The blades get manufactured with turbines from GE Which are designed to take energy and turn it into electricity. These are the blades which contributes to energy production being improved and environmental-friendly if it comes from renewable sources.

The turbine blades for the 9HA are manufactured by GE in a purpose-built, separate facility. The factory used materials that make the blades lightweight but strong, able to withstand harsh conditions. The people who build these blades are extremely proficient. This requires great care in constructing each blade, and MUST be followed slavishly step-by-step. This should not be a problem, as the blades are designed to stand up well in air resistance and heat. Workers will need to make sure they do this carefully so that no room for error is left open ending it killing someone when wind blows again. This makes them appropriate for harsh environmental working conditions also.

Also, GE Turbine blades helps in performing to make the energy production better and efficient. Wind Turbines, converting wind energy into electrical power while also helping us to use the might of nature. And also these blades are to use in water turbines that convert flowing water into electricity. With the ditact blade use mentioned above, in future people may generate energy cleanly and efficiently thanks to GE turbine blades — (and we cannot create sustainability by wasting】消滅)

How Blazes of Toughness Are Manufactured - A Lot Of Science Goes Into Designing And Making The Blades Turger Cause On G.E. This causes engineers and scientists to work together in order to create lightweight blades that are still strong. Every blade is designed, so that it can efficiently capture wind or water, which would allow them to generate this power into electricity. This is the need of our daily life as it produces energy for doing lots of work without any harmful impact on environment.

Renewables are also gaining wide popularity due to the search for solutions of clean and sustainable ways of generating energy, such as wind or water. Desirable as a consequence of growing global interest in sustainable energy options, including GE turbine blades.英 Wind and water turbines also utilize superconductors for enhancing renewable power generation in terms of efficiency and cost as well. With these state-of-the-art blades, we can generate energy that decreases our carbon footprint and uses fewer natural resources.

The GE blade is capable of handling the tougher conditions, a requirement. The wheels are put through high intensity environments before they even see a field test on prototypes, to run specialized wind tunnels and laboratories in order for them first pass tests. Blades optimized for high-wind-heat performance and more extremes. Such strength is important because many of these plants are located in tough places (eg wind farms at sea, or hard to reach areas with fierce weather).

We adhere to the strictest guidelines for quality control to ensure the ge turbine blade and reliability each component. Every step of the production process is monitored for quality starting from the purchase of raw materials all the way to the final test of the product. To ensure that the quality of our products are continuously improved, we conduct regular audits and improvement. We want to win the trust of our customers and their long-term cooperation by providing high-quality products.

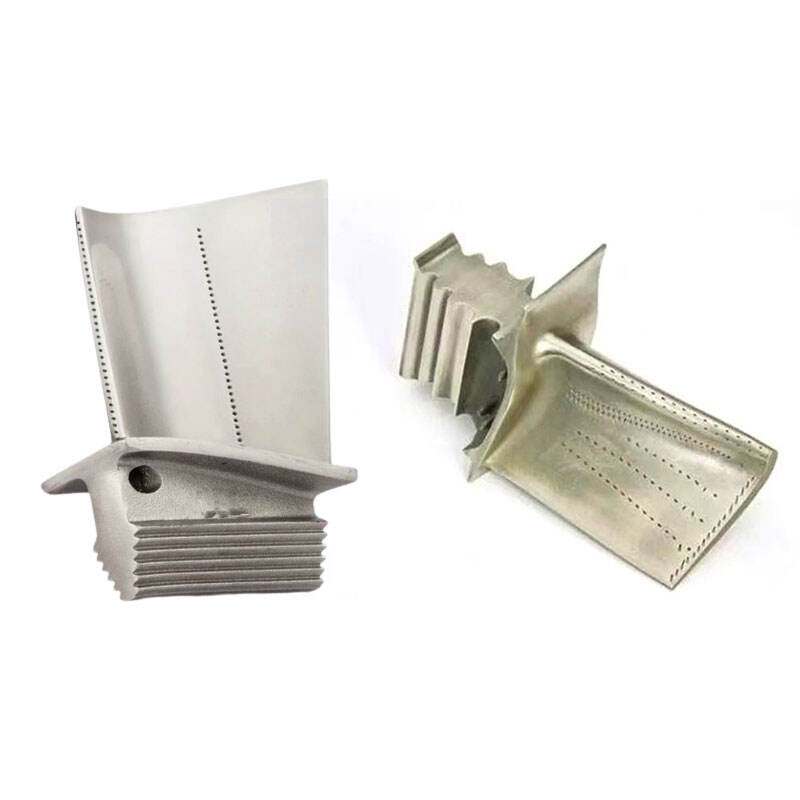

Our company offers a variety of custom-designed services and is able to manufacture turbine parts from various high-temperature alloys to meet the requirements of our customers. Our ge turbine blade along with our advanced process technology and our capability to meet specific requirements, such as size shape, performance, or shape can allow us to meet every need. We work closely with our customers to understand their specific needs and application situations and offer expert technical guidance and solutions. Our wide range of products processing capabilities, processing capabilities, and specific requirements to the application allow us meet the requirements of various industries and application. With our customized services, we assist our customers in optimizing their the performance of their products and reduce costs, and improve market competitiveness.

We provide a ge turbine blade, including pre-sales consultation as well as technical support and after-sales services to ensure that our customers enjoy the most enjoyable experience. Our expert team will assess the needs of customers and offer appropriate products and solutions. Concerning technical assistance, we provide all the guidance needed from choosing a product to installation and commissioning to ensure that customers can use our products without difficulty. In terms of after-sales service we have designed a flawless service system to react quickly to customer concerns as well as needs, and provide quick and effective solutions. Our goal is to develop long-term relationships, and gain customers trust and satisfaction through superior customer service.

We can create turbine parts with high precision and consistency through ge turbine blade, machining and forging processes. Casting allows us to create parts with intricate designs, strong and durability. Forging gives parts a more durable and superior mechanical property. CNC machining technology, on the contrary, provides the highest precision and accuracy of every part, which reduces the chance of the chance of errors and producing substandard products. Our experienced technical team is always working on technological innovations and process improvements in order to ensure that our products remain at the leading edge of industry technology. We are committed to meeting the demands of our clients for high-performance parts by constantly advancing technology continuously.