, protože každá lopatka musí být velmi silná. Titán: Titán je jedním z nejlepších materiálů používaných, je lehký a pevný. To vše znamená, že lopatky mohou plnit svou práci bez přidání dalšího hmotnostního zatížení našeho letadla. Lopatky také pravidelně procházejí údržbou a inspekční kontrolou, aby se zajistilo, že jsou ve vynikajícím pracovním stavu.

Jsme schopni vyrábět součásti turbín s vysokou přesností a konzistencí pomocí CNC lití, obrábění a kování. Lití nám umožňuje vyrábět díly pomocí výrobního procesu kompresorových lopatek proudových motorů, které jsou pevné a odolné. Kování poskytuje dílům vyšší odolnost a lepší mechanické vlastnosti. Naopak CNC obrábění je extrémně přesné a zaručuje konzistenci každého dílu. Tím se eliminují chyby a výrobky nízké kvality. Náš zkušený technický tým neustále zkoumá technologický pokrok a optimalizaci procesů, aby naše výrobky zůstaly na špičce průmyslové technologie. Zavazujeme se splnit požadavky našich zákazníků na vysokovýkonné součásti turbín neustálým technologickým rozvojem.

Naše společnost nabízí služby na míru a je schopna vyrábět lopatky kompresoru proudových motorů z řady slitin odolných vysokým teplotám podle specifikací zákazníka. Ať už jde o konkrétní rozměry, tvar nebo požadavky na výkon, dokážeme je splnit díky našemu flexibilnímu výrobnímu procesu a nejmodernějším technologiím výroby. Spolupracujeme velmi těsně se svými zákazníky, abychom plně pochopili jejich potřeby i různé scénáře, kterým mohou čelit, a následně jim poskytneme odbornou pomoc a doporučení. Naše široká škála možností zpracování materiálů, zpracovatelských kapacit i specifických požadavků na dané aplikace nám umožňuje uspokojit konkrétní potřeby různých průmyslových odvětví a aplikací. Díky individuálním službám pomáháme našim zákazníkům optimalizovat výkon svých výrobků, snižovat náklady a zvyšovat konkurenceschopnost na trhu.

Naše společnost se zavazuje dodržovat přísné normy kontroly kvality, abychom zaručili nejlepší výkon a spolehlivost každé součásti. Každý krok výrobního procesu je kontrolován z hlediska kvality – od nákupu surovin až po koneční test výrobku. Pravidelně také provádíme audit kvality i úpravy procesů, abychom zajistili trvalé zlepšování kvality výrobků. Naším cílem je získat důvěru našich klientů a dlouhodobě s nimi spolupracovat nabídkou výrobků nejvyšší kvality a stát se vedoucím výrobcem lopatek kompresoru proudových motorů.

Náš kompletní balíček služeb pro zákazníky zahrnuje technickou podporu, poradenství před prodejem a servisní podporu po prodeji, aby naši zákazníci získali co nejlepší možné zážitky. V rámci předprodejního poradenství náš tým odborníků podrobně pochopí potřeby zákazníka a poskytne nejvhodnější návrhy produktů a řešení. Nabízíme technickou podporu od výběru produktů až po jejich instalaci a uvedení do provozu. Tím zajišťujeme, že naši zákazníci mohou bez jakýchkoli problémů používat naše produkty v procesu výroby lopatek kompresoru proudových motorů. Máme dobře vyvinutý systém servisní podpory po prodeji, který nám umožňuje rychle reagovat na dotazy a problémy zákazníků a poskytovat efektivní a okamžitá řešení. Naším cílem je budovat dlouhodobé vztahy se zákazníky a získat jejich důvěru a spokojenost kvalitní službou.