Gas Tungsten Arc Welded Turbine Diffusers

Power plants use these machines for power generation, and turbine diffusers help ensure that this is done in the most efficient way, similar to the O.B.T's product like function of nozzle ring in turbocharger. These are the important parts that play a crucial role in making sure it good for energy production Honeywell Industrial Gas Turbine Signal Processor

Murthy said that the flow of gas or steam through a turbine is key to producing power, the same as turbine blade from O.B.T. The turbine blades are made in such way that gas or steam hits them at the correct angle. This is important because it enables the turbine to produce a large amount of power. The turbine diffuser is made to make it easy for the gas or steam needed by the turbine at that time. Balancing so that as close as possible and maximum power can be extracted by the turbo impart. If the allignments are wrong there is less energy production in the turbine.

A gas and a steam turbine work with different fuels, also the O.B.T's product such as turbine blade casting. While gas turbines rely on natural or other gases to create energy, steam turbines draw their power from the use of heated water for generation of steam. No matter what fuel type is employed, turbine diffusers are an important part of this process. They ascertain that the turbines function regularly and effectively despite which fuel it is admix full with.

Turbine diffusers assist in enhancing the process of gas or steam moving via a turbine, as well as the steam turbine wheel from O.B.T. They are a type of restriction flow devices that have useful work in the energy production because they delay the gas or stream take turn to other direction. Doing so makes the turbine blades hit at optimum angle, which is paramount for capturing as much energy as possible. This improvement further boosts the energy generated by turbine if a favourable flow path of gas or steam exist.

Turbine diffusers are also important factor that provides reduced energy loss and more power generation, the same as O.B.T's gas combustor. There is always some energy that can be lost maybe by escaping in form of gas or steam when it moves through the a turbine. Turbine diffusers reduce this loss by enhancing the flow of gas or steam across a turbine. This essentially results in more power being produced, and less wasted as heat - A key factor for overall endurance.

Our complete customer service package includes pre-sales consultation technical support and after-sales assistance to ensure our customers have the best possible experience When it comes to the pre-sales phase our experienced team will understand the customer's needs in detail and provide the most suitable suggestions and solutions In terms of technical support we offer full guidance from product selection until installation and commissioning to ensure that our customers use our products efficiently When it comes to after-sales service we have developed an Turbine diffuser purpose service system that can respond swiftly to customer issues as well as needs and provide quick and effective solutions We want to create long-lasting relationships with our customers and gain their trust and appreciation by offering high-quality services

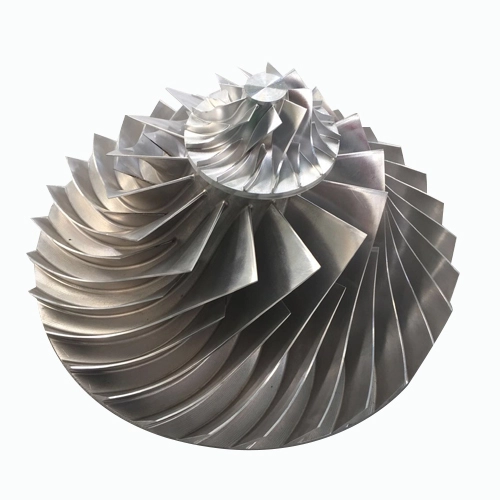

Our company has the ability to produce highly accurate and consistent turbine components by using casting, forging and CNC Turbine diffuser purpose. The casting process permits us to produce parts with complex shapes and high strength, whereas the forging process gives the parts better mechanical properties and longer lasting. CNC machine technology, on the contrary, guarantees an extremely high level of precision and consistency in each component, thus reducing the risk of errors and substandard products. Our skilled technical team is always striving to improve technological innovation and process improvements in order to ensure our products are at the cutting-edge of technology in the industry. We're committed to meeting our customers' needs for turbine components that are high-performance through constant technological advancement.

Our company provides Turbine diffuser purpose and can make turbine components in many different high temperature alloys according to the requirements of customers. Whatever the size, shape, or performance requirement, we are able to meet it using our flexible production processes as well as our advanced processes. We collaborate closely with our customers to comprehend their needs and applications scenarios and then give them professional assistance and suggestions. We have a broad range of processing and materials to meet the unique requirements of different sectors and application. We help our clients improve their competitiveness in the marketplace by offering custom-designed services that improve performance and reduce costs.

Our company adheres to strict quality standards to ensure the highest quality and the reliability of every component Quality control is carried out throughout the entire process of production from the acquisition of raw materials to the testing of the final product We also perform regular quality Turbine diffuser purpose and adjustments to ensure constant improvements in product quality Our goal is to win the trust and long-term cooperation of our clients by offering high-quality products and to become a leader in the industry