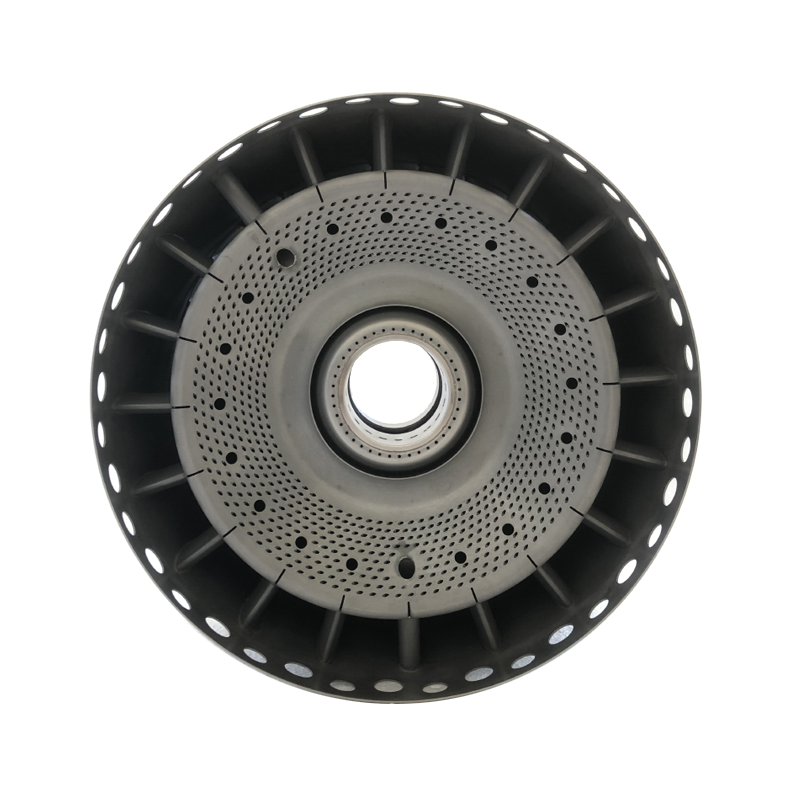

An energy generating turbine blade is a key component. It operates as a cover that goes inside a machine called a turbine. Turbine liner is unique to enable the turbine to be more effective and more economical, allowing more energy to be produced with less waste.

The turbine liner consists in durable, long-lasting materials. These materials help to make the turbine liner tough and provides durability. If the turbine liner is healthy, only then can the turbine perform its purpose. Because the turbine liner helps guide hot gases resulting from the combustion of fuel through the turbine to generate energy. The turbine can work better, the better the turbine liner.

Regular inspection and maintenance of the second stage turbine blade is required to ensure the smooth operation of the turbine liner. Frequent visual inspection of gas turbine liners is an essential safety practice. And if they grow old or worn we also have to replace them. Water turbine liners are used for maintaining safe flow rates, If the turbine liner is damaged, the turbine is not operational. This can create challenges for generating electricity, and can increase costs for power plants.

The turbine liner component can contribute a lot towards energy generation & minimising pollution. When the turbine liner does its job it works to produce energy with less harmful gas that could cause harm to the environment. This helps a lot to keep our planet and air clean and safe for you and me. O.B.T's turbine liners help plants produce more power while reducing pollution, helping us all.

Every year, new designs and technology continue to advance turbine liners. O.B.T, which makes some of the parts used in turbines, can now use better technology to make turbine liners even stronger and more efficient. So, this allows generation to generate with much more efficiency, not to mention, also less pollution — which as we know is critical for the future.

The turbine liners are made using the latest techniques and materials available, according to O.B.T. They are constructed to withstand extensive periods of time and high quality. O.B.T’s turbine liners are in good condition, and regular checks and care help provide that assurance. This generates an energy from power plants much more reliable and efficient and less polluting.

