Magnetic Resonance Imaging (MRI) scans of dams, turbines help avoid shaft fracture in power generation machinery. Every time we turn on the light, watch TV or charge our cell phones what is being used there it comes from electricity. All this electricity pours out of power plants, which play a crucial role in producing it: the turbine shaft.

Turbine shaft- This is what the turbine uses to turn on the blades. Turbine: A machine that uses steam or water to spin its blades. These fast spinning turbines are driven when steam or beta flows over the blades. As the blades revolve it causes the turbine shaft to move. A spinning motion in the generator results because the turbine spins easily, which generates electricity. Without turbine shaft, power plants wouldn't be able to produce the electricity required in our homes/schools/businesses.

The turbine shafts are virtually indestructible steel made for hot-high pressure environments where they produce all of that power. These shafts are going through hell, and obviously they must be right to put a car together properly. You simply need to pay more attention and that is it, add them regularly if necessary in order for the work goes perfectly. Once a turbine breaks, or doesnt perform correctly then there are major problems at the power plant and that turns into alot of you turning on lights where nothing will shine.

As technology continies 0 develop which facilitates the use of now cer stronger and more durable build materians, even the previously known basic problem whereby turbine shafts can whist control power is progressively becoming a thing of the past This has indeed been commented upán in by some authors (Huiming 2010). The researchers said new materials can produce power with more than twice the efficiency and double the temperature and pressure sustainability. Furthermore, with the use of 3D printers, we can now incorporate new and innovative techniques to aid in designing better turbine shafts. For instance, unique steering shafts are possible courtesy of this tech and that can enable the driving components to work more efficaciously than they have in years.

Some of the common ailments that occur to a turbine shaft may be Corrosion: This is when water or steam was able to contact metal for too long and it decays. Eventually, it will also be an arch-enemy of the shaft by vibrating and drying its strength that leads to ulteriorly damages. But these same issues are what often slip through the cracks to later lead to costly and dangerous case of product downtime due equipment failures. By making use of the regular measures to get done with these things, you can be safe on both ends. Special coatings will even protect turbine shafts from corrosion and other maladies.

