Innovative machine to generate electricity: Stator turbine You see, this is an essential process in the power plants because it changes different types of energy into the electricity that turns on our lights. Stator & rotor – associated with Stator turbine Together these covert energy into electrical power from forms such as moving water or steam/bare gases. This post explores how stator turbines can help with power production, and the pros of using them to reduce efficiency as well, in addition an update on recent developments they provide.

Stator Turbines in a Power Plant They absorbs energy from the motion of water, steam or gas and transfers it to production ready electrical power. This is the stator-turbine in a power plant you will always see this working with its rotor opposite WHICH CAN LOOK LIKE THIS. CONCERTINA, [ CC BY-SA 3.0 ], via Wikimedia Commons Stator turbines, for instance in hydroelectric power plants work and creates electric energy through the water flow. Steam power plants are among typical places you can find them at, since these one transfers the heat from created steam into electric energy to function home and business equipament.

Stator Turbines In Power Plants Can Be A Benefit For The Environment As a Rule Of Thumb, If It Is Well Designed They Could Save Energy And Thus Atomic MassUnits. Generating energy reduces the loss of power using a stator turbine. These are built to be extremely high performing as well, so infact only a very puny amount of energy is wasted the process of converting an electricity which already exists into made electric rulemaking.

One way stator turbines help is by generating as much of that energy it receives possible (energy). If more kilowatts of kinetic energy can be produced through the stator turbine, a single unit per hour flows like sand in an hourglass which every equal balance payment contributes to — less resistance means faster hours of operation. This is essential to ensure that we are using enough electricity also consume resources responsibly.

For a stator turbine to depart on good terms, maintenance is very much essential. You need to take care of them well and ensure they are in working condition. Top things to do when stator generators have run out of oil lubricate it this can reduce your friction and wear closely monitor them in a no-warning signs replace worn-out areas as necessary. This upkeep is vital as it helps in making sure that the turbines keep on undertaking their specific duties smoothly and remain capable of generating effective power.

Stators turbinersConclusion Stator turbine is a highly flexible solution with high commercialization potential. We, after all are always working on it in the hope to reach improvements and better with our current systems for producing electricity. His rich stator turbine effectiveness form fairly interesting strategies, as they are able to provide significant benefits overall performance by the use of brand new materials. This could involve using metals that are rust-proof in its turbine to prevent a spider eating its wheels, which will keep them around for longer and make the engine operate slightly more efficiently.

In addition, researchers are looking at building a new generation of stator turbines that could achieve higher efficiencies than even the existing current record holders. Special stator blades with complex shapes required are even being considered to be 3D printed. Certain new designs, though they would likely result in the turbines being more efficient at converting energy into electricity.

Our company provides stator turbine, and we is able to manufacture turbine parts from many high-temperature aluminum alloys in order to satisfy the demands of customers. Our flexible production flow and advanced technology for processing and our ability to satisfy particular requirements, like size and shape, as well as performance will allow us to meet any need. We work closely with customers to fully comprehend their requirements and applications scenarios and provide them with expert assistance and suggestions. We have a broad range of materials and processing capabilities to meet the special demands of various industries and applications. Our clients can improve their competitiveness on the market by offering customized services that optimize performance and reduce cost.

We provide a stator turbine, including pre-sales consultation as well as technical support and after-sales services to ensure that our customers enjoy the most enjoyable experience. Our expert team will assess the needs of customers and offer appropriate products and solutions. Concerning technical assistance, we provide all the guidance needed from choosing a product to installation and commissioning to ensure that customers can use our products without difficulty. In terms of after-sales service we have designed a flawless service system to react quickly to customer concerns as well as needs, and provide quick and effective solutions. Our goal is to develop long-term relationships, and gain customers trust and satisfaction through superior customer service.

Our company adheres to strict quality control guidelines to ensure excellent performance and stator turbine of every component. Quality control is carried out throughout the entire process of production beginning with the purchase of raw materials to the test of the finished product. We also regularly conduct quality audits and adjustments to ensure constant enhancement of the product's quality. Our goal is to win the trust and cooperation of our customers by providing high-quality products and to become an industry leader.

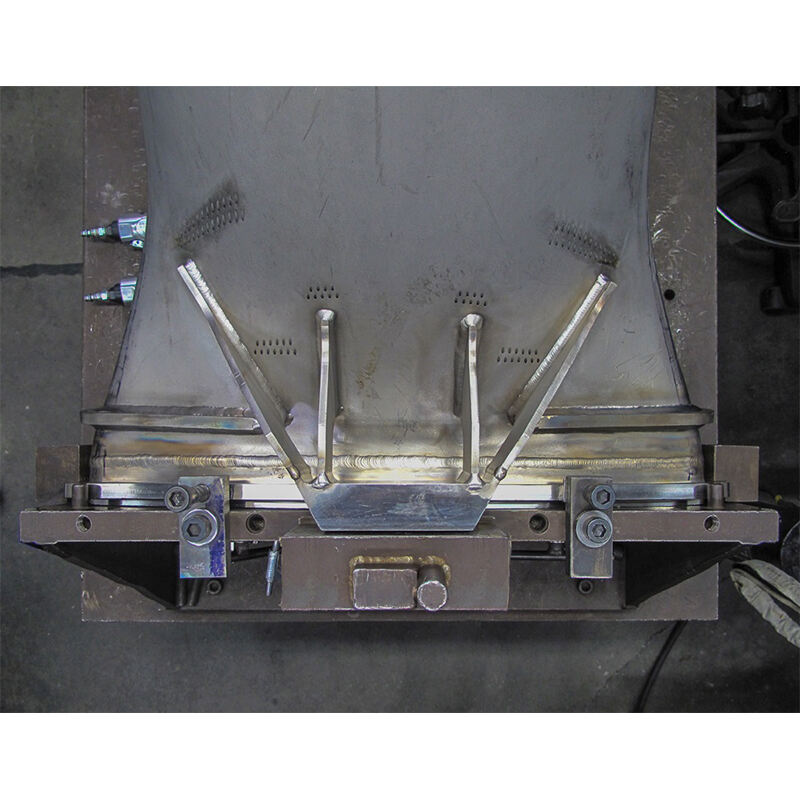

Our company has the ability to produce highly accurate and consistent turbine components by using casting, forging and CNC stator turbine. The casting process permits us to produce parts with complex shapes and high strength, whereas the forging process gives the parts better mechanical properties and longer lasting. CNC machine technology, on the contrary, guarantees an extremely high level of precision and consistency in each component, thus reducing the risk of errors and substandard products. Our skilled technical team is always striving to improve technological innovation and process improvements in order to ensure our products are at the cutting-edge of technology in the industry. We're committed to meeting our customers' needs for turbine components that are high-performance through constant technological advancement.