Har du nogensinde overvejet, hvad der gør din bilsmags motor køre? Den afgørende del kaldes for kuldekomkammeret. Det er en af de ting, der holder din bil på vej og får den til at bevæge sig effektivt ned ad vejen på en flydende måde. I denne episode vil vi gå dybere ind på, hvad kuldekomkammer faktisk er og hvordan de virker for at holde din bil kørende.

Hvordan slår man dem til, når du starter bilen? Den anden vigtige væske, som også er særlig i definitionen, fordi den letterlig feed bilen med den magt selv, er brændstof - det blander sig sammen med luft inde i ovennævnte kuldekomkammer. Dette blandingsprodukt er hjertet i en motor, dette er, hvad der gør den til at bevæge sig. En lille sprøjte genereres med hjælp fra et lille gadget kendt som en sparkløge, på præcis tidspunkt. Denne sprøjte tændter brændstof og luftblandingen skabende en lille eksplosion. Dette bruges til at skubbe en af disse pistoner nedad. Det kan være skræmmende så meget eksplosion, men ikke bekymre dig, hvem ville ellers have troet, at en eksplosion kunne være så nyttig.

Denne eksplosion skaber energi, der tvinger en komponent, nemlig pisten. Du kan forestille dig pisten som en kraftig arm, der går op og ned i en cylinder. Krumaskellen er det stykke, der roterer, når pisten bevæger sig. Det ligner hjertet i din motor, arbejder for at tage al den energi fra de små eksplosioner og konvertere den til bevægelse. Denne proces bliver igangholdt hele tiden, hvilket resulterer i, at motoren virker og giver styrke, hvilket giver den nødvendige forskydning for at få dit bil kørende fremad.

Brændstofsprøjten er en maskine, der udsender sprøjten i hver af de enkelte tråde i forbrændelsesområdet. Det er godt, fordi det hjælper med at blande brændstoffet ligeligt med luft. Her kommer glødningerne ind i billedet. Det er egentlig det, der skaber sparken, der forårsager, at dette brændstofs- og luftmiks eksploderer. Sidst er ventilerne, som fungerer som porte til at lade luft komme ind og ud af en forbrændelseskammer. Disse anslag sikrer, at der er nok luft, der når til forbrændelseskammeren.

En godt vedligholdt forbrændelseskammer vil føre til, at din bil kører bedre end nogensinde før og bruger brændstof endnu mere effektivt. I de enkleste vendinger vil en god forbrændelseskammer tillade den perfekte mængde brændstof og luft at mødes for en ekstremt kraftig eksplosion. Det betyder, at brændstof og luft vil forbrænde fuldt ud, så du får mere magt til din bil og også bedre forbrug.

Gennem årene har mange dygtige ingeniører kommet på nye ideer og forbedringer til forbreningskammeret. En fremtrædende fremskridt, såvel dengang som i dag, er turboden. En turboden - en enhed, der tvinger mere luft ind i forbreningskammeret. Dette resulterer i færre emissioner, men tillader også, at bilen kan producere endnu mere magt fra sine eksplosioner, da den kan forbrænde mere brændstof. Desuden forbedrer turbodene brændstofsøkonomien ved at gøre bedre brug af benzin, der allerede er i røret.

Variabel venter timing er en anden interessant innovation. Hvad dette smarte system gør, er at åbne og lukke ventilerne når det er nødvendigt, alt efter hvor hurtigt eller langsomt motoren drejer sig og også afhængigt af nuværende belastning. Det kontrollerer effektivt luftforsyningen til forbreningskammeret, hvilket gør driften smooth.

