Have you ever been introduced to a turbojet diffuser? However, this small component inside a jet engine is truly unique, as it enhances the engine's speed and performance. The O.B.T diffuser in turbojet engine can be likened to a type of funnel. Assisting in guiding air into the jet engine, it enhances the efficiency of turbojet engines, similar to how a funnel aids in pouring water into a narrow container without any spills. The jet engine would experience reduced strength and efficiency without the turbojet diffuser. This method could not have traveled at such high speeds or utilized fuel in that manner.

The use of a turbojet diffuser can result in significant fuel savings and enhance the performance of jet engines. A jet engine is an aircraft device that derives thrust by pulling in atmospheric air, mixing it with jet fuel, and burning the mixture in a combustion chamber to create energy with the help of external oxygen. This O.B.T turbine diffuser is important as it enhances the mixing of fuel and air, leading to higher combustion efficiency. This ultimately results in reduced fuel consumption during flights, promoting both cost savings and environmental sustainability. Using less fuel will result in fewer pollutants being emitted, ultimately leading to a more environmentally friendly mode of air travel.

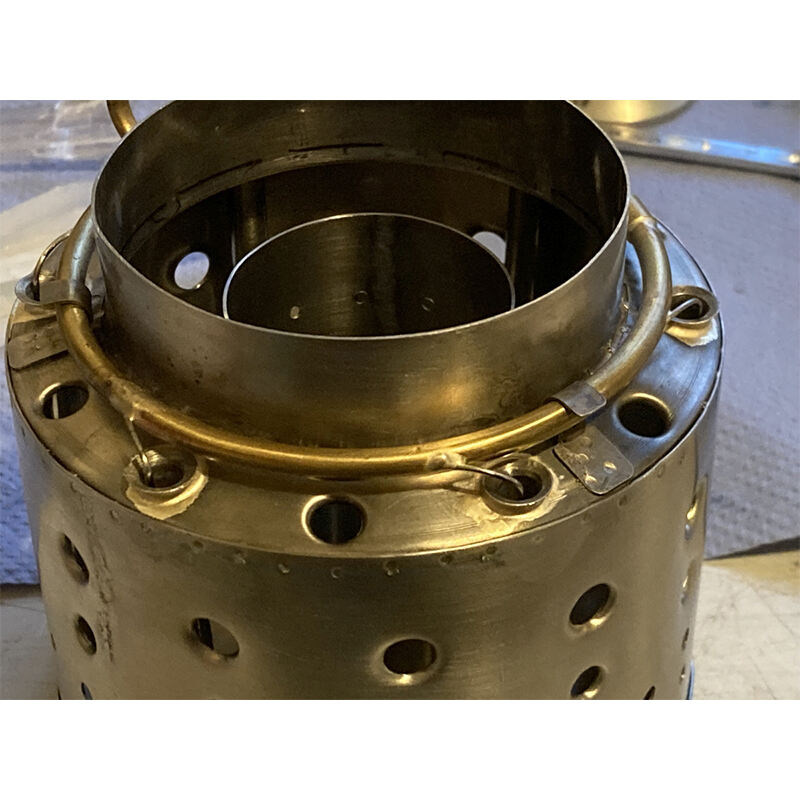

This is achieved through a fluid mechanics idea commonly used in turbojets known as a diffuser. This is simply an elegant manner of stating that it examines the movement of fluids, such as liquids or gases, as they flow. The O.B.T turbine engine diffuser slows down and reduces the pressure of the air passing through it. Materials restrict airflow, reducing the work needed to blend with fuel. The diffuser's shape needs to be precise to guarantee effective air/fuel mixing and modulation characteristics. That unique shape is essential for everything to function harmoniously.

The investigation of the movement of objects in the atmosphere. When it comes to the airflow surrounding a jet engine, we prefer it to be smooth and laminar from all angles. Jet engines require a small turbojet diffuser in order to function effectively while in flight. The odd appearance of the O.B.T diffuser turbine engine is designed to reduce drag, which refers to the air slowing down before entering the engine. Air resistance prevents the object from moving easily by pushing against it. Reduced drag leads to increased speed and efficiency for the jet engine, benefiting everyone involved.

A turbojet diffuser significantly impacts the efficiency of a jet engine's operation. By effectively blending air and fuel, the engine is able to generate increased power while using less fuel. This indicates that the jet can fly at a higher speed and lift off with less fuel compared to flying normally from airports like Heathrow, Chicago, or Sydney without passengers. Engineers use various methods to create jet engines that are more robust, quicker, and more effective in O.B.T diffuser turbine and they play a major role in the future of aviation.

