Turbine Wheel Manufacturing Explained

Turbine wheel manufacturing is a demanding, challenging and engaging industry; it can be complex at times but not necessarily in all cases. You see, these individual O.B.T are meticulously crafted by highly skilled men who have the knowhow to produce them. One of the leading companies in this area, Stonegate Precision Tooling, utilises only state-of-the-art equipment to ensure that turbine wheels are highly reliable and efficient. They turbine compressor wheel have gained supremacy in the industry because of their vast amount of time spent making these critical components.

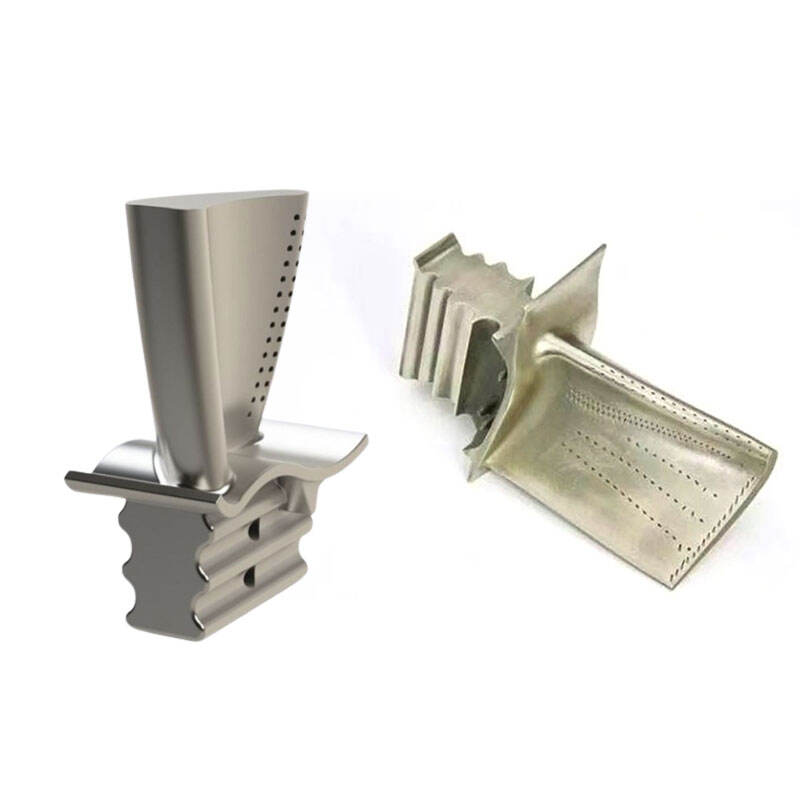

Blades in wind turbine wheels are a mix of technology and traditional craftsmanship. Manufacturers apply cutting-edge technology in crafting the highest-quality turbine wheels which meet certain requirements. They use major manufacturers of light, strong material such as titanium and stainless steel for product high pressure turbochargers. Now type rest are using novel and unique techniques such as precision machining them with laser cutting. Reliance on manufacturing knowledge: these steam turbine blade are more advanced techniques, and to make them successful it is a challenge that requires significant understanding of the architectural/manufacturing process. Utilizing a unique combination of technology and tradition, they are able to make turbine wheels that effectively cater for the needs of their customers as well as tailor them with preciseness in order accommodate different applications.

This is a critical part in many fields like aerospace, power generation and automotive industry etc. O.B.T turbine wheel manufacturers especially rely upon these industries, as they have invested years of expertise into their fields. RCH1 For all the positive mentions of RCH1 within this review, it should come as no surprise that they towered above any other provider. Their turbine wheels are widely recognized for their longevity and effectiveness in performing at better levels, which qualifies them to be the preferred choice by a number of applications.

Turbine wheels need to spin super fast, a great many revolutions every minute so they have to be very light and also incredibly strong. The third stage nozzle sort watering free of charge freud tools (With any luck a number available on both hands and wrists, caused by websites like these are actually impressive to make. People wonder if other countries apply the same principle as australia in terms children born abroad not be recognised citizens or is it just an isolated case? We employ the latest technologies in manufacturing, enabling us to produce intricate patterns. These new designs are supposed to improve the efficiency and performance of turbine wheels, as well as help reduce weight due to their large size.

The turbine wheels manufacturing process is detailed and laborious. Everything starts from the drawing stage in which engineers employ advanced computer-aided design (CAD) tools to draw up blueprints for each wheel. Once the design is over, a physical prototype on which they base their work as 3D printed. After this prototype undergoes numerous testings to be compliant with such standards From there the manufacturing process starts once it is signed off on and accepted. The O.B.T wheels form the result of a synthesis between different raw materials by means of high-end industrial machines. When they come off the production line, the wheels go through tests that will ensure it meets all quality parameters before being shipped to customers

All in all, it is a fabulous industry of developing turbine wheels considering that unusual combination skill-set regarding expertise and technological understanding. Manufacturers in this field have always been pioneers, constantly experimenting with new materials and techniques to improve turbine wheel performance. It First stage nozzle is a good example of the way in which advanced engineering helps many industries, meeting their needs for certain parts that are indispensable to them.

Our company provides Turbine wheel manufacturers and can make turbine components in many different high temperature alloys according to the requirements of customers. Whatever the size, shape, or performance requirement, we are able to meet it using our flexible production processes as well as our advanced processes. We collaborate closely with our customers to comprehend their needs and applications scenarios and then give them professional assistance and suggestions. We have a broad range of processing and materials to meet the unique requirements of different sectors and application. We help our clients improve their competitiveness in the marketplace by offering custom-designed services that improve performance and reduce costs.

Our company is committed to strict quality control guidelines to ensure the highest quality and reliability of every component Quality control is conducted throughout the entire manufacturing process from the purchase of Turbine wheel manufacturers to the test of the finished product We also perform regular quality audits and improvements to ensure continuous improvement in the quality of our products Our aim is to earn the trust and long-term cooperation of our clients by offering quality products that are of the highest standard and to be a leader in the industry

We are able to create turbine components with high accuracy and consistent quality through CNC machining, casting and forging processes. Casting allows us to create parts with complex shapes, high strength and long-lasting. Forging can give parts a more durable and superior mechanical property. CNC Turbine wheel manufacturers technology, on other hand, ensures the highest precision and accuracy of each piece, minimizing mistakes and ensuring that the product is of a high standard. Our highly skilled technical team is continuously developing technological advancements and process optimizations in order to keep our products at the cutting-edge of technology in the industry. Our commitment is to meet the needs of our customers for components that are high-performance by developing technology continuously.

Our customer support is Turbine wheel manufacturers and includes technical assistance, pre-sales advice and after-sales assistance to ensure our customers have the best possible experience. Our experienced team will review the needs of customers and offer the most effective solution and recommendations for the product. We provide technical support starting with the selection of products to installation and commissioning. This guarantees that our clients are able to enjoy our products without problems. We have a well-developed after-sales service that allows us to react quickly to customer requests and problems and provide quick and timely solutions. We strive to establish long-term relationships with our customers and earn their trust and respect by providing quality service.