The combustion chamber of turbojet engine has a significant effect on the working condition. It is an important contributor to the high temperature and pressure it generates. Here at O.B.T our engineers are very experienced and specialise in creating combustion chambers to produce a high efficient system for performance of aircraft. We achieve through creative use of advanced materials and advanced manufacturing techniques, and are able to offer durability, fuel efficiency, emissions, design precision, and performance products down to the basic cost needs meeting the expectations of the industry.

As the advanced materials are used in turbojet engine combustion chambers then only its longevity and survivability will be guaranteed. At O.B.T we use state of the art materials such as superalloys and ceramic composites to survive the harsh environment in the combustion chamber. These substances have been designed to withstand the harsh environment of high temperatures, corrosion and thermal stresses for the guaranteed minimum life period. Our production methods consist of machining, 3-D printing and robotic assembly to ensure precision and consistency to all of our products.

Improved fuel efficiency and reduced emissions are key targets in contemporary aeronautics to limit the environmental impact of aeronautic platforms. O.B.T focus on designing better Turbojet Engine combustion chambers to increase the efficiency fuel burning process, delivering more power with less fuel. Since we regulate the air/fuel mixture and combustion process so precisely, we are able to obtain optimum thermal efficiency with minimal emissions. We have certified models that are well equipped to comply with strict environmental laws while providing a responsible choice for the environmentally sensitive operator.

Our methodology of design follows the method of precision engineering of turbojet engine combustion chambers. Our experienced engineers use state of the art computer aided design (CAD) software tools and simulation techniques to optimize the performance of our combustion chambers. By studying the flow of air, dynamics of combustion and transfer of heat, we are able to make the design fine-tuned for optimal power production and life. This level of detail assures our combustion chambers perform very well in any environment that we operate inwith safety of flight and efficient flightoperations.

At O.B.T, we realize that each airline and aircraft manufacturer has specific requests and guidelines to which we can easily adhere. Which is why our turbojet engine combustion chambers are available in these variations, to suit all your requirements. If that customization needs to come in the form of the size, shape or material of the combustion chamber, our team believes it’s a worthwhile approach to our business. We collaborate closely with our customers to make our combustion chambers a perfect fit in their aircraft systems, offering a dependable, efficient solution that complies with industry requirements and regulations.

Our comprehensive customer service includes pre-sales consulting technical support and after-sales services to ensure that customers enjoy the most enjoyable experience Our expert team will assess the needs of customers and offer appropriate product suggestions and solutions We provide technical support starting with the selection of products through installation and commissioning This ensures that our customers are able to enjoy our products without issues For after-sales support we have developed an efficient service system that can respond swiftly to customer issues as well as needs and provide turbojet engine combustion chamber and efficient solutions Our goal is to create long-term relationships and gain customers trust and their satisfaction by providing superior customer service

Our company offers a variety of customized services, and produces turbine components from an array of high-temperature turbojet engine combustion chamber to meet the requirements of our customers. Our flexible production process and advanced technology for processing and our ability to satisfy specific requirements, such as size shape, performance, or shape, allows us to achieve every need. We communicate closely with our customers in order to fully understand their individual requirements and situations and offer expert advice and solutions. We offer a wide range of materials and processing capabilities to meet the specific demands of various industries and applications. Through customized services, we help our customers optimize product performance and efficiency and increase competitiveness in the market.

Our company adheres to strict quality control guidelines to ensure excellent performance and turbojet engine combustion chamber of every component. Quality control is carried out throughout the entire process of production beginning with the purchase of raw materials to the test of the finished product. We also regularly conduct quality audits and adjustments to ensure constant enhancement of the product's quality. Our goal is to win the trust and cooperation of our customers by providing high-quality products and to become an industry leader.

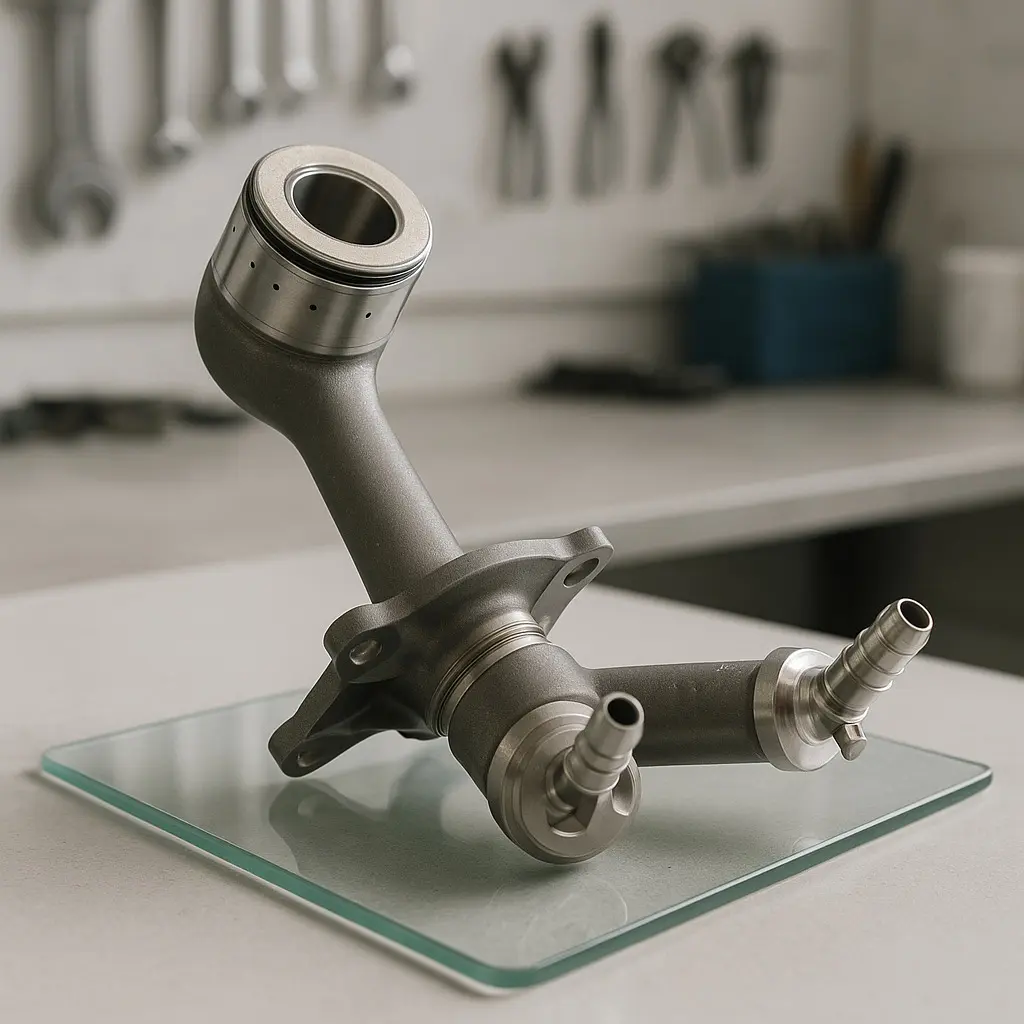

We are able to create turbine components with high accuracy and consistency using CNC casting, machining and forging processes. Casting allows us create parts with turbojet engine combustion chamber, strong and durability. Forging offers parts more durable and superior mechanical property. CNC machining, on the contrary is extremely precise and consistency for each part. This eliminates mistakes and poor quality products. Our experienced technical team is continuously researching technological advances and process optimizations in order to keep our products at the leading edge of industry technology. We're committed to meeting the demands of our customers for high-performance turbine components by the continuous advancement of technology.