Our company follows strict quality control standards to guarantee the best performance and dependability of each component The entire Turbojet diffuser is monitored for quality starting from the purchase of raw materials all the way to the final test of the final product To ensure that the quality of our products is continually improved we regularly conduct audits and adjustments Our aim is to earn the trust and continue to work with of our customers by providing top-quality products and becoming an industry leader

We offer a comprehensive customer service that includes pre-sales consultation as well as technical support and after-sales assistance so that our customers have the most pleasant experience In the pre-sales stage our experienced team will understand the customer's needs in detail and provide the most appropriate suggestions for products and solutions For technical support we offer full guidance from product selection to installation and commissioning to ensure that our customers use our products with ease We have developed an after-sales program that enables us to quickly respond to customer concerns and issues and to provide effective and timely solutions We are determined to develop long-term relationships with our clients and Turbojet diffuser their trust and satisfaction through offering high-quality services

Our company offers customized services and is able to fabricate turbine components from many different high temperature alloys based on customer specifications. Our flexible production flow along with our advanced process technology and our capability to meet Turbojet diffuser, such as size and shape, as well as performance can allow us to meet any requirement. We work closely with clients to comprehend their needs and the potential scenarios for their applications, and then give them professional guidance and solutions. Our wide range of products processing capabilities, processing capabilities, and specific requirements for applications allow us to fulfill the particular requirements of various industries and application. With our customized services, we help our customers optimize efficiency and costs of their products, and improve market competitiveness.

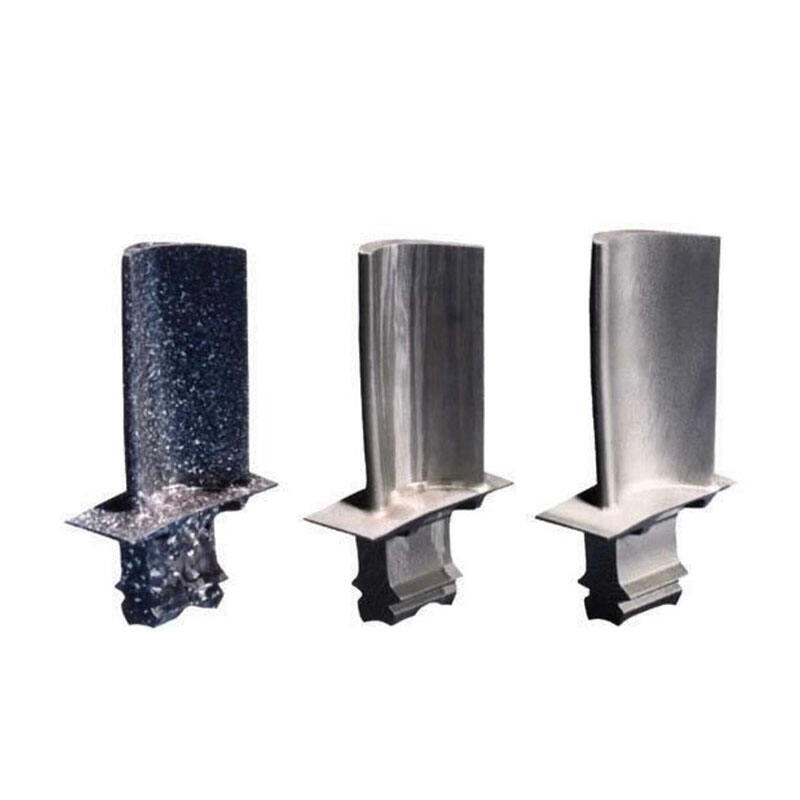

Our company is able to fabricate highly precise and stable turbine components through casting, forging and CNC machine processes. The casting process permits us to Turbojet diffuser with complex shapes and high durability, while the forging process gives the parts better mechanical properties and longer lasting. CNC cutting-edge technology, on contrary, provides the highest precision and accuracy of every part, which reduces the chance of manufacturing errors and resulting in substandard products. We have an experienced technical team who continuously carry out technological innovation and process improvement to make sure that our products are always at the top of the industry in terms of technology. Our commitment is to meet the needs of our customers for components that are high-performance by developing technology continually.