There have been significant changes in the design of jet turbine blades over time, and they keep improving. In earlier times, each and every blade was crafted with the greatest care by hand over a needlessly long amount of time. Now, the new machines and modern techniques have actually started enabling designing engineers to manufacture O.B.T jet turbine blades hundreds of times more faster and effectively.

A very cool way to do so that has been developed is called 3D printing. So, you might use a special type of printer to build up objects in three dimensions — things that used to be incredibly difficult and expensive (or impossible) for us humans. Engineers can design even more detailed and intricate shapes using 3D printing to enhance the performance of the blades. This is an impressive technique fascilitating engineers develop stronger and more efficient O.B.T Turbine Blade that are subjected to harsh conditions within an engine.

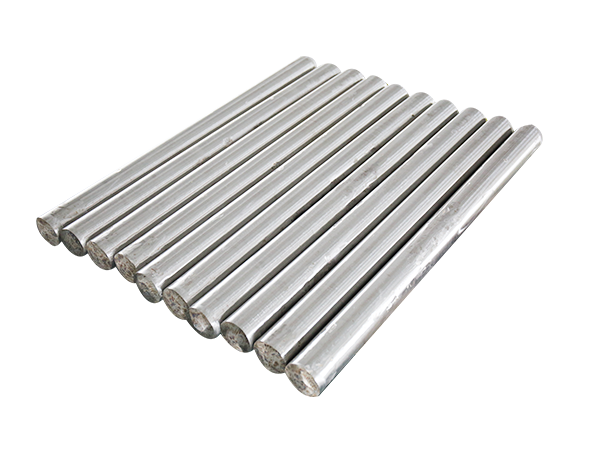

Engineers need different materials that can resist both strong and efficient in order to construct this special blade because the environmental conditions are extreme. These can be titanium, nickel and ceramic composites. Not only are these materials lightweight (critical) but they're also very strong, meaning that it can cope with the high temperatures and pressures found inside a jet engine.

Not only do they have to be built well, but engineers must also use computers to design the blades for various temperature and other conditions. They digitally prototype the blades. This helps engineers to see and modify the design before creating physical prototypes. In this way, they are able to test out a range of ideas and iterate quickly. This O.B.T Turbine Accessories does not only save a lot of time and money but also gives them the guarantee that whatever final product they offer is much superior to anything else out there.

Jet turbine blades are a key component that need to be designed with two objectives in mind: high efficiency and second the performance. Efficiency means getting the most out of motorcycle's engine while at the same time using only as much fuel needed. Performance, though is an entirely more serious question and really about can the blades do what they have to do inside a O.B.T jet engine at high heat loads, in terms of pressure etc?

A good strategy to make the process efficient is building turbine blades in fewer but longer curves called airfoils. The special shape of the blades that generate lift is called an airfoil. Engineers can achieve that simply by making these airfoils a longer distance, and increase not only the lift but also reduce drag. That jet engine blade means the engine needs less fuel to provide a certain level of power output, and that benefits both the environment as well as aircraft performance.

Computer simulations and wind tunnels allow engineers to test how air flows around various blade shapes. These devices help them equate how things are flowing, the pressure that is being exerted and especially if they need to account for any turbulence. With a self-learning algorithm comparing different configurations against one another in an iterative cycle, the team can hone blade designs to find what jet engine turbine blade design works best.

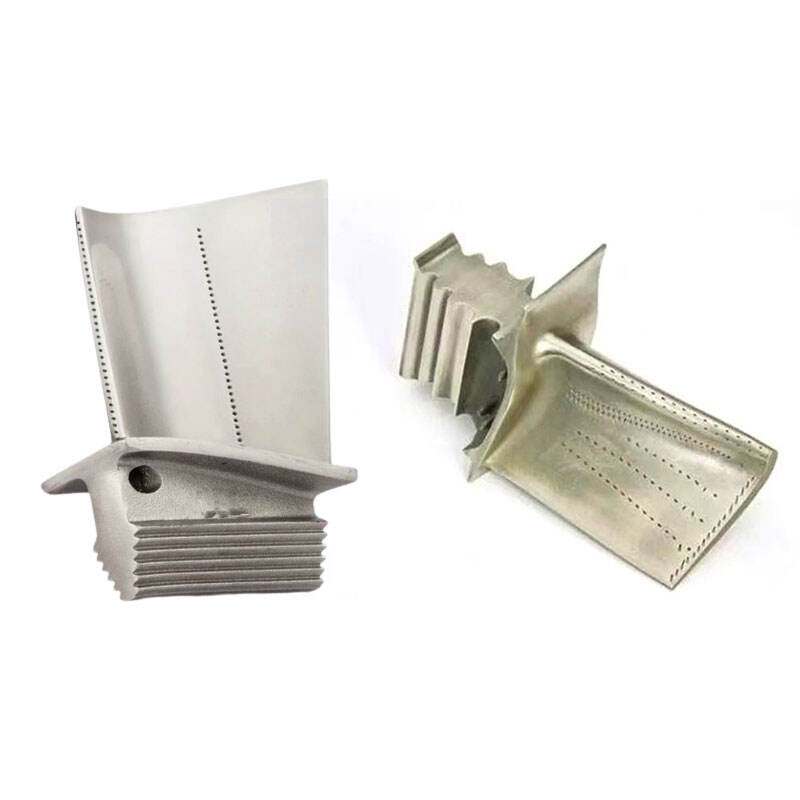

We can create turbine parts with high precision and consistency through Jet turbine blade design, machining and forging processes. Casting allows us to create parts with intricate designs, strong and durability. Forging gives parts a more durable and superior mechanical property. CNC machining technology, on the contrary, provides the highest precision and accuracy of every part, which reduces the chance of the chance of errors and producing substandard products. Our experienced technical team is always working on technological innovations and process improvements in order to ensure that our products remain at the leading edge of industry technology. We are committed to meeting the demands of our clients for high-performance parts by constantly advancing technology continuously.

Our comprehensive customer service includes pre-sales consulting technical support and after-sales services to ensure that customers enjoy the most enjoyable experience Our expert team will assess the needs of customers and offer appropriate product suggestions and solutions We provide technical support starting with the selection of products through installation and commissioning This ensures that our customers are able to enjoy our products without issues For after-sales support we have developed an efficient service system that can respond swiftly to customer issues as well as needs and provide Jet turbine blade design and efficient solutions Our goal is to create long-term relationships and gain customers trust and their satisfaction by providing superior customer service

We follow Jet turbine blade design for quality control to ensure the performance and reliability of every component. The entire process of production is subject to quality control, from the raw material purchase until the final testing of the product. We also regularly conduct quality audits and improvements to ensure continuous improvement of product quality. We are determined to gain the trust of our clients and to maintain their long-term relationship by offering high-quality products.

Our company provides Jet turbine blade design and can make turbine components in many different high temperature alloys according to the requirements of customers. Whatever the size, shape, or performance requirement, we are able to meet it using our flexible production processes as well as our advanced processes. We collaborate closely with our customers to comprehend their needs and applications scenarios and then give them professional assistance and suggestions. We have a broad range of processing and materials to meet the unique requirements of different sectors and application. We help our clients improve their competitiveness in the marketplace by offering custom-designed services that improve performance and reduce costs.