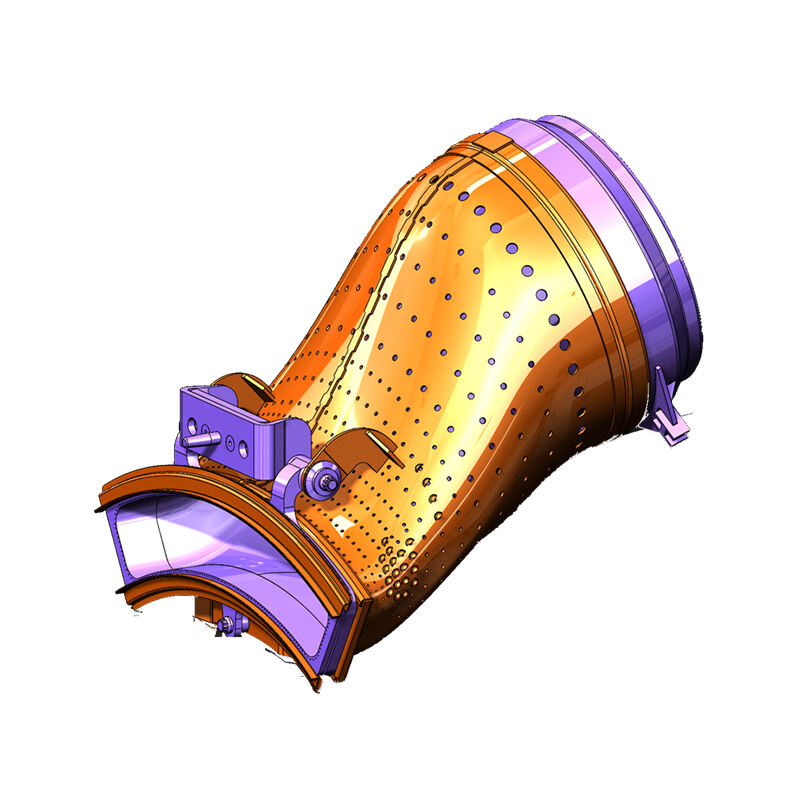

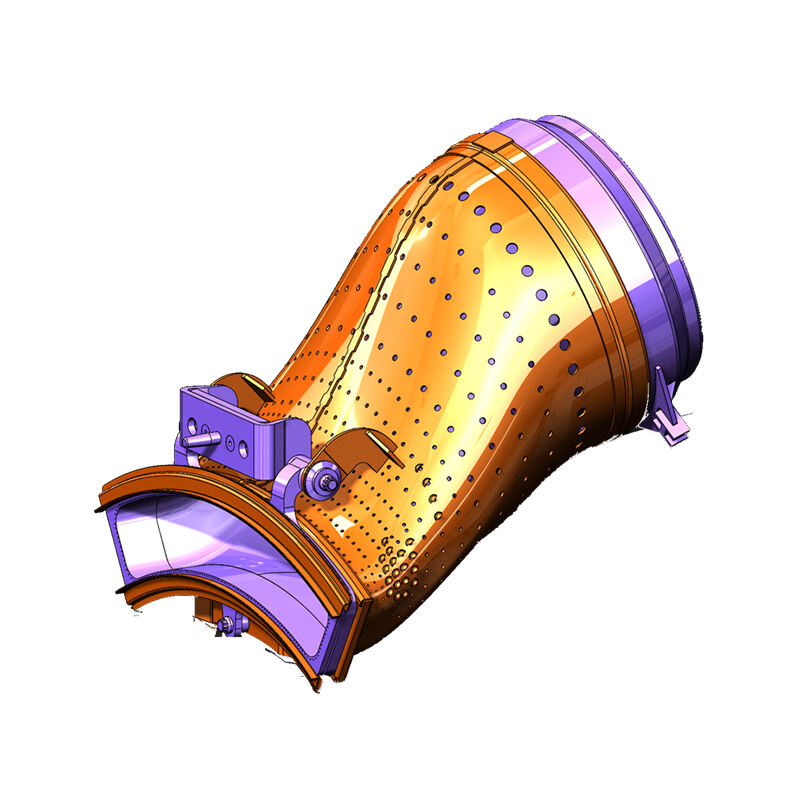

Our company has the ability to create highly precise and reliable turbine parts through casting turbine shaft, and CNC machining processes. Casting allows us create components with complex designs, strong and long-lasting. Forging provides parts with a better mechanical quality and longer durability. CNC machining, on the contrary offers high precision and consistency for every component. This reduces errors and inferior products. Our technical staff is constantly developing technological advancements and process improvements to ensure our products are at the forefront of industry technology. We're committed to meeting our customers' demands for high-performance turbine components by continual technological advancement.

Our company offers specific services that is able to manufacture turbine parts from various high-temperature alloys in order to satisfy the demands of customers. Our flexible production flow as well as our state-of-the-art process technology and our ability to satisfy particular requirements, like size and shape, as well as performance will allow us to meet every requirement. We are in constant contact with our customers in order to fully understand their needs specific to them and the application scenarios, and provide them with expert technical guidance and solutions. We have a rich selection of processing and materials that can meet the turbine shaft of various sectors and application. Through customized services, we assist our customers in optimizing their product performance and cost, and improve market competitiveness.

Our customer support is comprehensive and includesturbine shaft, technical support, and after-sales services to ensure that our customers get the best experience possible. Our team of experts will evaluate the requirements of the customer and offer appropriate product solutions and suggestions. We provide technical support starting with the selection of products to installation and commissioning. This ensures that our clients are able to use our products without any issues. We have a well-developed after-sales process that allows us to swiftly respond to issues and needs of customers, and to provide effective and prompt solutions. We are determined to develop long-term relationships with our clients and gain their trust and respect by offering high-quality services.

We follow turbine shaft for quality control to ensure the performance and reliability of every component. The entire process of production is subject to quality control, from the raw material purchase until the final testing of the product. We also regularly conduct quality audits and improvements to ensure continuous improvement of product quality. We are determined to gain the trust of our clients and to maintain their long-term relationship by offering high-quality products.