This allows the fuel and air to collide in the combustion chamber, where they have an opportunity to explode together (again at a very microscopic level). Tiny boom; punchy little bugger, that! It's moving this thing called a piston that helps propel the car forward. Opens the gates for things to happen Starts out like nothing. Properly mixing fuel, and air together in the combustion chamber is yet another vital part of creating an explosion.JSONObject They wont play nice and the explosion will not be as big of a bang when it happens, making your engine suck.

Flagstaff Engine Economy — Gas Mileage on Your Sedan at Altimontes It is a method of identifying an efficient state — when the engine requires minimum fuel to provide maximum power. A pretty important aspect to be sure, as we want our fuel tanks ideally working for every drop of gasoline that enters its depths. Combustion Chambers come in very useful at this point.

Besides, have you noticed that there are so many different shapes of the combustion chambers depending on types of engine. Some are round, while others possess a different kind of shapes. What is interesting here, though is that the shape of our combustion chamber can have a huge influence on how well we mix air and fuel. This to blend perfect fuel and air when ignite, which make a best explosive can give you an extra power. This means the engine can run better and more efficient. It can also offset reduced running rough to maintain a long life cycle of the engine.

So they are carried out by the components of an internal combustion chamber engine that make other things work well. The spark plug is one of the most important part in it that make electric ignition, A small things call as a Spark Plug. The engine then ignites this mixture of air and fuel. Your engine would stop running because the fuel and air could not burn to release the energy that was moving your car, without this spark plug.

A combustion chamber engine of large volume is the desire for faster and more powerful car. Others will opt to focus on engine mods for added performance increases, and a few may even go into more complex engines builds. If it is in cetane rating and fuel type, with an engine customization might mean a different shape of the combustion chamber or some extra turbocharger work.

A turbocharger is a straightforward gadget that helps the motor to inhale better. The basic idea is to stuff more air in so you can burn fuel and make power. And that's why engine swaps exist. However, remember that changing an engine can be a bit risky and in other cases it could end up costing you big time! This is why it would only be wise to have a professional working on your engine and making nothing goes wrong whatsoever.

Humans have so many components that must interact properly. The will need some simple information about this so you can learn How engines work in reality. Comcubstion chamber is the vital part of engine where fuel as well air meet together and do their work. This will create the optimum path for flame travel on opposing cylinder which in turn return the most power out of your engine.

We adhere to the strictest standards of quality control to ensure the reliability and performance of each component Quality control is conducted throughout the entire process of production from the purchase of raw materials to the testing of the combustion chamber engine In order to ensure that our product's quality are constantly improved we perform regular audits and improvements Our aim is to win the trust and continue to work with of our customers through providing quality products that are of the highest standard and to be a leader in the industry

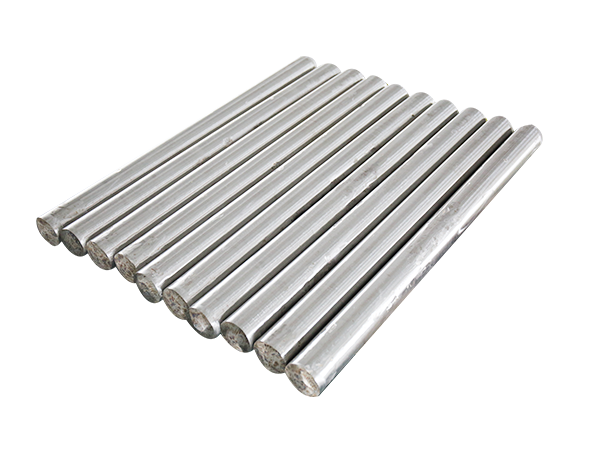

Our company offers customized services, and can produce turbine components from an array of combustion chamber engine metals to meet the needs of customers. Our flexible production flow, advanced process technology, and our capacity to meet particular requirements, like size shape, performance, or shape can allow us to meet any requirement. We work closely with our clients to comprehend their needs specific to them and the application scenarios and provide professional advice and solutions. Our diverse selection of materials, processing capabilities and application-specific requirements allow us to meet the needs of a variety of industries and. With customized services, we help our customers optimize product performance and cost as well as increase market competitiveness.

We can create turbine parts with high precision and consistency through combustion chamber engine, machining and forging processes. Casting allows us to create parts with intricate designs, strong and durability. Forging gives parts a more durable and superior mechanical property. CNC machining technology, on the contrary, provides the highest precision and accuracy of every part, which reduces the chance of the chance of errors and producing substandard products. Our experienced technical team is always working on technological innovations and process improvements in order to ensure that our products remain at the leading edge of industry technology. We are committed to meeting the demands of our clients for high-performance parts by constantly advancing technology continuously.

Our customer support is comprehensive and includescombustion chamber engine, technical support, and after-sales services to ensure that our customers get the best experience possible. Our team of experts will evaluate the requirements of the customer and offer appropriate product solutions and suggestions. We provide technical support starting with the selection of products to installation and commissioning. This ensures that our clients are able to use our products without any issues. We have a well-developed after-sales process that allows us to swiftly respond to issues and needs of customers, and to provide effective and prompt solutions. We are determined to develop long-term relationships with our clients and gain their trust and respect by offering high-quality services.