We provide a turbine liner, including pre-sales consultation as well as technical support and after-sales services to ensure that our customers enjoy the most enjoyable experience. Our expert team will assess the needs of customers and offer appropriate products and solutions. Concerning technical assistance, we provide all the guidance needed from choosing a product to installation and commissioning to ensure that customers can use our products without difficulty. In terms of after-sales service we have designed a flawless service system to react quickly to customer concerns as well as needs, and provide quick and effective solutions. Our goal is to develop long-term relationships, and gain customers trust and satisfaction through superior customer service.

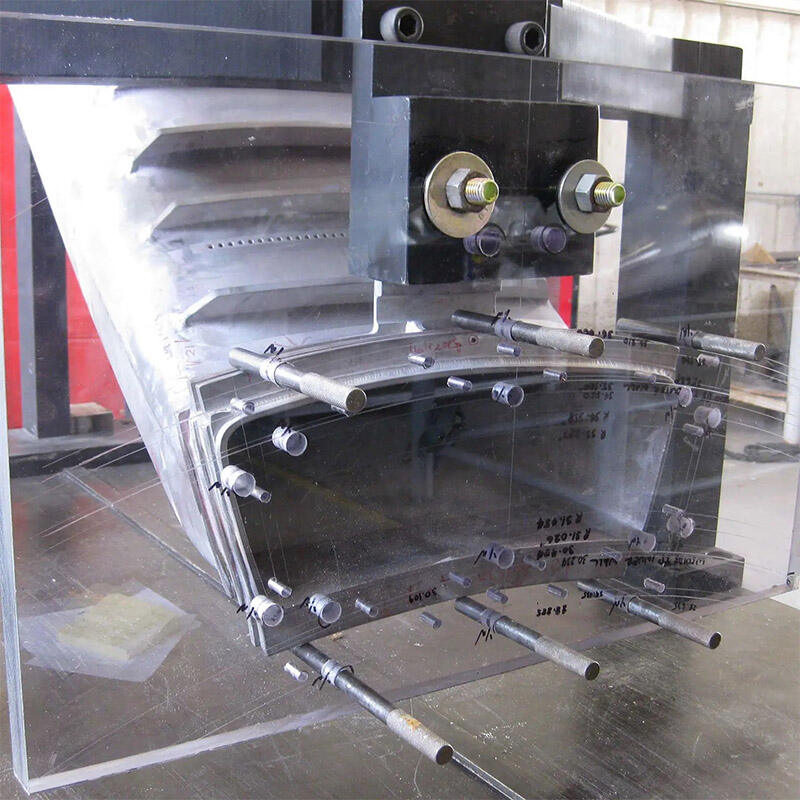

Our company is able to fabricate highly precise and stable turbine components through casting, forging and CNC machine processes. The casting process permits us to turbine liner with complex shapes and high durability, while the forging process gives the parts better mechanical properties and longer lasting. CNC cutting-edge technology, on contrary, provides the highest precision and accuracy of every part, which reduces the chance of manufacturing errors and resulting in substandard products. We have an experienced technical team who continuously carry out technological innovation and process improvement to make sure that our products are always at the top of the industry in terms of technology. Our commitment is to meet the needs of our customers for components that are high-performance by developing technology continually.

We follow turbine liner for quality control to ensure the performance and reliability of every component. The entire process of production is subject to quality control, from the raw material purchase until the final testing of the product. We also regularly conduct quality audits and improvements to ensure continuous improvement of product quality. We are determined to gain the trust of our clients and to maintain their long-term relationship by offering high-quality products.

Our company provides turbine liner and can make turbine components in many different high temperature alloys according to the requirements of customers. Whatever the size, shape, or performance requirement, we are able to meet it using our flexible production processes as well as our advanced processes. We collaborate closely with our customers to comprehend their needs and applications scenarios and then give them professional assistance and suggestions. We have a broad range of processing and materials to meet the unique requirements of different sectors and application. We help our clients improve their competitiveness in the marketplace by offering custom-designed services that improve performance and reduce costs.