Analyzing Jet Engine Turbine Disk A jet engine turbine disk is one of those aero engines parts which are vital for the working of the airplane. This will be a circular disk which is created from materials of very high tensile strength such as titanium or some kind of special nickel. That disc is attached to a rotating spindle that spins very quickly — sometimes up to 15,000 times every single minute. That's an alarmingly high velocity

A disk is hollow and that there is nothing inside it. These O.B.T jet engine compressor blade material are actually blades sticking out on the outer edge of the disk. This air is forced against the blades when it comes into the engine, which in return start spinning really quickly. The spinning motion generates tons of power — enough that it runs other things on the plane, like the generator (which makes electricity) or even a hydraulic system that helps raise and lower the wings.

The turbine disk in a jet engine spins very fast, and because it is so hot. Spinning blades can generate quite a pocket of heat due to the friction with air. In order to prevent the disk from overheating and becoming damaged, it has specialized cooling holes built in. These holes allow the air to circulate inside the disk providing a means for cold air to enter and hot air from within to escape, allowing the disc not overheat

How the blades are connected to the disk is also crucial. But they aren't simply glued or screwed in place as you might expect, instead they are fit together using a unique method know as dovetailing. That is to say, little slots are created on disk and blades too which can sit close with each other similar to 2 elements of puzzle. The whole setup is a very strong bond, which will be able to resist the high speed and temperature produced as the disk runs with the engine running.

Being that the O.B.T jet engine turbine blade is such a critical element to keep planes in the air, it needs to work perfectly all the time. Technicians routinely check it in order to ensure that it is functioning properly. During these inspections, they search for any type of issue with the disk or blades whether damage or misuse. They also check the cooling holes, and every other part in the engine for making sure all its functionality are going nice.

Using new materials and manufacturing methods is a second, more ambitious approach to making the jet engine turbine disk safe. Businesses such as O.B.T are consistently investigating new and improved materials to provide better results of producing the most efficient, high-integrity jet engine turbine disks on the planet. This new development will enable aircraft to fly farther, faster and above all safer than ever before.

With the rate of technology increasing, we have a lot to look forward to with future jet engine turbine disks. A cool feature is the O.B.T turbine blade jet engine have the ability to produce special disks that are made specifically for some engines using 3D printing tech too. The technology was unique in that it allowed engineers to generate unusual and complex shapes, shapes difficult—if not impossible—to produce through traditional means of manufacture.

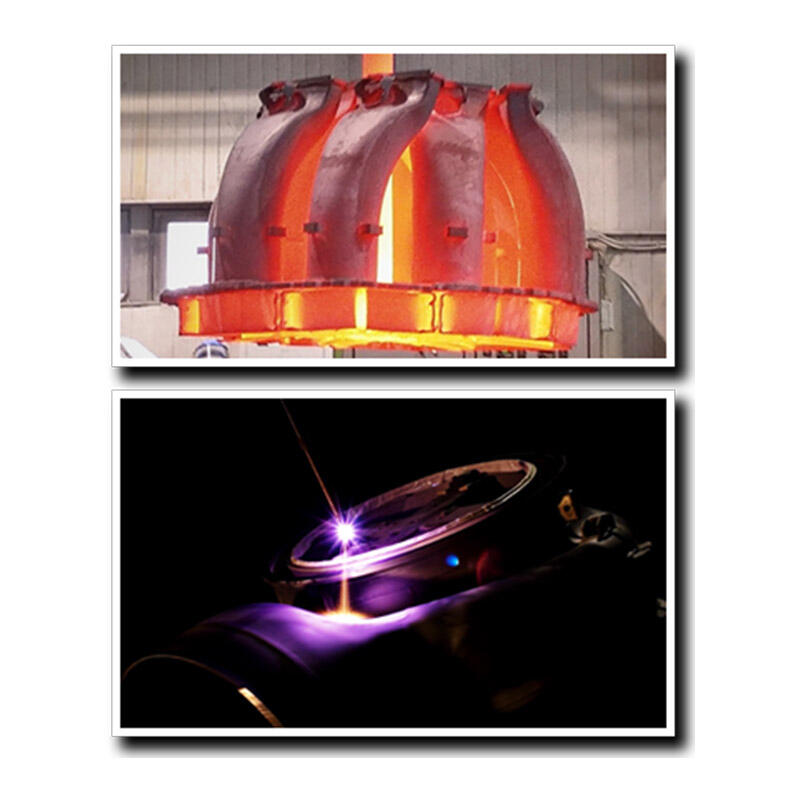

We are able to create turbine components with high accuracy and consistency using CNC casting, machining and forging processes. Casting allows us create parts with Jet engine turbine disk, strong and durability. Forging offers parts more durable and superior mechanical property. CNC machining, on the contrary is extremely precise and consistency for each part. This eliminates mistakes and poor quality products. Our experienced technical team is continuously researching technological advances and process optimizations in order to keep our products at the leading edge of industry technology. We're committed to meeting the demands of our customers for high-performance turbine components by the continuous advancement of technology.

We adhere to the strictest guidelines for quality control to ensure the Jet engine turbine disk and reliability each component. Every step of the production process is monitored for quality starting from the purchase of raw materials all the way to the final test of the product. To ensure that the quality of our products are continuously improved, we conduct regular audits and improvement. We want to win the trust of our customers and their long-term cooperation by providing high-quality products.

We offer comprehensive customer support that includes pre-sales consultation technical support as well as after-sales services to ensure that our customers have the best possible experience When it comes to the pre-sales phase our team of experts will be able to understand the needs of the customer in detail and provide the most appropriate product suggestions and solutions For technical support we offer complete guidance from selecting the product to installation and commissioning to ensure that our customers use our products without difficulty For after-sales support We have created an efficient service system that can respond swiftly to customer issues and requirements and offer prompt and effective solutions We aim to build long-term relationships with our customers and earn their Jet engine turbine disk and respect by providing quality service

Our company offers customized services and is able to fabricate turbine components from many different high temperature alloys based on customer specifications. Our flexible production flow along with our advanced process technology and our capability to meet Jet engine turbine disk, such as size and shape, as well as performance can allow us to meet any requirement. We work closely with clients to comprehend their needs and the potential scenarios for their applications, and then give them professional guidance and solutions. Our wide range of products processing capabilities, processing capabilities, and specific requirements for applications allow us to fulfill the particular requirements of various industries and application. With our customized services, we help our customers optimize efficiency and costs of their products, and improve market competitiveness.