Inconel bolts are famous for being incredibly robust and durable. Inconel; it's made from a special Nickel and Chromium alloy that is melt-spun into wire form. A very unique, super strong material that can withstand intense heat as well as extreme pressure without warping. Inconel is so ideal for creating bolts which need to operate in harsh and aggressive environments where other materials will suffer that.

However, Inconel bolts are more commonly used in far higher-stress jobs such as aircraft engines and pharmaceutical manufacturing equipment. In such a situation, the bolts are key components and have extreme functionality like high temperature resistance abilities, ability to bear huge pressure load capacity as well as rust protection against metal erosion. The specifics are made just so in the right way to do these tough jobs, and one of those things is Inconel bolts. They are crafted with perfect sizes and accurate dimensions so they perform incredibly well while playing under such rigor surroundings.

Also you can have then manufactured for your self, how cool is that. These bolts can be made in varied sizes, style as well as coatings to suit what you require. This is highly because of bolts being different in need for each job. For instance, a bolt used in an aircraft should differ from that of one meant for use at sea. These Custom Inconel bolts can prove to be extremely helpful in this situation since it helps you get the most suitable for your job and that makes sure, more than anything else on safety as well.

The Inconel bolts are extremely strong and very hard in nature. They are also able to withstand high heat, heavy pressure and can even be used in environments where most bolts would corrode. This makes them perfect for jobs that conventional bolts fail or break. Furthermore, Inconel bolts do not experience fast fatigue and it altezaalama the crack. Basically, these bolts can be used much longer than any other type of bolt. Inconel bolts will do more than impress you, and they will deliver at any level.

The folks who fabricate Inconel bolts can never stop innovation. Our bolts are designed with strength in mind and we continually test new ideas on how to make them better, stronger as well as anti-rust for long durability. They are also one of the best and latest technique that is used to produce bolts which provide very high quality. This continued innovation helps ensure that Inconel bolts are still favored for tough work and demanding applications.

Our comprehensive customer service includes pre-sales consulting technical support and after-sales services to ensure that customers enjoy the most enjoyable experience Our expert team will assess the needs of customers and offer appropriate product suggestions and solutions We provide technical support starting with the selection of products through installation and commissioning This ensures that our customers are able to enjoy our products without issues For after-sales support we have developed an efficient service system that can respond swiftly to customer issues as well as needs and provide inconel bolts manufacturer and efficient solutions Our goal is to create long-term relationships and gain customers trust and their satisfaction by providing superior customer service

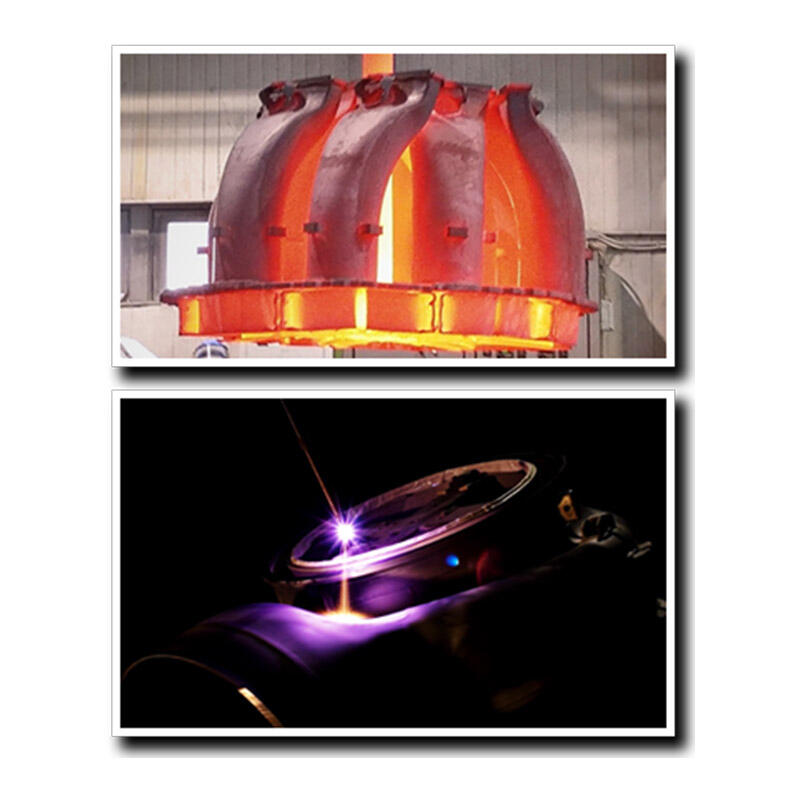

Our company can fabricate highly precise and stable turbine parts through casting forging, and CNC machining. Casting allows us to create components with complex forms, high strength and long-lasting. Forging can give parts a more durable and superior mechanical property. CNC technology for machining, on other hand, ensures high precision and consistency of every part, which reduces the chance of the chance of errors and producing substandard products. Our technical team that constantly carries the latest technological advancements and process improvement to make sure that our products are always at the top of the industry in terms of inconel bolts manufacturer. We're determined to meet our customers' demands for high-performance turbine components through continuous technological advancement.

Our company can provide customized services and is able to fabricate turbine components from an array of high-temperature alloys in accordance with the requirements of customers. No matter what inconel bolts manufacturer, size or performance requirement, we can achieve it with our flexible production process and cutting-edge technology for process. We work closely with clients to comprehend their needs as well as the various scenarios they might encounter and give them professional assistance and suggestions. We have a variety of materials and processing capabilities to meet the unique requirements of different industries and applications. We aid our clients in improving their competitiveness on the market by offering custom-designed services that improve efficiency and lower costs.

We adhere to inconel bolts manufacturer of quality control in order to guarantee the performance and reliability of every component. Quality control is performed throughout the entire manufacturing process starting from the purchase of raw materials through the test of the finished product. In order to ensure that our product's quality is continuously improved, we also conduct regular audits and improvement. Our goal is to win the trust and cooperation of our clients by offering top quality products and to become a leader in the industry.