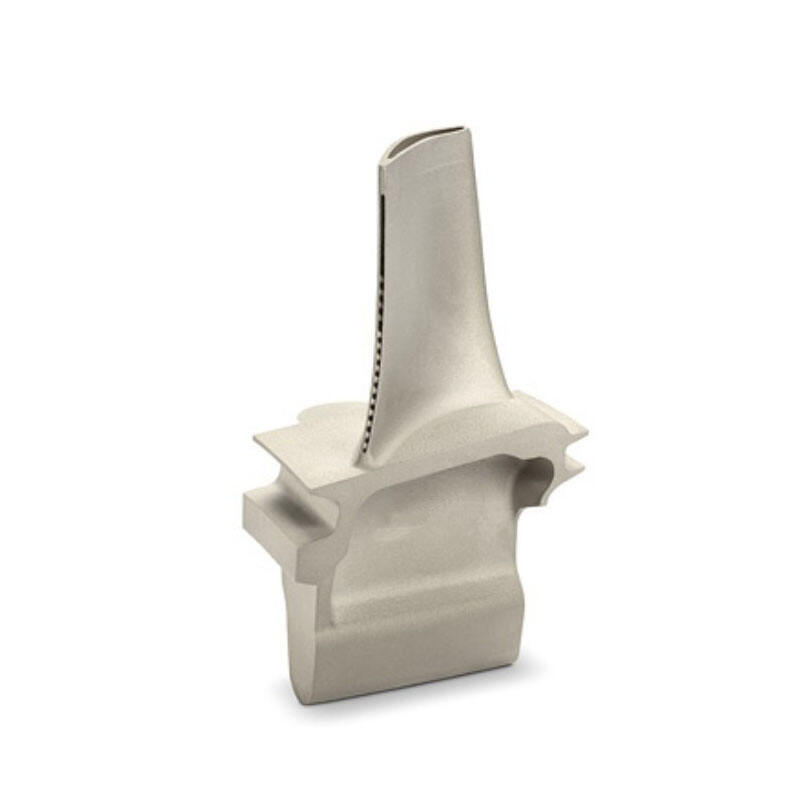

In the it sounds kinda of...upway, have you ever looked up and seen a plane thousands of feet in the air? Photo by Sohel Patel on PexelsAmazing! Ever wondered how does it happen that plane stays in the air and flies? Jet Engine Turbine BladeOne of the most essential parts which enables planes to fly really fast is a jet engine turbine blade. Since these blades are made of very tough material, it can withstand a high amount of Heat and pressure.

The blades of jet engine turbines are manufactured out of incredibly strong materials for a reason. Nickel-based alloys, titanium and ceramic composites are amongst the most commonly used materials. These materials are very strong and can withstand extremely high temperatures without melting. This strength is necessary to get them up into the upper atmosphere and cruising at super fast speeds. That the blades would have broken or failed to work without that trusty material, essentially rendering flight impossible.

The very stuff composing these turbine blades has gotten better and may further improve as the tech gets refined. Companies are continuously looking for new materials that can go even hotter and longer. They are also looking for lighter weight materials, which could reduce the amount of fuel that planes use while flying. Graphene and carbon nanotubes are just one of the futuristic, new material inside this category. These materials could one day help make planes both more efficient and safer.

Safety is a big concern when it comes to selecting the material for turbine blades of jet engine. If the material is wrong, it would be dangerous to use in flightautons. That is why the choice of material for jet engine production has a pivotal role in ensuring that they operate to specifications safely. There is a lot for comes to consider: How the material will be used in practice, cost of materials, blade performance and any safety concerns.

Jet engine turbine blades are manufactured from materials that must be able to withstand very highy and harsh conditions Those need to be able to withstand high temperatures, toxic gases and some really strong forces that come from spinning super duper fast. Blade Blur: Blade shape is also a high priority in the design process. It has to be streamlined, meaning shaped so as not to create any more drag than the plane experiences in flight.

Our company can provide customized services and is able to fabricate turbine components from an array of high-temperature alloys in accordance with the requirements of customers. No matter what jet engine turbine blades material, size or performance requirement, we can achieve it with our flexible production process and cutting-edge technology for process. We work closely with clients to comprehend their needs as well as the various scenarios they might encounter and give them professional assistance and suggestions. We have a variety of materials and processing capabilities to meet the unique requirements of different industries and applications. We aid our clients in improving their competitiveness on the market by offering custom-designed services that improve efficiency and lower costs.

Our company can fabricate highly precise and stable turbine parts through casting forging, and CNC machining. Casting allows us to create components with complex forms, high strength and long-lasting. Forging can give parts a more durable and superior mechanical property. CNC technology for machining, on other hand, ensures high precision and consistency of every part, which reduces the chance of the chance of errors and producing substandard products. Our technical team that constantly carries the latest technological advancements and process improvement to make sure that our products are always at the top of the industry in terms of jet engine turbine blades material. We're determined to meet our customers' demands for high-performance turbine components through continuous technological advancement.

Our customer support is jet engine turbine blades material and includes technical assistance, pre-sales advice and after-sales assistance to ensure our customers have the best possible experience. Our experienced team will review the needs of customers and offer the most effective solution and recommendations for the product. We provide technical support starting with the selection of products to installation and commissioning. This guarantees that our clients are able to enjoy our products without problems. We have a well-developed after-sales service that allows us to react quickly to customer requests and problems and provide quick and timely solutions. We strive to establish long-term relationships with our customers and earn their trust and respect by providing quality service.

Our company follows strict quality control standards to guarantee the best performance and dependability of each component The entire jet engine turbine blades material is monitored for quality starting from the purchase of raw materials all the way to the final test of the final product To ensure that the quality of our products is continually improved we regularly conduct audits and adjustments Our aim is to earn the trust and continue to work with of our customers by providing top-quality products and becoming an industry leader