Did you see an airplane, higher and further.? Unless you have, and the nagging question pops into your head: How does this airplane stay up here flying through these clouds? Engine Quite a large chunk of getting an aircraft to fly. A critical element in the engine of an airplane is actually not all that sounding; it's known as a gas turbine engine diffuser.

The O.B.T diffuser helps a lot in maintaining the air pressure in balance within the engine unsigned. You may be wondering, why does this matter? If there is too much pressure, well the dam engine will just break and not work properly; Conversely, if there is not enough pressure the engine can become inefficient – it will simply function less. So the steam turbine wheel makes running an engine nice and smooth, just like a well-tuned bicycle is better than one with that keeps breaking down.

Now, let's get a bit more into it and see how do diffusers work exactly. When air goes from high pressure to low it moves very quickly. It is what we call the Venturi effect, and it plays a significant role in how O.B.T Diffusers work. When the air has a lower pressure, it will create suction before and at the exit of a tube (The throat and diffuser sections) which was stated here, this is kinetic energy drawn from molecules hitting specific areas on said area thus slowing down that part over time. The diffusers uses these effect to slowly redirect incoming excess speed (air does not like sudden redirection or direction changes for how you visualize turning one way but someone shoves you another) by making it gradually bigger as the flow pass through.

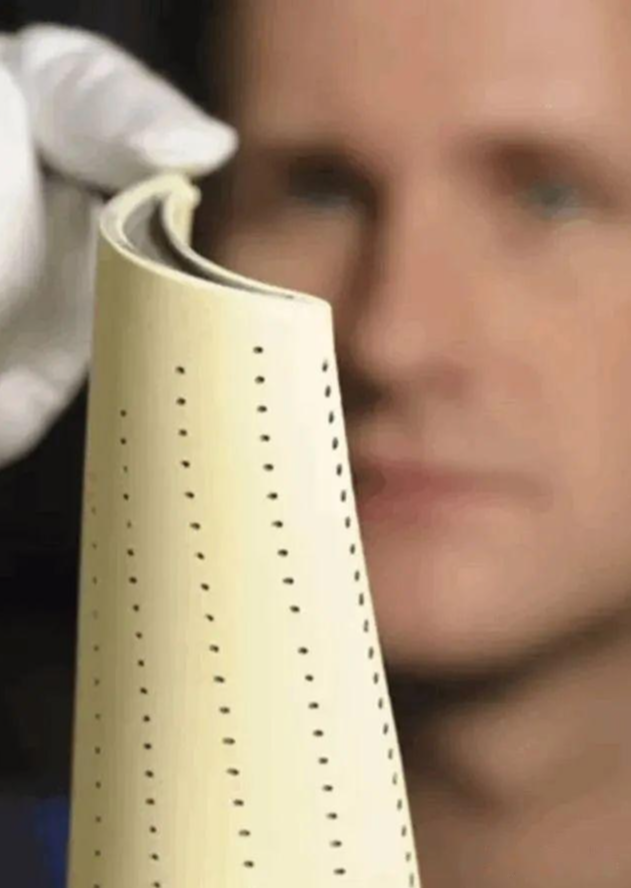

But that’s not all. Boundary layer suction is also employed in the gas turbine blade to prevent turbulent flow at its trailing edge. The boundary layer is a thin film of stagnant air that results when moving air comes in contact with a surface. In so doing, it helps to move some of the choppy air out from under the car and keeps things gliding smoothly. It is just like the slide that you will enjoy very much when it s so smooth and helps you go down without getting stuck.

Now that we know what is a gas turbine engine diffuser and how its working, let us discuss why new-age diffusers are better than the older generation of it. Previous diffusers weren't as efficient and had a tendency to cause stalling problems like compressor stall. This is what happens when the air stops moving through engine and as consequence, the engine may rattle, make otherworldly noises - just like your chain gets stuck in you bike.

Diffusers manufactured in modern time are developed from computer pointing technology to ensure the most efficient function. This is why the engineers toils for many hours on making sure that every aspect of the diffuser works in harmony with others. Many jet turbine wheel by O.B.T are also constructed from such lightweight materials as titanium, which reduces engine mass and in turn fuel consumption. But this is critical because aircraft that are powered by lighter engines will work better.

