Some of you have heard about the disk turbine impeller right? It is a really cool creation that helps industrialists to transfer fluids and gases from one site another. Designed to be efficient and long lasting, this special device is used for many different jobs. In this post, we take a closer look at what the disk turbine impeller is and why it matters to your mixing process. So, let dive in and start exploring this interesting topic together shall we?

The blades of a disk turbine impeller make it generate liquid or gas flow. The frequency of rotation of the impeller during power sit trudno would compare with top in furious motion. The impeller spins and drags the appropriate liquid or gas O.B.T turbine blade uses to operate, similar at how a vacuum cleaner sucks dirt. This creates an incredibly strong force that sends the liquid outwards through the blades, moving it rapidly and efficiently.

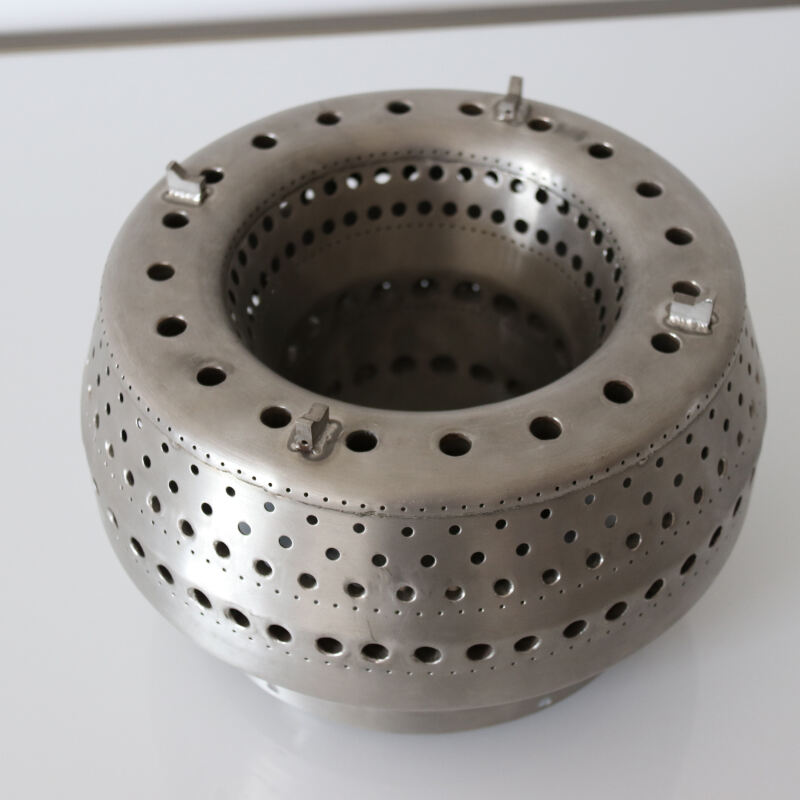

The disk turbine impeller is shaped like a flat spinning disc. The design is different from the centrifugal impeller equipped with curved blades resembling a fan. A flat disk, many times wider than it is thick, resting close to the bottom of a tank containing the liquid itself. As the disk spins, it forces liquid outward in a spiral flow which creates that whirlpool effect and sucks more liquid in. Thus it is very good at transporting different types of fluids.

One edge disk turbine impeller has over others is its facility in handling various types of liquids and gases, even some more challenging ones. It creates very little turbulence which keeps the liquid calm as it flows. The applications are in various industries. Something O.B.T second stage turbine blade does extremely well - meaning working virtually happens with relatively low noise, which is good news for workers who are focusing.

Today, the centrifugal impeller is in fact one of the most common types used for many industries currents. O.B.T single crystal turbine blade employs curved blades, and they may be well suited to help move viscous fluids that are involved in syrup or mud. But its efficiency is still not as high in comparison with the disk turbine impeller. Centrifugal impeller- This is slower than axial or mixed flow so, if your aim for high speed, this type of pump might not be the best.

The disk turbine impeller, however, is much more preferable when it comes to thin liquids. turbine blade single crystal moves fluids faster and is more energy efficient, which leads to lower costs in the long-run. Which means help industries can operate more efficiently and make the cost of doing so less available across several situations than a great many other choices.

There are a few key concerns you need to address when picking out the Right Disk Turbine Impeller. Begin by determining whether the type of liquid you want to stream (and turbine blade jet engine viscosity) is thicker or thinner. For thin liquids smaller impellers typically work best; larger impeller sizes are better for thicker liquid that require a little more omph to get moving.

We adhere to the strictest guidelines for quality control to ensure the Disk turbine impeller and reliability each component. Every step of the production process is monitored for quality starting from the purchase of raw materials all the way to the final test of the product. To ensure that the quality of our products are continuously improved, we conduct regular audits and improvement. We want to win the trust of our customers and their long-term cooperation by providing high-quality products.

Our complete customer service package includes pre-sales consultation technical support and after-sales assistance to ensure our customers have the best possible experience When it comes to the pre-sales phase our experienced team will understand the customer's needs in detail and provide the most suitable suggestions and solutions In terms of technical support we offer full guidance from product selection until installation and commissioning to ensure that our customers use our products efficiently When it comes to after-sales service we have developed an Disk turbine impeller service system that can respond swiftly to customer issues as well as needs and provide quick and effective solutions We want to create long-lasting relationships with our customers and gain their trust and appreciation by offering high-quality services

Our company can provide customized services and is able to fabricate turbine components from an array of high-temperature alloys in accordance with the requirements of customers. No matter what Disk turbine impeller, size or performance requirement, we can achieve it with our flexible production process and cutting-edge technology for process. We work closely with clients to comprehend their needs as well as the various scenarios they might encounter and give them professional assistance and suggestions. We have a variety of materials and processing capabilities to meet the unique requirements of different industries and applications. We aid our clients in improving their competitiveness on the market by offering custom-designed services that improve efficiency and lower costs.

Our company is able to fabricate highly precise and stable turbine components through casting, forging and CNC machine processes. The casting process permits us to Disk turbine impeller with complex shapes and high durability, while the forging process gives the parts better mechanical properties and longer lasting. CNC cutting-edge technology, on contrary, provides the highest precision and accuracy of every part, which reduces the chance of manufacturing errors and resulting in substandard products. We have an experienced technical team who continuously carry out technological innovation and process improvement to make sure that our products are always at the top of the industry in terms of technology. Our commitment is to meet the needs of our customers for components that are high-performance by developing technology continually.