Let us first start with the significance of turbochargers in engines. They help enhance engines to grow stronger and perform better. How do they do this? Turbocharger systemTurbos do this by compressing the air that enters the engine. This causes the air to become denser as it is compressed. The denser air mixes more easily with the fuel in the motor, which means it can combust better. turbine blade designs The engine is being given additional energy with this burning. The nozzle ring is one of the main elements that meet this need and allow turbos to operate effectively. Nozzle rings are a small part that has a big effect on the operation of turbochargers.

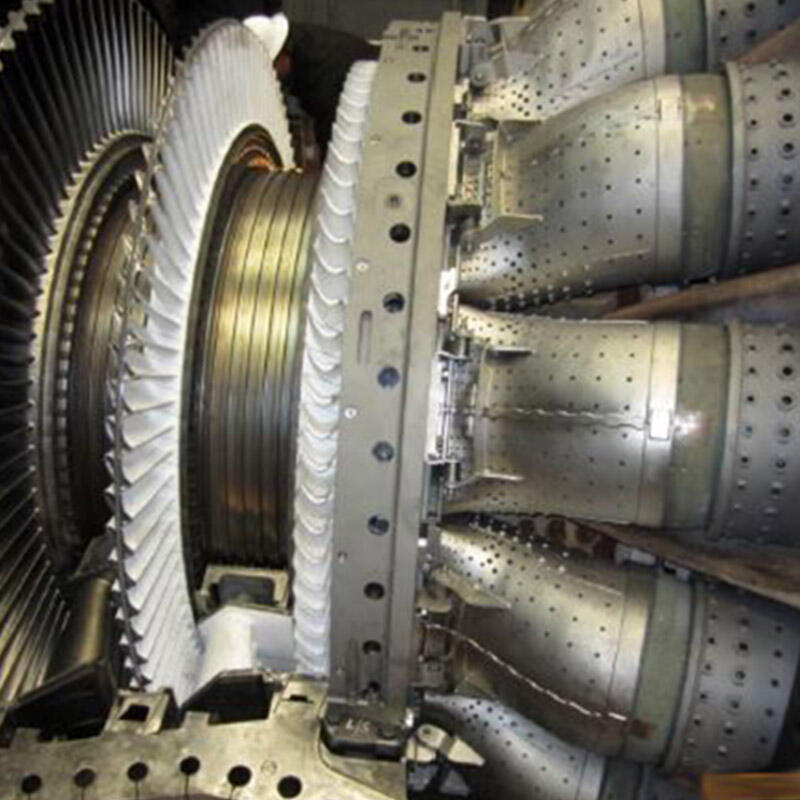

Nozzle rings are situated at the end of a component known as the turbine housing. Their role is to direct the exhaust gases exiting the turbine. The engine consumes fuel, and it produces exhaust gases. These gases have to exit from the engine properly. These exhaust gases are then channeled using nozzle rings towards the turbine blades. The exhaust gases push against these blades and make them rotate. This spinning motion is crucial because it powers another component, the compressor wheel. The compressor wheel inhales more air, then is compressed to generate more horsepower. This creates a cycle where the compressed air that enters the engine increases the power and torque of the vehicle.

For the optimum operating efficiency of a turbo charger, the nozzle rings play a major role. By diverting exhaust gases, they ensure that only the optimal amount of energy spins the turbine blades. A turbocharger operates to an efficiency value known as pressure ratio. turbine blade design This ratio indicates the capability of the turbocharger providing air to the engine. More pressure ratio more oxygen moving through the compressor more power from the engine.

Performances of turbochargers alter owing to the distinctive patterns of nozzle rings in its design. The nozzle ring has an important role in directing the flow of the exhaust gases due to its shape and dimension. Smaller and with a larger angle turbine blade nozzles ring are used to increase the turbocharger pressure ratio. However, large nozzle rings with a smaller opening angle actually decrease the pressure ratio. It is important to recognise these various configurations to select the correct Ring for each turbo arrangement.

Another function that nozzle rings are vital to is the control of the flow of exhaust gasses in a turbocharger. They are important in making sure that the exhaust gases leave the turbine at the correct angle and direction. This is crucial due to the fact that the gases need to exit properly otherwise, it will backflow or create turbulence. the second stage turbine blade So it can reduce the efficiency of the turbocharger. Expansion nozzle rings also aid in maintaining turbine blade temperatures. Proper cooling of the blades prevents damage or wear to the turbine itself which can help the turbocharger last longer and function more efficiently overall.

Turbo nozzles ring selection is an extremely important task. The nozzle ring itself plays a pretty large role in how well a turbo operates. Different kinds of nozzle rings are designed for different engine sizes and applications. gas turbine blade The size of the engine, its intended use, and the level of power desired must all be taken into account when choosing a nozzle ring. Considering these points will aid you in the good selection of nozzle ring unit.

O.B.T has a variety of nozzle ring options designed and custom manufactured to fit most turbocharger applications. Our nozzle rings are manufactured from high-quality materials and are subjected to stringent testing to ensure reliability in performance. steam turbine blade If you are looking for a solution to drive valves, in accordance with the specific requirement of our customer, we also ensure appropriate nozzle ring for your turbocharger setup.

Our company adheres to strict quality standards to ensure the highest quality and the reliability of every component Quality control is carried out throughout the entire process of production from the acquisition of raw materials to the testing of the final product We also perform regular quality Nozzle ring used in turbocharge and adjustments to ensure constant improvements in product quality Our goal is to win the trust and long-term cooperation of our clients by offering high-quality products and to become a leader in the industry

Our company offers a variety of customized services, and produces turbine components from an array of high-temperature Nozzle ring used in turbocharge to meet the requirements of our customers. Our flexible production process and advanced technology for processing and our ability to satisfy specific requirements, such as size shape, performance, or shape, allows us to achieve every need. We communicate closely with our customers in order to fully understand their individual requirements and situations and offer expert advice and solutions. We offer a wide range of materials and processing capabilities to meet the specific demands of various industries and applications. Through customized services, we help our customers optimize product performance and efficiency and increase competitiveness in the market.

Our comprehensive customer service includes pre-sales consulting technical support and after-sales services to ensure that customers enjoy the most enjoyable experience Our expert team will assess the needs of customers and offer appropriate product suggestions and solutions We provide technical support starting with the selection of products through installation and commissioning This ensures that our customers are able to enjoy our products without issues For after-sales support we have developed an efficient service system that can respond swiftly to customer issues as well as needs and provide Nozzle ring used in turbocharge and efficient solutions Our goal is to create long-term relationships and gain customers trust and their satisfaction by providing superior customer service

Our company is able create highly precise and reliable Nozzle ring used in turbocharge by using casting, forging and CNC machine processes. Casting allows us to make parts with complicated designs, strong and long-lasting. Forging gives parts a higher mechanical property and durability. CNC technology for machining, on other hand, ensures an extremely high level of precision and consistency in each component, thus reducing the risk of manufacturing errors and resulting in substandard products. Our technical staff is constantly striving to improve technological innovation and process improvements to ensure that our products remain at the leading edge of industry technology. We're committed to meeting the demands of our customers for high-performance turbine parts through constant technological advancement.