Steam turbine impeller- it is an important part of a power generating machine. It does this through representative of steam and keeps the wheel turn on when stream courses over it. This spinning motion is what generates power, which can then be used to drive equipment and other devices.

The impeller consists of a number of different parts which all interact with each another. The northeast is the hub and This is a crucial part because without O.B.T turbine blade the rest of steam turbine becomes disconnected with impeller. The hub is what connects the impeller, and without that neither of them are able to do their job. The ones with blades that extend from the hub. This is curved blades and they are designed to get the energy out of steam in order to make motion. That is the motion that produces energy, which we want.

The Power of Steam Turbine Impellers is All in the Movement Steam enters the turbine and strikes the blades on an impeller. This makes the blades are spinning very fast As the wheel spins, it generates energy which can be used to operate various devices including generators or engines. O.B.T second stage turbine blade is so crucial to us, because it helps generate electricity and other type of energy from steam.

Crude as well: ever thought about how the shape of an impeller alters a turbine's efficiency? They spend much of their time examining the dimensions and configuration of blades, since these features could significantly increase or reduce output energy generation. For a steam turbine, if the blades are too large or small in capacity they will not be able to capture all of that energy well. This O.B.T single crystal turbine blade means engineers must very carefully design the blades to ensure they function as well s potential.

Maintaining steam turbine impellers is very important when it comes to keeping the running well. When the impeller is not maintained, turbine blade single crystal can be damaged or dirty and that unbalance causes abnormalities in your pump. This makes it more difficult for the impeller to create power from this. Preventative Maintenance Ideally, you should clean and inspect the impeller every so often to avoid this. This maintenance ensures the turbine can keep producing power efficiently.

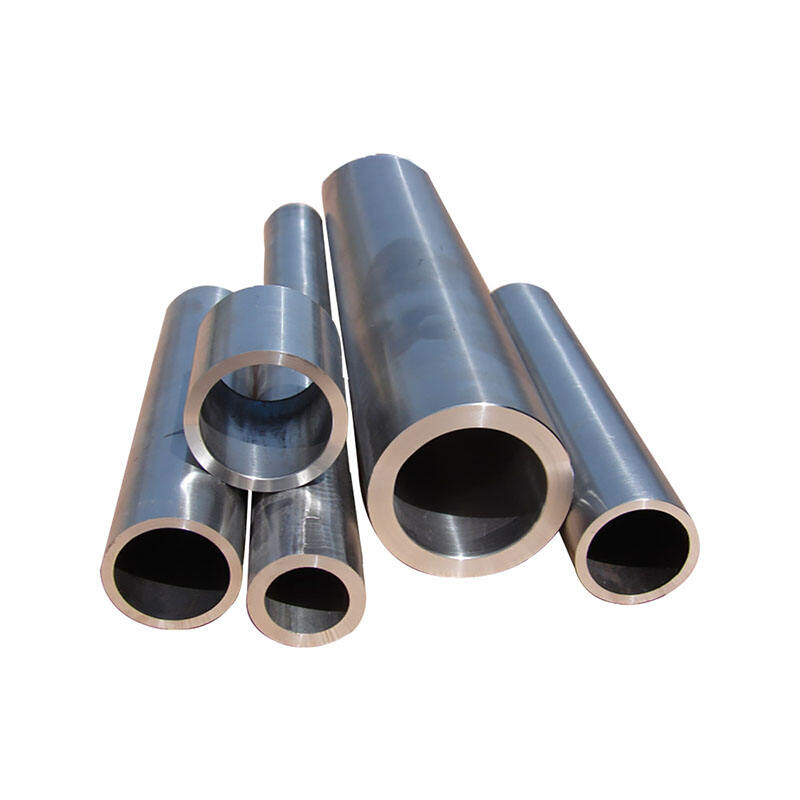

Advances in technology have been driving increased manufacturing performance for steam turbine impellers over the past few years. Many of these newer impellers have blades that are manufactured from more exotic materials, and as a result withstand higher temperatures & pressures than the designs originally fielded. Which allows turbine blade jet engine to produce even more energy before any damage occurs. Consequently those advancements are leading to more, better and stronger machines.

Our complete customer service package includes pre-sales consultation technical support and after-sales assistance to ensure our customers have the best possible experience When it comes to the pre-sales phase our experienced team will understand the customer's needs in detail and provide the most suitable suggestions and solutions In terms of technical support we offer full guidance from product selection until installation and commissioning to ensure that our customers use our products efficiently When it comes to after-sales service we have developed an Steam turbine impeller service system that can respond swiftly to customer issues as well as needs and provide quick and effective solutions We want to create long-lasting relationships with our customers and gain their trust and appreciation by offering high-quality services

We follow Steam turbine impeller for quality control to ensure the performance and reliability of every component. The entire process of production is subject to quality control, from the raw material purchase until the final testing of the product. We also regularly conduct quality audits and improvements to ensure continuous improvement of product quality. We are determined to gain the trust of our clients and to maintain their long-term relationship by offering high-quality products.

Our company offers customized services, and can produce turbine components from an array of Steam turbine impeller metals to meet the needs of customers. Our flexible production flow, advanced process technology, and our capacity to meet particular requirements, like size shape, performance, or shape can allow us to meet any requirement. We work closely with our clients to comprehend their needs specific to them and the application scenarios and provide professional advice and solutions. Our diverse selection of materials, processing capabilities and application-specific requirements allow us to meet the needs of a variety of industries and. With customized services, we help our customers optimize product performance and cost as well as increase market competitiveness.

Our company has the ability to create highly precise and reliable turbine parts through casting Steam turbine impeller, and CNC machining processes. Casting allows us create components with complex designs, strong and long-lasting. Forging provides parts with a better mechanical quality and longer durability. CNC machining, on the contrary offers high precision and consistency for every component. This reduces errors and inferior products. Our technical staff is constantly developing technological advancements and process improvements to ensure our products are at the forefront of industry technology. We're committed to meeting our customers' demands for high-performance turbine components by continual technological advancement.