What is a compressor impeller? It is almost like you are blowing air through a pipe, but really hard and super fast… kind of how it feels when riding on rollercoasters! When you are on a rollercoaster imagine the air speeding past your face, giving you an adrenaline feeling. It is, just as how air responds to a spinning compressor impeller!

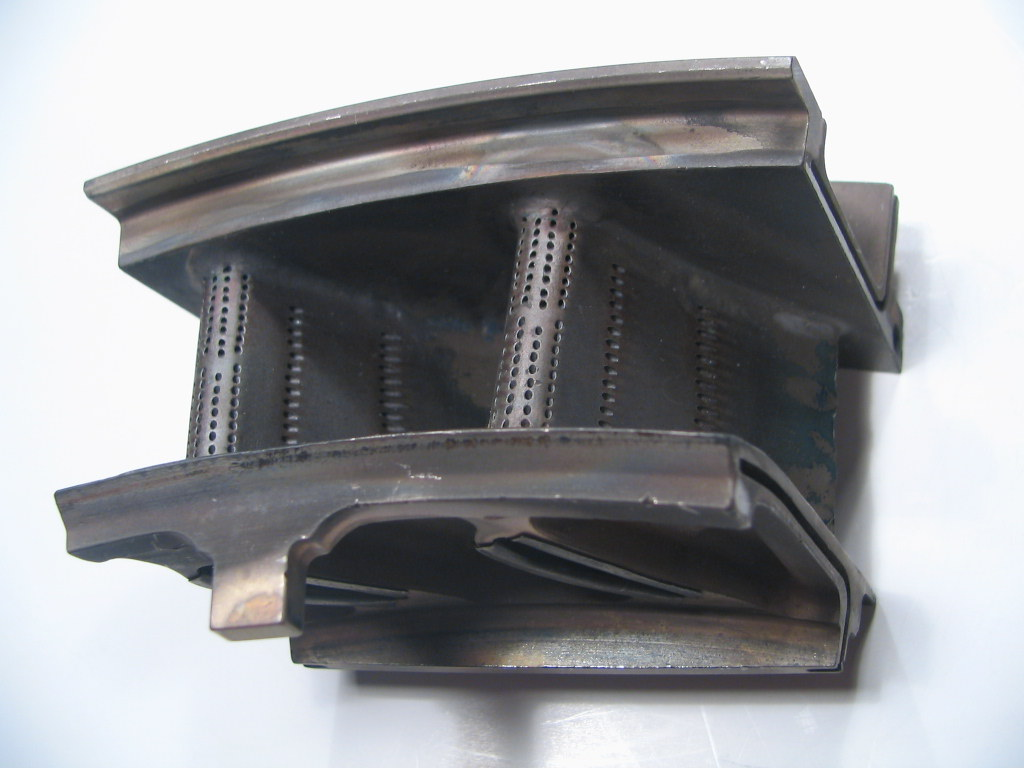

A compressor impeller is like a fan with many blades that spins extremely fast. These blades are crucial to driving the air. How fast it spins depends on the design of an impellerthe engineers sort out that gets really kind of complicated like a secret recipe to make everything work perfectly. Various designs can be used to make the impeller spin more quickly or slowly as needed. In some cases, the impeller is enclosed in a duct to benefit with air direction. When it sends the air through this tube, by contrast, on the opposite side of that valve...NOW!!!.ready to perform.

The compressor impeller needed to be designed for the best efficiency engineers could find. This means they want it to almost use of the energy so that the impeller can do its best superhero impression! Has the impeller has to be good because should let through air freely. Leakages or blockages can prevent efficiently o change is blocked, and engineers have to determine whether there are any of these. It is very useful for impeller, as in air conditioner or refrigerator and some cars too! When the impeller works properly it keeps this machines providing cool and fresh.

For a superhero to get the job done, they usually need some muscle; likewise for compressor impellers. As a result it must be strong and durable, will not crack under pressure for at least one hundred uses. So engineers have to use special materials in the impeller so it doesn't fly apart when spinning that quickly. It also makes sure that each and everything of the impeller to be durable for a longer period as it can able to bear high pressure up on. This durability is crucial since this indicates the impeller would keep on working w/o ending it b/c of destruction

Engineers Consider Many Materials When Making a Compressor Impeller In such application, they will probably be using strong metals like Aluminum or Steel because when a force passes through the load cell these materials can easily manage it. This force is applied with a few high-tech plastics that they use as well. Thus, engineers need to choose the most suitable one for that application and Impellers which are made out of those different materials have their good points and bad points. They will often combine or meld different materials together, improving an already strong mix of substances to fit the purpose even better! And so doing the proper legwork in choosing materials also helps ensure that whatever impeller you have can do its job efficiently over a number of years.

Did you ever hear of the roar of apparatus? That can sometimes be when the compressor impeller is rotating at speeds of, like...gazillions. It can be irritating and distracting when trying to rest or focus. However, engineers are exploring how to make the impeller quieter and less likely to get stuck on its axis. They can also locally alter its design, such as changing the size and shape of the blades to reduce not only noise but vibrations that it may assemble. This is crucial for devices that people are likely to use on a daily basis, like air-conditioning units and cars because the hope is they would be relatively quiet when operating in the background.

We are able to create turbine components with high accuracy and consistent quality through CNC machining, casting and forging processes. Casting allows us to create parts with complex shapes, high strength and long-lasting. Forging can give parts a more durable and superior mechanical property. CNC compressor impeller design technology, on other hand, ensures the highest precision and accuracy of each piece, minimizing mistakes and ensuring that the product is of a high standard. Our highly skilled technical team is continuously developing technological advancements and process optimizations in order to keep our products at the cutting-edge of technology in the industry. Our commitment is to meet the needs of our customers for components that are high-performance by developing technology continuously.

Our company offers customized services and is able to fabricate turbine components from many different high temperature alloys based on customer specifications. Our flexible production flow along with our advanced process technology and our capability to meet compressor impeller design, such as size and shape, as well as performance can allow us to meet any requirement. We work closely with clients to comprehend their needs and the potential scenarios for their applications, and then give them professional guidance and solutions. Our wide range of products processing capabilities, processing capabilities, and specific requirements for applications allow us to fulfill the particular requirements of various industries and application. With our customized services, we help our customers optimize efficiency and costs of their products, and improve market competitiveness.

Our comprehensive customer service includes pre-sales consulting technical support and after-sales services to ensure that customers enjoy the most enjoyable experience Our expert team will assess the needs of customers and offer appropriate product suggestions and solutions We provide technical support starting with the selection of products through installation and commissioning This ensures that our customers are able to enjoy our products without issues For after-sales support we have developed an efficient service system that can respond swiftly to customer issues as well as needs and provide compressor impeller design and efficient solutions Our goal is to create long-term relationships and gain customers trust and their satisfaction by providing superior customer service

We follow compressor impeller design for quality control to ensure the performance and reliability of every component. The entire process of production is subject to quality control, from the raw material purchase until the final testing of the product. We also regularly conduct quality audits and improvements to ensure continuous improvement of product quality. We are determined to gain the trust of our clients and to maintain their long-term relationship by offering high-quality products.