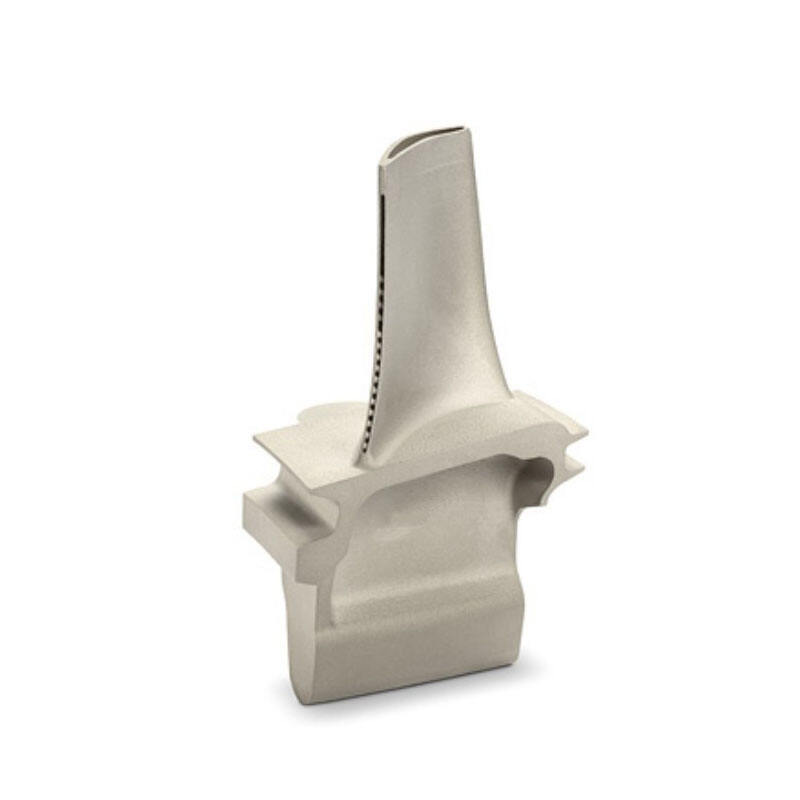

The efficiency of gas turbines depends largely on its turbine blades. These blades experience extreme temperature, corrosive and working stress conditions during usage. For increased efficiency and lifetime of gas turbine blade, we supply gas-tight coatings designed for high temperatures + add-on coatings that are highly protective and offer top performance. The coatings are able to survive under the high temperature and corrosion environments in the hot section of a gas turbine and are able to perform effectively over lengthier service lives.

Gas turbine blades in particular provide demanding requirements given the high temperature and pressure experienced during use. Unprotected, these blades can wear out and reduce performance, or in the worst case become a safety issue. O.B.T's hard coatings for steam turbine blade are developed to offer durable protection from corrosion, oxidation and wearing. These coatings can extend equipment life and maintain reliable performance over time.

In the complex world of industrial production, obtaining the maximum level of energy generation is critical for maintaining competitiveness. Gas turbines are frequently used to produce power because they are efficient and reliable. Use O.B.T's industry-leading high-temperature coatings of gas turbine blades and you can increase energy output and maximize the efficiency of your machinery. These finishes contribute to the minimization of heat loss, to a decrease of friction, and thus provide better efficiency at your gas turbine system.

Both high quality material features and precise processor applications are required to reach a superior performance in industrial application. The midland coating company provides specially applied coatings for gas turbine blade casting – to the very highest standards of quality and duty. Our licensed professionals have the expertise that allows each coating applied to do so with the precision and care that it deserves, increasing their efficiency and earning potential. You can rely on the gas turbine blades with O.B.T

Cost savings are now a leading objective for industrial manufacturers in today's challenging market. Choosing superior coatings can add up to less maintenance, less downtime, and longer component life for your gas turbine blades. The durable coatings are engineered to ensure outstanding protection and performance, so you can advert expensive investment with your gas turbine system. Selecting us as your preferred coating partner leaves nothing to chance, your equipment is always safe and running at its best.

Our customer support is comprehensive and includes technical assistance, High temperature coatings for gas turbine blades and after-sales assistance to ensure that our customers get the best possible experience. Our team of experts will evaluate the requirements of the customer and offer appropriate product solutions and suggestions. We provide technical support throughout the entire process, from choosing products, to the installation and commissioning. This guarantees that our customers can make use of our products with no issues. We have developed an after-sales service that allows us to quickly respond to customer requests and problems and provide efficient and timely solutions. Our goal is to establish lasting relationships with our customers and gain their confidence and satisfaction with quality customer service.

Our company follows strict High temperature coatings for gas turbine blades standards in order to ensure excellent performance and dependability of each component. Quality control is conducted throughout the entire production process beginning with the purchase of raw materials through the test of the finished product. To ensure that the quality of our products is continuously improved, we perform regular audits and improvements. We strive to earn the trust of our clients and their long-term partnership by providing products of high-quality.

Our company provides High temperature coatings for gas turbine blades and can make turbine components in many different high temperature alloys according to the requirements of customers. Whatever the size, shape, or performance requirement, we are able to meet it using our flexible production processes as well as our advanced processes. We collaborate closely with our customers to comprehend their needs and applications scenarios and then give them professional assistance and suggestions. We have a broad range of processing and materials to meet the unique requirements of different sectors and application. We help our clients improve their competitiveness in the marketplace by offering custom-designed services that improve performance and reduce costs.

Our company has the ability to produce highly accurate and consistent turbine components by using casting, forging and CNC High temperature coatings for gas turbine blades. The casting process permits us to produce parts with complex shapes and high strength, whereas the forging process gives the parts better mechanical properties and longer lasting. CNC machine technology, on the contrary, guarantees an extremely high level of precision and consistency in each component, thus reducing the risk of errors and substandard products. Our skilled technical team is always striving to improve technological innovation and process improvements in order to ensure our products are at the cutting-edge of technology in the industry. We're committed to meeting our customers' needs for turbine components that are high-performance through constant technological advancement.