Creating the turbine impellers is a vital part of many machines we often use. They are grouped here because they take place in pumps and generators. The operation of the various machines requires these screws to allow liquids, water and gas to be moved through which is called an impeller. O.B.T impeller turbine are not similar to the conventional pump applications but they come in many types of constructions and each type construction is designed for a specific job or task. This article discovers different types of these widely used impeller and its application.

When selecting turbine impeller here are few factors to consider. It makes the impeller move through the liquid which is trying to pump from one place to another. Propeller has to be designed in such a way that it should work fine as per conditions available. It may not work as expected, or it might simply be an inefficient application if the way that we built it was not suited for the environments. In this article, you will learn what to consider while selecting the O.B.T turbine impeller design and how it can help in making efficient decisions.

There are a variety of strengths and weaknesses depending on the engine type with each different design turbine impeller. Certain designs are good for lower-pressure applications while others perform better at high pressure. Each designs have their equal pros and cons. The following section will examine the pros and cons of several types of turbine impeller. Radial flow pushes the liquid from outside toward in, axial flow will where you want to pushing along your z-axis and mixed-flow combines both of them. O.B.T gas turbine impeller designs will help you to identify which one of them could be a good fit for your application.

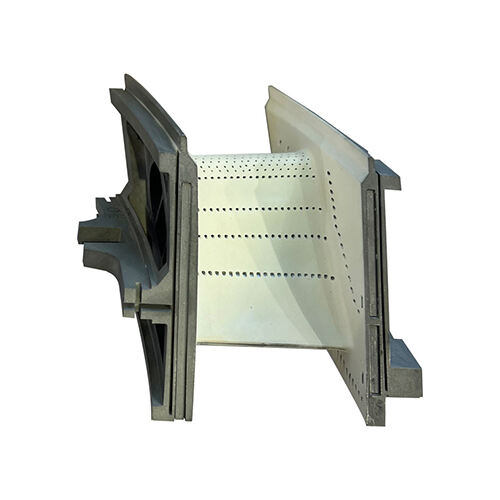

Sizes and Shapes is the fundamental principle in designing rotors. A series on steam turbine impeller which you may encounter in application, and which also feature some of those most often used nowadays. Some are open, others have closed radial vanes with different design elements for fluid's pumping.

Turbine impellers are shaped and angled as required to keep pump within or above its design efficiency. The turbine impeller blades are what physically move the liquid so its shape matters a lot for efficiency. In particular, we provide a straight blade having a curved blade in which meant that to force any liquid forward considering simple features than twisted ones. The blade form also influences the general efficiency of an impeller.

We provide a Turbine impeller types, including pre-sales consultation as well as technical support and after-sales services to ensure that our customers enjoy the most enjoyable experience. Our expert team will assess the needs of customers and offer appropriate products and solutions. Concerning technical assistance, we provide all the guidance needed from choosing a product to installation and commissioning to ensure that customers can use our products without difficulty. In terms of after-sales service we have designed a flawless service system to react quickly to customer concerns as well as needs, and provide quick and effective solutions. Our goal is to develop long-term relationships, and gain customers trust and satisfaction through superior customer service.

We follow Turbine impeller types for quality control to ensure the performance and reliability of every component. The entire process of production is subject to quality control, from the raw material purchase until the final testing of the product. We also regularly conduct quality audits and improvements to ensure continuous improvement of product quality. We are determined to gain the trust of our clients and to maintain their long-term relationship by offering high-quality products.

Our company offers specific services that is able to manufacture turbine parts from various high-temperature alloys in order to satisfy the demands of customers. Our flexible production flow as well as our state-of-the-art process technology and our ability to satisfy particular requirements, like size and shape, as well as performance will allow us to meet every requirement. We are in constant contact with our customers in order to fully understand their needs specific to them and the application scenarios, and provide them with expert technical guidance and solutions. We have a rich selection of processing and materials that can meet the Turbine impeller types of various sectors and application. Through customized services, we assist our customers in optimizing their product performance and cost, and improve market competitiveness.

Our company is able produce highly accurate and consistent turbine parts by casting, forging, and CNC machining processes. The casting process allows us to produce parts with intricate shapes and strong durability, while the forging process gives the parts better Turbine impeller types and longer lasting. CNC machining technology, on the contrary, guarantees consistent and high-quality of every part, which reduces the chance of manufacturing errors and resulting in substandard products. We have a highly skilled technical team that constantly carries out technological innovations and process improvement to make sure that our products stay in the forefront of industry in terms of technological. We are committed to meeting the requirements of our customers for components that are high-performance by developing technology continually.