Unparalleled Strength and Efficiency for Monocrystalline Turbine Blades

For wind energy generation, the O.B.T supplies the high-quality single crystal blade with the best technology with the best durability and efficiency. These blades are built for the toughest weather and offer reliable performance for wind energy plants on a global scale. So which design points have secured our position as the preferred supplier of steam turbine blade for the wind energy market?

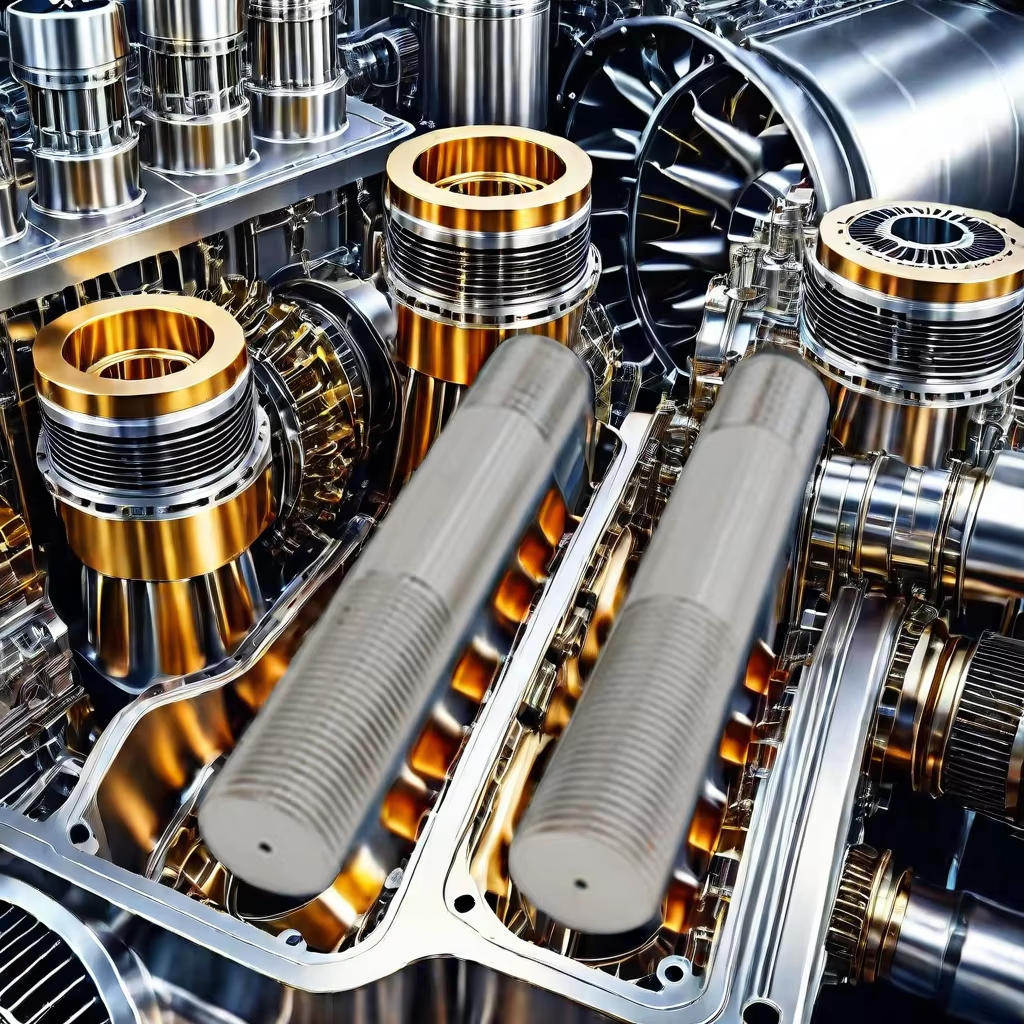

O.B.T’s monocrystalline turbine blades are produced from high grade material to provide outstanding performance in power generation from wind. High-quality components ensure the long-term durability and performance of the blades as a trusted option for your renewable energy projects. With our dedication of top material quality, these aircraft engine turbine blades will last and deliver better results for a very long time to come.

We pride ourselves on being able to integrate the latest technology in both design and manufacture of monocrystalline turbine blades. Capable of withstanding the endless pounding they would take in wind mills these blades offer unparalleled strength and durability. Thanks to recent developments in the industry, we offers turbine blades which are powerful, robust, and above all capable to convert wind energy in electricity in a much more efficient way.

Sustainable and Reliable - One of the major advantages of monocrystalline turbine blades is their reliability for sustainable energy projects. These blades, built to minimize ecological effects, are to be relied on as a source of wind power. By selecting turbine blades, clients can do their part towards the global drive in cutting back on carbon emissions and sustaining clean energy generation.

Amid the sea of monocrystalline turbine blade technology on offer, O.B.T is unparalleled in terms of performance and value. Finally, we are ahead over other turbine blades on the market with its use of top-quality materials, innovative technology and eco-friendly design. We are dedicated to providing world-class products that are excellent value for money products and performance for wind energy generation. With our dedication to quality, customers can be assured that they are purchasing only the best cnc machining turbine blades available for their renewable energy projects.

Our customer support is comprehensive and includes technical assistance, Monocrystalline turbine blade and after-sales assistance to ensure that our customers get the best possible experience. Our team of experts will evaluate the requirements of the customer and offer appropriate product solutions and suggestions. We provide technical support throughout the entire process, from choosing products, to the installation and commissioning. This guarantees that our customers can make use of our products with no issues. We have developed an after-sales service that allows us to quickly respond to customer requests and problems and provide efficient and timely solutions. Our goal is to establish lasting relationships with our customers and gain their confidence and satisfaction with quality customer service.

Our company offers customized services, and can produce turbine components from an array of Monocrystalline turbine blade metals to meet the needs of customers. Our flexible production flow, advanced process technology, and our capacity to meet particular requirements, like size shape, performance, or shape can allow us to meet any requirement. We work closely with our clients to comprehend their needs specific to them and the application scenarios and provide professional advice and solutions. Our diverse selection of materials, processing capabilities and application-specific requirements allow us to meet the needs of a variety of industries and. With customized services, we help our customers optimize product performance and cost as well as increase market competitiveness.

Our company is able to fabricate highly precise and stable turbine components through casting, forging and CNC machine processes. The casting process permits us to Monocrystalline turbine blade with complex shapes and high durability, while the forging process gives the parts better mechanical properties and longer lasting. CNC cutting-edge technology, on contrary, provides the highest precision and accuracy of every part, which reduces the chance of manufacturing errors and resulting in substandard products. We have an experienced technical team who continuously carry out technological innovation and process improvement to make sure that our products are always at the top of the industry in terms of technology. Our commitment is to meet the needs of our customers for components that are high-performance by developing technology continually.

Our company is committed to strict quality control guidelines to ensure the highest quality and reliability of every component Quality control is conducted throughout the entire manufacturing process from the purchase of Monocrystalline turbine blade to the test of the finished product We also perform regular quality audits and improvements to ensure continuous improvement in the quality of our products Our aim is to earn the trust and long-term cooperation of our clients by offering quality products that are of the highest standard and to be a leader in the industry