Get better turbine performance with our advanced thermal barrier coatings

Turbine blades are a key components in the operation as well as the efficiency of the turbine in many applications. I.B.T is a technology company specializing in advanced solutions for a more efficient turbine utilizing state-of-the-art thermal barrier coatings. We hope our next-generation coatings will result in better efficiency and productivity of jet turbine wheel turbine blades. Let’s take a look at how our thermal barrier coatings can improve turbine performance.

When it comes to turbine blade materials, the longer and more durable the better as far as effectiveness of the whole system is concerned. At O.B.T we focus on producing high quality protective coatings, which serve to prolong the life of turbine blades. Our coated products are a defense of turbine blades against the elements and operational strains, guaranteeing turbine compressor wheel blades that can stand the test of time. With our protective coatings, you can extend the service life of your turbine blades and use your turbines at peak performance for decades.

It is essential for the performance of turbine system to manage heat efficiently. O.B.T Special high temperature coatings designed to increase efficiency of turbines. Our coatings are excellent for insulating and preventing heat loss, and reducing heat transfer across turbine blades, as well as for maintaining the edge of the blade. Our coatings improve heat turbocharger turbine wheel transmission and therefore turbine performance, productivity and results. You can improve the efficiencies of your generators with our unique antioxidation coatings.

For turbine systems, the costs of maintenance can add up to the overall operating costs very quickly. O.B.T is aware of the value of money and provides a quality, lasting coating for turbine blades, which will save you money on maintenance down the line. Our finishes are designed to outlast the competition reducing the necessity for constant repairs and replacements. Invest in our coatings, and you can pay less on maintenance and achieve a lower cost of turbine systems. Trust O.B.T to fill your order for coatings designed to be dependable and provide cost savings, allowing you to meet your operation’s turbo turbine wheel budget and get long lasting results.

Reliability in turbines is paramount, and O.B.T has a solid history of improving both reliability and performance with the use of our premium thermal barrier coatings. Our coatings are engineered to the highest standards, providing unerring dependability and efficiency when in operation in turbines. With our thermal barrier coatings on your turbine systems, you can increase reliability, reduce downtime, and optimize performance. At The O.B.T Receives, our commitment to quality and steam turbine wheel innovation ensures that our coatings will meet and exceed your exacting needs and performance for unsurpassed reliability and performance in your turbine technology systems.

Our customer support is comprehensive and includesThermal barrier coatings on turbine blades, technical support, and after-sales services to ensure that our customers get the best experience possible. Our team of experts will evaluate the requirements of the customer and offer appropriate product solutions and suggestions. We provide technical support starting with the selection of products to installation and commissioning. This ensures that our clients are able to use our products without any issues. We have a well-developed after-sales process that allows us to swiftly respond to issues and needs of customers, and to provide effective and prompt solutions. We are determined to develop long-term relationships with our clients and gain their trust and respect by offering high-quality services.

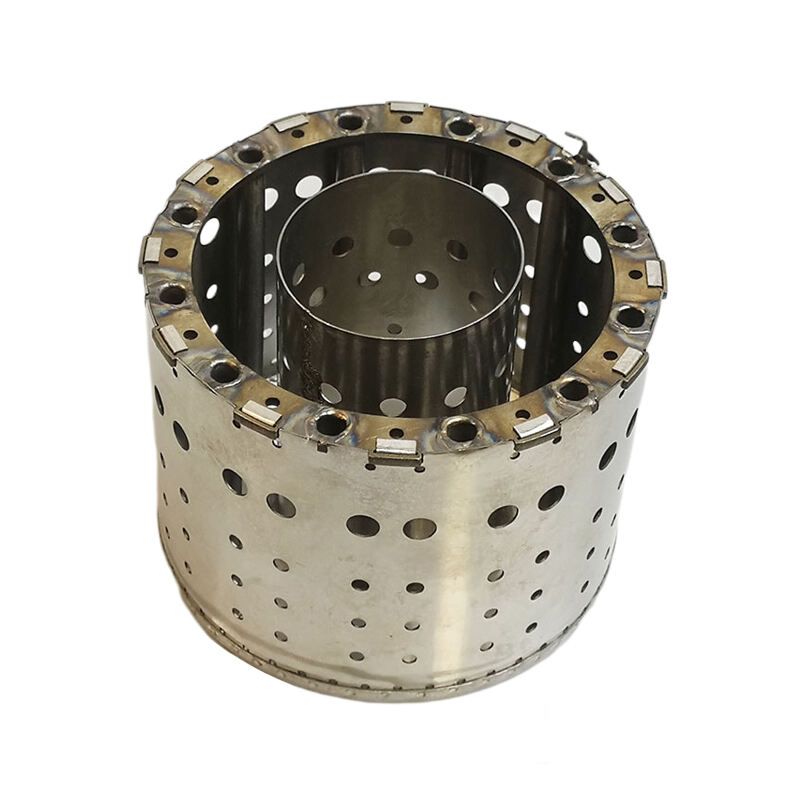

Our company is able to fabricate highly precise and stable turbine components through casting, forging and CNC machine processes. The casting process permits us to Thermal barrier coatings on turbine blades with complex shapes and high durability, while the forging process gives the parts better mechanical properties and longer lasting. CNC cutting-edge technology, on contrary, provides the highest precision and accuracy of every part, which reduces the chance of manufacturing errors and resulting in substandard products. We have an experienced technical team who continuously carry out technological innovation and process improvement to make sure that our products are always at the top of the industry in terms of technology. Our commitment is to meet the needs of our customers for components that are high-performance by developing technology continually.

Our company is committed to strict quality control standards to guarantee the best performance and reliability of every component Every step of the production process is controlled for quality starting from the purchase of raw materials all the way to the final test of the product We also carry out regular quality audits as well as adjustments to ensure constant improvements in product quality Our goal is to win the trust and continue to work with of our clients by offering top quality products and to become an Thermal barrier coatings on turbine blades

Our company offers customized services and is able to fabricate turbine components from many different high temperature alloys based on customer specifications. Our flexible production flow along with our advanced process technology and our capability to meet Thermal barrier coatings on turbine blades, such as size and shape, as well as performance can allow us to meet any requirement. We work closely with clients to comprehend their needs and the potential scenarios for their applications, and then give them professional guidance and solutions. Our wide range of products processing capabilities, processing capabilities, and specific requirements for applications allow us to fulfill the particular requirements of various industries and application. With our customized services, we help our customers optimize efficiency and costs of their products, and improve market competitiveness.