Increase life of hot turbine blades with the aid of TBCs

The turbine blades are a very important part of turbine operation, whether the turbine is being used in a power plant or an aircraft engine. The above blades are used at high temperatures and may experience wear. To address this issue and extend the life of Turbine Blade, O.B.T has developed the most advanced thermal barrier coating technology. By using this kind of advanced coating for the blades, we are able to shield the blade to be damaged from the high temperature to have a longer life to keep the high performance pattern.

TBT coating combined with the use for the turbine blades equipped with the TBT-Blade under these conditions. One of the most important merits of using high quality thermal barrier coatings for turbine blade is a significant improvement of their efficiency. The cooler the gas turbine blade remain, the hotter the turbines can run while still generating the same amount of power.

The resistance to high temperature is very important for the turbine blades, since they are subjected to an extremely high exposure to heat at work. Without adequate protection, these blades can deteriorate fast, resulting in expensive maintenance and repairs. O.B.T's state-of-the-art thermal barrier coatings stand guard, shielding blades in the world's most extreme environments. With advanced technology, our steam turbine blade can sustain themselves despite extreme heat and will be durable in terms of both strength and life.

When your business is turbine performance, details count. Having robust and efficient Thermal Barrier Coatings (TBCs) can contribute greatly to the ability of a turbine to survive long term in service. The company's coatings are specifically engineered to ensure turbine blades achieve peak operational performance, even under severe conditions. With our history of successful applications of coatings, we put more life into turbine equipment, more value into service for turbine operators, and ultimately, more performance into turbines and less turbine downtime.

In the dynamic setting of industrial manufacturing, creativity is a must to keep ahead of the pack. O.B.T’s innovative thermal barrier coating offerings are at the leading edge of turbine technology with best-in-class protection and performance gains. Through enhanced films we assist our customers´ turbines to be operated even more efficient and reliable. O.B.T’s dedication to quality and excellence means that turbine operators can rely on us to provide the best coating products available to help them maximize performance and achieve their goals.

Our company provides specific services that is able to manufacture turbine parts from an array of high-temperature metals to meet customer needs. If it's a particular shape, size or performance requirement, we are able to meet it using our flexible production process and the latest process technology. We stay in close contact with our clients to comprehend their individual requirements and scenarios, and provide them with expert technical guidance and solutions. We have a broad range of materials and processing capabilities to meet the unique needs of various industries and applications. Our clients can improve their Thermal barrier coating for turbine blades by providing specific services that maximize performance and reduce costs.

Our company adheres to strict quality control guidelines to ensure excellent performance and Thermal barrier coating for turbine blades of every component. Quality control is carried out throughout the entire process of production beginning with the purchase of raw materials to the test of the finished product. We also regularly conduct quality audits and adjustments to ensure constant enhancement of the product's quality. Our goal is to win the trust and cooperation of our customers by providing high-quality products and to become an industry leader.

Our complete customer service package includes pre-sales consultation technical support and after-sales assistance to ensure our customers have the best possible experience When it comes to the pre-sales phase our experienced team will understand the customer's needs in detail and provide the most suitable suggestions and solutions In terms of technical support we offer full guidance from product selection until installation and commissioning to ensure that our customers use our products efficiently When it comes to after-sales service we have developed an Thermal barrier coating for turbine blades service system that can respond swiftly to customer issues as well as needs and provide quick and effective solutions We want to create long-lasting relationships with our customers and gain their trust and appreciation by offering high-quality services

