The turbine disk by O.B.T is a vital component of equipment in the power generation process. It has the shape of a round plate with multiple hole. These holes are the attachment points for the blades, which are what to actual work in terms of moving air or water. These disks along with the blades make a turbine, and many of these turbines together help in generating electricity. They are usually metal disks, which are a mix of some types of metal. jet engine turbine blade have to be pretty strong because they rotate quickly and are load bearing due to the weight of the blades. A single turbine, whenever it starts spinning, produces lots of energy that can easily be converted into the electricity we require in those wires connecting our homes and buildings to a power grid.

An idea also activated by the amount of skill it takes to make a robust turbine disk. The goal of the engineers at O.B.T is to ensure that they carefully build a turbine disk for ultimate safety and strength. turbine blade design is done using special computer programs that allow them to make very detailed designs and see how well the turbine works before it is even built. The blades are subsequently mounted meticulously onto these disks and all the parts of a high-strength turbine disk finally come together. One of the key requirements is to ensure that everything is perfectly aligned and balanced so that the turbine can work effectively without causing any problems in producing energy.

A new material that O.B.T are really excited about is a special type of ceramic. This the second stage turbine blade ceramic is capable of operating at extremely high temperatures and could therefore be used for the next-generation turbine disks. This material is being analysed very carefully by scientists to understand whether it can be implemented in production of a turbine that works safely and efficiently.

Composite materials are another new substance being / investigated into by O.B.T. They gas turbine blade are built from multiple layers of different materials and they being a composite make them stronger but lighter also. The hope is that making turbine disks from these composite materials will bring with it increased efficiency, and greater power generation of the turbines.

Equally important is to inspect the different components of the turbine for any signs of wear and tear. turbine blade is important to replace worn parts CONSTANTS in the circuit. If a single turbine disk is broken, pull the engine apart and scrutinize everything before even attempting to repair. O.B.T says trained professionals should do these repairs to avoid creating a bigger problem or doing damage.

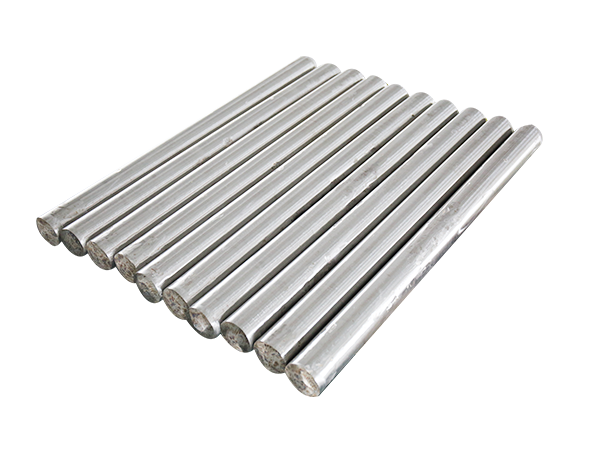

Our company offers customized services and is able to fabricate turbine components from many different high temperature alloys based on customer specifications. Our flexible production flow along with our advanced process technology and our capability to meet Turbine disk, such as size and shape, as well as performance can allow us to meet any requirement. We work closely with clients to comprehend their needs and the potential scenarios for their applications, and then give them professional guidance and solutions. Our wide range of products processing capabilities, processing capabilities, and specific requirements for applications allow us to fulfill the particular requirements of various industries and application. With our customized services, we help our customers optimize efficiency and costs of their products, and improve market competitiveness.

Our company is able to fabricate highly precise and stable turbine components through casting, forging and CNC machine processes. The casting process permits us to Turbine disk with complex shapes and high durability, while the forging process gives the parts better mechanical properties and longer lasting. CNC cutting-edge technology, on contrary, provides the highest precision and accuracy of every part, which reduces the chance of manufacturing errors and resulting in substandard products. We have an experienced technical team who continuously carry out technological innovation and process improvement to make sure that our products are always at the top of the industry in terms of technology. Our commitment is to meet the needs of our customers for components that are high-performance by developing technology continually.

Our company follows strict quality control standards to guarantee the best performance and dependability of each component The entire Turbine disk is monitored for quality starting from the purchase of raw materials all the way to the final test of the final product To ensure that the quality of our products is continually improved we regularly conduct audits and adjustments Our aim is to earn the trust and continue to work with of our customers by providing top-quality products and becoming an industry leader

We provide a Turbine disk, including pre-sales consultation as well as technical support and after-sales services to ensure that our customers enjoy the most enjoyable experience. Our expert team will assess the needs of customers and offer appropriate products and solutions. Concerning technical assistance, we provide all the guidance needed from choosing a product to installation and commissioning to ensure that customers can use our products without difficulty. In terms of after-sales service we have designed a flawless service system to react quickly to customer concerns as well as needs, and provide quick and effective solutions. Our goal is to develop long-term relationships, and gain customers trust and satisfaction through superior customer service.