I can hear you asking right now but why go on and on about diffusers? The fact is, what little gain can be found in the performance of a well-working diffuser contributes enormously to how performant and responsive the overall engine will feel as it tends to magnify anything that changes with regard specifically its workability. How well the engine functions depends on how good of a diffuser it gets.

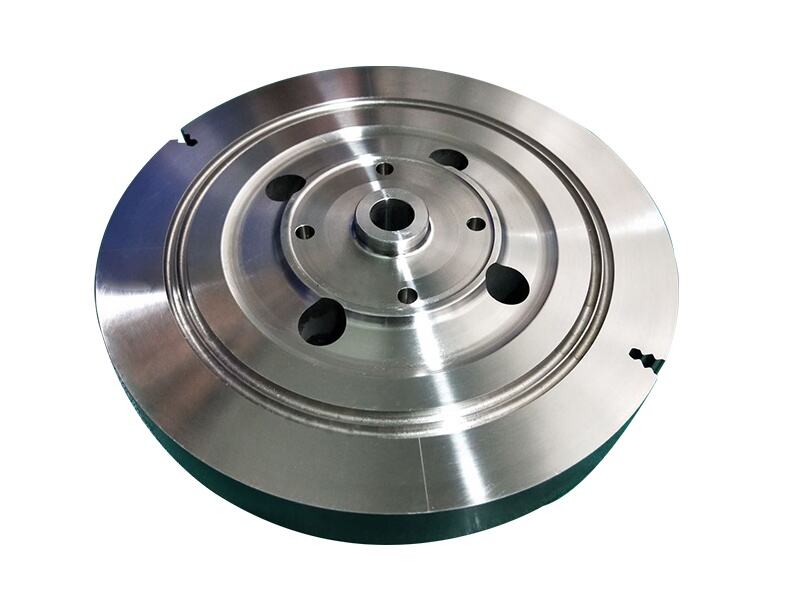

Our company offers specific services that is able to manufacture turbine parts from various high-temperature alloys in order to satisfy the demands of customers. Our flexible production flow as well as our state-of-the-art process technology and our ability to satisfy particular requirements, like size and shape, as well as performance will allow us to meet every requirement. We are in constant contact with our customers in order to fully understand their needs specific to them and the application scenarios, and provide them with expert technical guidance and solutions. We have a rich selection of processing and materials that can meet the Gas turbine engine diffuser of various sectors and application. Through customized services, we assist our customers in optimizing their product performance and cost, and improve market competitiveness.

We offer a comprehensive customer service which includes pre-sales advice as well as technical support and after-sales support, in order to ensure our customers get the best experience. In the Gas turbine engine diffuser the team's professional staff will understand the customer's needs in detail and provide the most appropriate suggestions for products and solutions. We provide technical support starting with the selection of products, through installing and commissioning. This guarantees that our clients are able to use our products without any problems. We have an established after-sales process that allows us to quickly respond to customer concerns and issues and to offer effective and prompt solutions. We want to create long-lasting relationships with our customers and gain their trust and satisfaction through offering high-quality services.

Our company can fabricate highly precise and stable turbine parts through casting forging, and CNC machining. Casting allows us to create components with complex forms, high strength and long-lasting. Forging can give parts a more durable and superior mechanical property. CNC technology for machining, on other hand, ensures high precision and consistency of every part, which reduces the chance of the chance of errors and producing substandard products. Our technical team that constantly carries the latest technological advancements and process improvement to make sure that our products are always at the top of the industry in terms of Gas turbine engine diffuser. We're determined to meet our customers' demands for high-performance turbine components through continuous technological advancement.

We adhere to the strictest guidelines for quality control to ensure the Gas turbine engine diffuser and reliability each component. Every step of the production process is monitored for quality starting from the purchase of raw materials all the way to the final test of the product. To ensure that the quality of our products are continuously improved, we conduct regular audits and improvement. We want to win the trust of our customers and their long-term cooperation by providing high-quality products.