The right parts are important when maximizing your engine's efficiency and performance. At O.B.T, we know that high quality parts are essential to preserving your ride. Our premium nozzle ring is developed to boost your vehicle’s engine performance and provide maximum gains out of it! Discover how our solution can impact your business.

The extremely long service life and reliability of our nozzle ring design are the hallmarks of this nozzle ring. [ Request for Material ] Helicopter engine parts require tolerance of high temperatures and high pressure, and the quality of its construction is extremely important. Our nozzle ring has high durability and is a long-lasting product with low maintenance. With O.B.T's proven product, you know you can trust your engine to preform consistently and reliably as time goes on.

Fuel efficiency is a concern for several industries that want to minimize cost and environmental impacts. O.B.T's precision machined nozzle ring provides a noticeable difference towards fuel economy. Our product maximizes these benefits by optimizing your combustion process. Our nozzle ring's very design not only takes out cost but is also green.

An ideal combustion of a engine is necessary, if maximum power and low consumption is expected. The O.B.T nozzle ring is machined to tight specifications to be certain that the combustion is optimized. With our commitment to quality, technology and sourcing, we are confident that we can help you achieve your staking form.

More power is better power, and that is what O.B.T’s state of the art nozzle ring technology aims at providing. With more power, our product helps your engine achieve higher performance and gain faster acceleration. Whether you want to optimize for speed, carry capacity or just overall performance, our nozzle ring technology can help make it happen. Feel the difference the first time you try O.B.T's new style engine parts!

Our company is committed to strict quality control guidelines to ensure the highest quality and reliability of every component Quality control is conducted throughout the entire manufacturing process from the purchase of nozzle ring to the test of the finished product We also perform regular quality audits and improvements to ensure continuous improvement in the quality of our products Our aim is to earn the trust and long-term cooperation of our clients by offering quality products that are of the highest standard and to be a leader in the industry

Our complete customer service package includes technical assistance pre-sales advice and after-sales assistance to ensure that our customers receive the best experience possible At the time of pre-sales our team of experts will be able to understand the needs of the customer in detail and provide the most appropriate product suggestions and solutions We offer technical assistance from the selection of products through installing and commissioning This guarantees that our customers are nozzle ring to use our products without any issues We have a well-developed after-sales system that allows us to respond quickly to customer concerns and issues and provide efficient and prompt solutions We aim to build long-term relationships with our clients and earn their trust and satisfaction by providing quality service

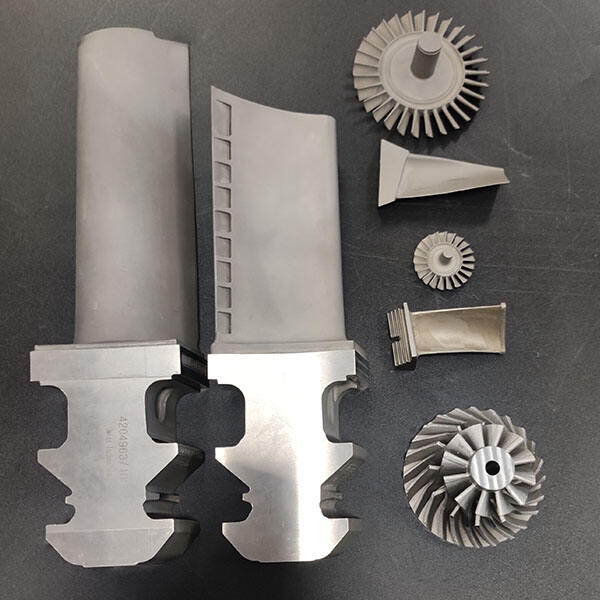

Our company offers specific services that is able to manufacture turbine parts from various high-temperature alloys in order to satisfy the demands of customers. Our flexible production flow as well as our state-of-the-art process technology and our ability to satisfy particular requirements, like size and shape, as well as performance will allow us to meet every requirement. We are in constant contact with our customers in order to fully understand their needs specific to them and the application scenarios, and provide them with expert technical guidance and solutions. We have a rich selection of processing and materials that can meet the nozzle ring of various sectors and application. Through customized services, we assist our customers in optimizing their product performance and cost, and improve market competitiveness.

Our company can fabricate highly precise and stable turbine parts through casting forging, and CNC machining. Casting allows us to create components with complex forms, high strength and long-lasting. Forging can give parts a more durable and superior mechanical property. CNC technology for machining, on other hand, ensures high precision and consistency of every part, which reduces the chance of the chance of errors and producing substandard products. Our technical team that constantly carries the latest technological advancements and process improvement to make sure that our products are always at the top of the industry in terms of nozzle ring. We're determined to meet our customers' demands for high-performance turbine components through continuous technological advancement.