Vores kundeservice er motorforbrændingskammeret og omfatter teknisk assistance, rådgivning før salg og service efter salg for at sikre, at vores kunder får den bedst mulige oplevelse. Vores erfarene team vil gennemgå kundernes behov og tilbyde den mest effektive løsning samt anbefalinger for produktet. Vi leverer teknisk support fra udvælgelsen af produkter til installation og idriftsættelse. Dette garanterer, at vores kunder kan nyde vores produkter uden problemer. Vi har en veludviklet service efter salg, der giver os mulighed for hurtigt at reagere på kundernes henvendelser og problemer samt levere hurtige og tidssvarende løsninger. Vi stræber efter at opbygge langvarige relationer med vores kunder og opnå deres tillid og respekt ved at levere kvalitetsservice.

Vores virksomhed følger strenge standarder for motorforbrændingskammer for at sikre fremragende ydeevne og pålidelighed af hver enkelt komponent. Kvalitetskontrol udføres gennem hele produktionsprocessen – fra indkøb af råmaterialer til test af det færdige produkt. For at sikre, at kvaliteten af vores produkter løbende forbedres, udfører vi regelmæssige revisioner og forbedringer. Vi stræber efter at opnå vores kunders tillid og deres langsigtet partnerskab ved at levere produkter af høj kvalitet.

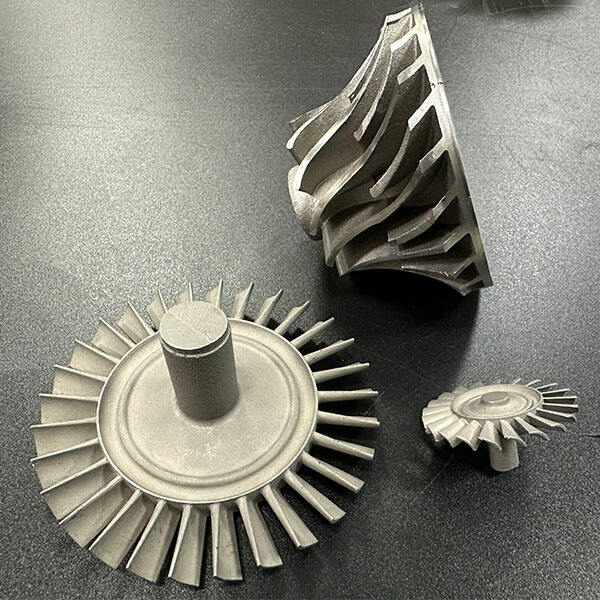

Vores virksomhed er i stand til at fremstille yderst præcise og stabile turbinekomponenter gennem støbning, smedning og CNC-bearbejdning. Støbningsprocessen giver os mulighed for at fremstille forbrændingskamre med komplekse former og høj holdbarhed, mens smedningsprocessen forbedrer de mekaniske egenskaber og forlænger levetiden af komponenterne. CNC-teknologien, derimod, sikrer den højeste præcision og nøjagtighed for hver enkelt komponent, hvilket reducerer risikoen for fremstillingsfejl og derved understandardiserede produkter. Vi har et erfaret teknisk team, der løbende udfører teknologisk innovation og procesforbedring for at sikre, at vores produkter altid er på toppen af branchen, hvad angår teknologi. Vores forpligtelse er at imødekomme vores kunders behov for højtydende komponenter ved løbende at udvikle teknologien.

Vores virksomhed leverer forbrændingskammer til motorer, og vi er i stand til at fremstille turbinekomponenter af mange højtemperatur-aluminiumlegeringer for at opfylde kundernes krav. Vores fleksible produktionsflow og avancerede bearbejdningsteknologi samt vores evne til at imødekomme særlige krav, såsom størrelse og form samt ydeevne, gør det muligt for os at imødekomme alle behov. Vi samarbejder tæt med kunderne for at fuldt ud forstå deres krav og anvendelsesscenarier og giver dem faglig assistance og rådgivning. Vi har et bredt udvalg af materialer og bearbejdningsevner til at imødekomme de særlige krav fra forskellige industrier og anvendelser. Vores kunder kan forbedre deres konkurrenceevne på markedet ved at tilbyde skræddersyede løsninger, der optimerer ydeevnen og reducerer omkostningerne.