For instance, do you realize that airplanes utilize high power and powerful engines? Aerospace engines are called these, and they help the plane take off up high into the sky. An aerospace engine has many different parts that contribute to making the overall system, with every part playing a vital role in keeping it running as desired. If this piece of information teaches us anything, it is the complexity that goes into making an airplane fly through the air.

There is a particularly critical component used in the aerospace engine which is high pressure turbine disc. This may sound like a complex term but it accounts as one of the very important pieces of lubricant required to keep the engine running smooth and efficiently. The airplane would not be able to create the energy required for flying well without this part.

The use of high pressure turbines airline engine disks, they are to make the aircraft work better and more efficiently. In the engine's exhaust, special discs help transform hot gases from burning fuel into energy that moves an airplane forward. This is critical to assure the setting of an airplane.

The discs are manufactured from special materials that can withstand high temperatures and great pressure. As they are meant to spin quite quickly, this allows for the energy produced by hot gases during combustion. This rotating motion is what transforms the energy into mechanical(the physical part) to move/flight the airplane.

Engineers are continually trying to improve high pressure turbine discs, so that they perform even better. They come up with inventive concepts and fresh designs for these core components to be able perform at higher temeratures & pressures without failing. This constant innovation is important in the progression towards better aviation tech.

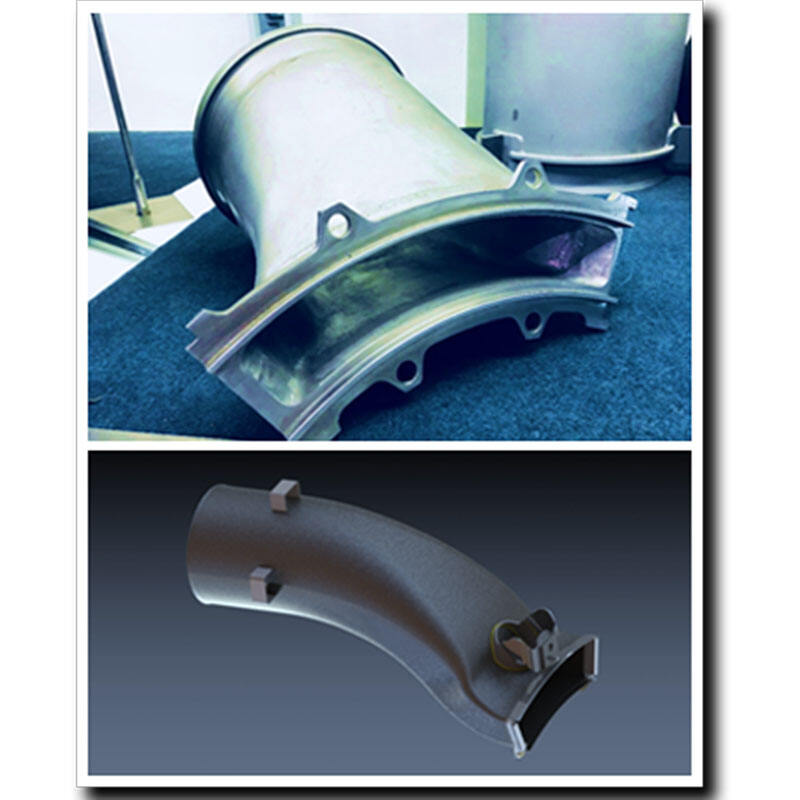

New and innovative manufacturing methods also help engineers enhance the present design of discs. Thanks to such new techniques they are able now to manufacture them in all sorts of different shapes and designs, that can improve the efficiency of these discs. The point of the shape is to make the discs contribute more or less (depending on a number of factors) as needed by the engine overall.

As these high pressure turbine disc predator sun blades continue to improve, it is possible that we may even see engines in the future with greater power output given a similar fuel burn. In the future, some of us could be flying on planes with engines that are quiet and emit less pollution making for a pleasanter flight experience all round.

Our customer support is high pressure turbine disc and includes technical assistance, pre-sales advice and after-sales assistance to ensure our customers have the best possible experience. Our experienced team will review the needs of customers and offer the most effective solution and recommendations for the product. We provide technical support starting with the selection of products to installation and commissioning. This guarantees that our clients are able to enjoy our products without problems. We have a well-developed after-sales service that allows us to react quickly to customer requests and problems and provide quick and timely solutions. We strive to establish long-term relationships with our customers and earn their trust and respect by providing quality service.

Our company adheres to strict quality control guidelines to ensure excellent performance and high pressure turbine disc of every component. Quality control is carried out throughout the entire process of production beginning with the purchase of raw materials to the test of the finished product. We also regularly conduct quality audits and adjustments to ensure constant enhancement of the product's quality. Our goal is to win the trust and cooperation of our customers by providing high-quality products and to become an industry leader.

We are able of producing turbine components with high accuracy and consistency through CNC machining, casting and forging processes. The casting process permits us to create parts with intricate shapes and strong strength, while the process of forging provides parts higher mechanical properties and longer lasting. CNC machining, on the contrary it provides superior precision and consistent quality for every part. This reduces errors and lower quality products. Our skilled technical team is always working on technological innovations and process optimizations in order to high pressure turbine disc that our products remain at cutting-edge of technology in the industry. Our goal is to satisfy the needs of our customers for high-performance parts by constantly advancing technology continuously.

Our company can provide customized services and is able to fabricate turbine components from an array of high-temperature alloys in accordance with the requirements of customers. No matter what high pressure turbine disc, size or performance requirement, we can achieve it with our flexible production process and cutting-edge technology for process. We work closely with clients to comprehend their needs as well as the various scenarios they might encounter and give them professional assistance and suggestions. We have a variety of materials and processing capabilities to meet the unique requirements of different industries and applications. We aid our clients in improving their competitiveness on the market by offering custom-designed services that improve efficiency and lower costs.