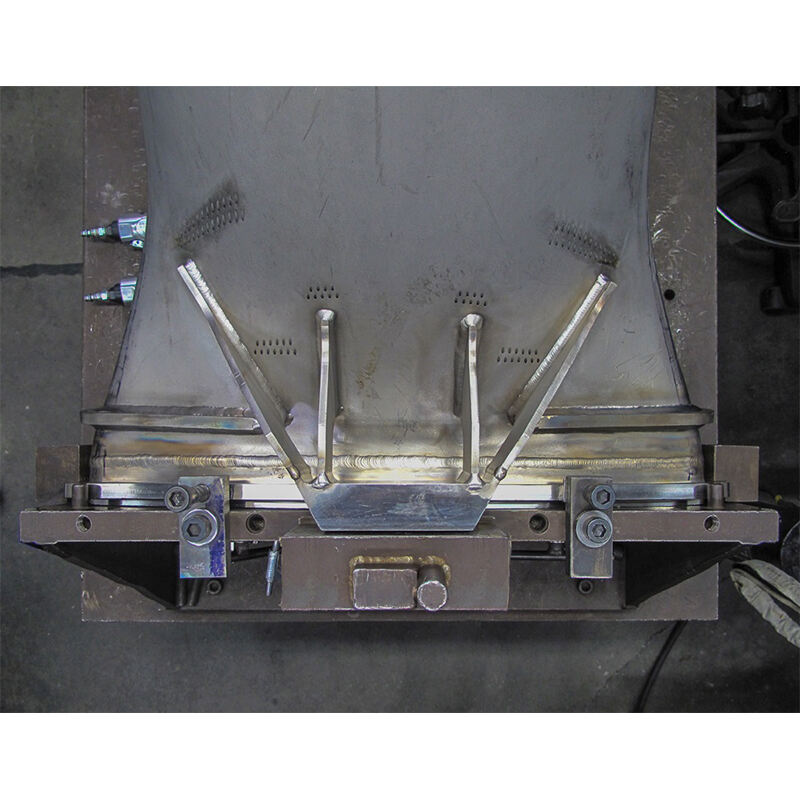

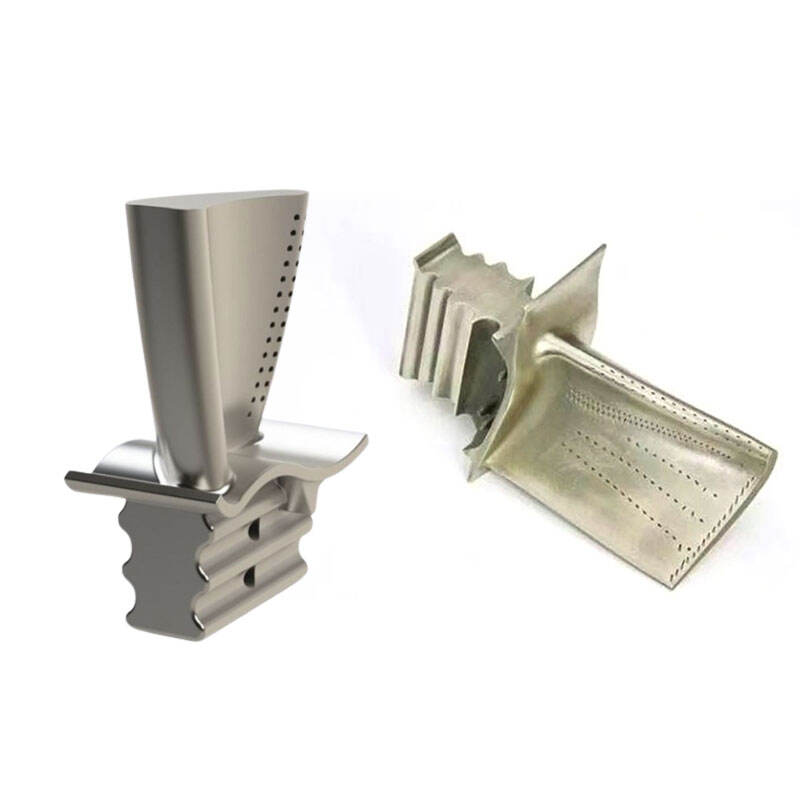

Our company is able to fabricate highly precise and stable turbine components through casting, forging and CNC machine processes. The casting process permits us to Thermal barrier coating for turbine blades with complex shapes and high durability, while the forging process gives the parts better mechanical properties and longer lasting. CNC cutting-edge technology, on contrary, provides the highest precision and accuracy of every part, which reduces the chance of manufacturing errors and resulting in substandard products. We have an experienced technical team who continuously carry out technological innovation and process improvement to make sure that our products are always at the top of the industry in terms of technology. Our commitment is to meet the needs of our customers for components that are high-performance by developing technology continually.