Turbine Guide Vanes Turbine guide vanes are key parts of turbines. They regulate the inflow of air or gas to the turbine, ensuring its best performance and efficiency. At O.B.T, we know how valuable the best turbine guide vanes can be in industrial settings. Now, we will take a closer look at what these elements are and where you can acquire the best turbine guide vanes for your application.

Do you need the best industrial turbine guide vane for your processes? Then, look no further than partnering with an established and reliable manufacturer such as O.B.T. We have a team of professional engineers has been actively involved in developing and manufacturing superior turbine guide vanes for many years.

Apart from the material, the shape of turbine guide vanes also affects how well they perform. Our team at O.B.T are dedicated to empowering new and inventive designs which allow for the highest levels of performance from Turbine Guide Vanes, and deliver industries with superior efficiency in their operations.

In addition, manufacture processes being so accurate and precise play an extremely significant role in making excellent turbine guide vanes. Thanks to our cutting edge O.B.T technology and facilities we are able to guarantee precision when building turbine guide vanes in order that they can stand up even the most rigorous testing and data from our clients.

finding the best turbine guide vanes for your industrial applications is easy when you work with O.B.T. Dedicated to quality, innovation and client satisfaction, we strive to offer top-of-the-line turbine guide vanes that maximise your turbines’ performance. For all your turbine guide vane requirements go for O.B.T and feel the difference in performance and efficiency.

Guide vane of a turbine is a mandatory part of a turbine designed to regulate the flow of air or gas in a way that it minimize energy production. These vanes are arranged within the turbine in a manner that will cause the air or gas to be directed toward rotation rotor blades, and thus optimize efficiency. Operators are able to control the speed and pressure of the airflow by varying the angle of guide vanes, which leads to more efficient turbine operation. In a word, the guiding vanes are very important for making the turbine run as fast and efficiently as possible.

With the development of technology, several promising trends of a turbine guide vane are emerging. One important trend in this area is the growing use of more advanced materials that are both stronger and enable better end-of-life performance and efficiency, resulting in guide vanes that last longer while delivering improved performance. And more attention is being paid to intelligent technology and sensors in the turbine's guide vane that can monitor performance on line and adjust it as required. This drive towards digitalization and automation is transforming the design and operation of turbine guide vanes to more energy-efficient and dependable turbine systems.

Our company offers specific services that is able to manufacture turbine parts from various high-temperature alloys in order to satisfy the demands of customers. Our flexible production flow as well as our state-of-the-art process technology and our ability to satisfy particular requirements, like size and shape, as well as performance will allow us to meet every requirement. We are in constant contact with our customers in order to fully understand their needs specific to them and the application scenarios, and provide them with expert technical guidance and solutions. We have a rich selection of processing and materials that can meet the turbine guide vane of various sectors and application. Through customized services, we assist our customers in optimizing their product performance and cost, and improve market competitiveness.

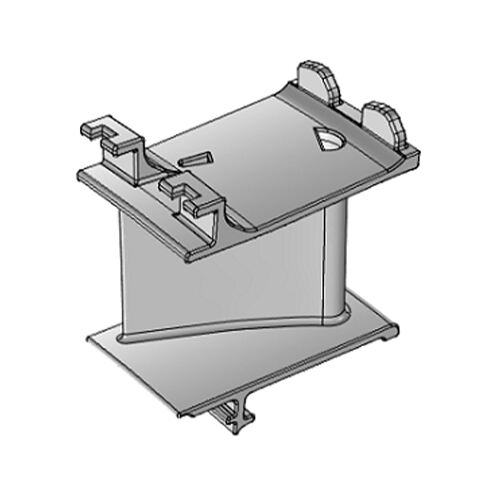

Our company has the ability to create highly precise and reliable turbine parts through casting turbine guide vane, and CNC machining processes. Casting allows us create components with complex designs, strong and long-lasting. Forging provides parts with a better mechanical quality and longer durability. CNC machining, on the contrary offers high precision and consistency for every component. This reduces errors and inferior products. Our technical staff is constantly developing technological advancements and process improvements to ensure our products are at the forefront of industry technology. We're committed to meeting our customers' demands for high-performance turbine components by continual technological advancement.

Our customer support is turbine guide vane and includes technical assistance, pre-sales advice and after-sales assistance to ensure our customers have the best possible experience. Our experienced team will review the needs of customers and offer the most effective solution and recommendations for the product. We provide technical support starting with the selection of products to installation and commissioning. This guarantees that our clients are able to enjoy our products without problems. We have a well-developed after-sales service that allows us to react quickly to customer requests and problems and provide quick and timely solutions. We strive to establish long-term relationships with our customers and earn their trust and respect by providing quality service.

We adhere to turbine guide vane of quality control in order to guarantee the performance and reliability of every component. Quality control is performed throughout the entire manufacturing process starting from the purchase of raw materials through the test of the finished product. In order to ensure that our product's quality is continuously improved, we also conduct regular audits and improvement. Our goal is to win the trust and cooperation of our clients by offering top quality products and to become a leader in the industry.