Improve compressor efficiency with cutting-edge inlet guide vanes powerandeducation.lendrummullins.com Increase compressor efficiency with our latest inlet guide vanes technology Increased efficiency up to 1.5%ϔ!

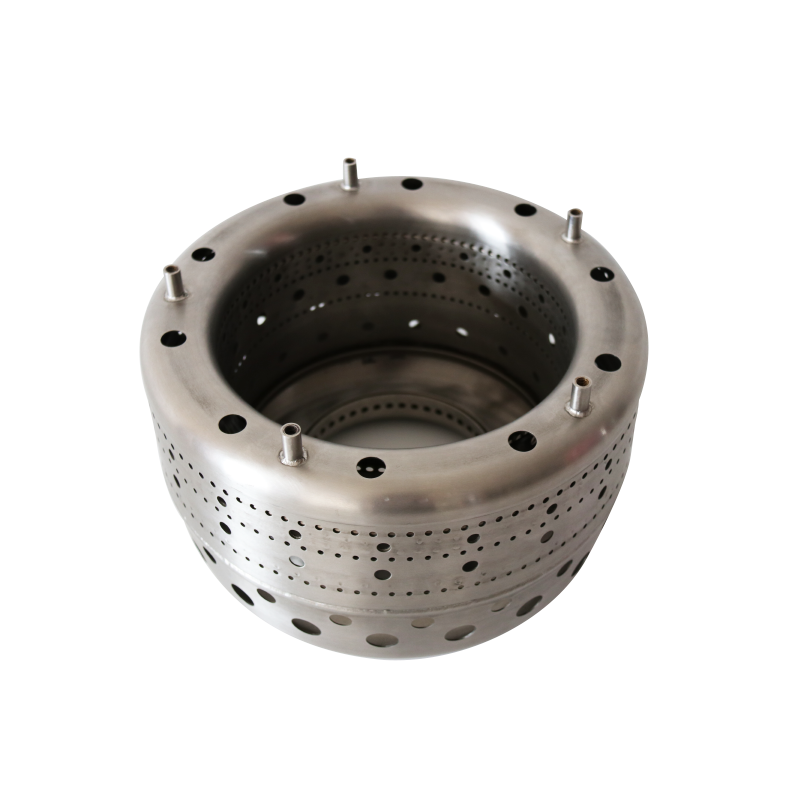

Looking to improve your compressor package efficiency? Say hello to O.B.T's hitech inlet guide vanes! By utilizing our revolutionary technology you can increase performance of your compressor system. These doves are engineered to maximize airflow and efficiency. Here’s how our latest tech can supercharge your system.

Maximize airflow control in your compressor system with O.B.T's top performing guide vanes. The guide vanes are fine-tuned to guarantee a powerful and efficient airflow resulting in the best performances. When you manage the airflow properly, and you’ll enjoy substantial savings on your energy bill, which could help make your system pay for itself over time. Goodbye, wasteful airflow Our cutting-edge guide vanes technology.

When it comes to the quality and long service life of your compressor, O.B.T guide vanes are the answer. We use very high quality materials to make our guide veins and is NOT seen by the eye. Ensure that your equipment is safe and your system continues to run smoothly with our high-quality guide vanes. Rely on O.B.T for guide vanes that are setting new standards in reliability and longevity in your compressor.

Are you more than tired of those regular maintenance problems in your compressor system? Erect plus smart, O.B.T's engineering inlet solutions solve your problems. Our guide nozzles are designed for longer-lasting, silky smooth operation that just won't wear your system down. With minimal friction and the best control of airflow, you can experience a painless procedure and minimum maintenance. Experience how our revolutionary inlet systems change how your compressor system operates!

While the ongoing consumer buying trend is always changing, it’s important to stay ahead of the game in any competitive industry. O.B.T's state-of-the-art compressor inlet guide vanes Engineer the advantage you need to beat the competition. Our advanced technology also raising the bar on compressor efficiency so you can reach ultimate performance and save energy. And with O.B.T's leading guide vanes, you lead the way and let everyone else follow into their future. Why be average when you can be the best with our state of the art products.

We follow compressor inlet guide vanes for quality control to ensure the performance and reliability of every component. The entire process of production is subject to quality control, from the raw material purchase until the final testing of the product. We also regularly conduct quality audits and improvements to ensure continuous improvement of product quality. We are determined to gain the trust of our clients and to maintain their long-term relationship by offering high-quality products.

Our complete customer service package includes technical assistance pre-sales advice and after-sales assistance to ensure that our customers receive the best experience possible At the time of pre-sales our team of experts will be able to understand the needs of the customer in detail and provide the most appropriate product suggestions and solutions We offer technical assistance from the selection of products through installing and commissioning This guarantees that our customers are compressor inlet guide vanes to use our products without any issues We have a well-developed after-sales system that allows us to respond quickly to customer concerns and issues and provide efficient and prompt solutions We aim to build long-term relationships with our clients and earn their trust and satisfaction by providing quality service

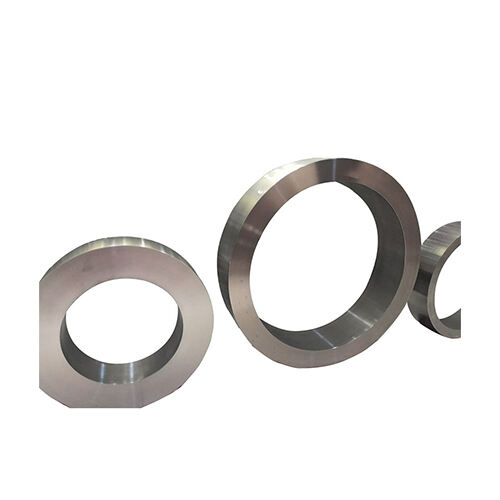

We are able to create turbine components with high accuracy and consistent quality through CNC machining, casting and forging processes. Casting allows us to create parts with complex shapes, high strength and long-lasting. Forging can give parts a more durable and superior mechanical property. CNC compressor inlet guide vanes technology, on other hand, ensures the highest precision and accuracy of each piece, minimizing mistakes and ensuring that the product is of a high standard. Our highly skilled technical team is continuously developing technological advancements and process optimizations in order to keep our products at the cutting-edge of technology in the industry. Our commitment is to meet the needs of our customers for components that are high-performance by developing technology continuously.

Our company offers a variety of custom-designed services and is able to manufacture turbine parts from various high-temperature alloys to meet the requirements of our customers. Our compressor inlet guide vanes along with our advanced process technology and our capability to meet specific requirements, such as size shape, performance, or shape can allow us to meet every need. We work closely with our customers to understand their specific needs and application situations and offer expert technical guidance and solutions. Our wide range of products processing capabilities, processing capabilities, and specific requirements to the application allow us meet the requirements of various industries and application. With our customized services, we assist our customers in optimizing their the performance of their products and reduce costs, and improve market competitiveness.