ОБТ чини напоре за побољшање моторних гасних турбина како би постигао њихове најбоље перформансе. Метода на коју то радимо је кроз нешто што се описује као дифузер. Дифузер је посебан елемент који успорава ваздух или гас који иде у мотор и шири га. Овај начин процеса омогућава мотору да користи ваздух или гас ефикаснијим начином. У моторма са гасовим турбинама, дифузор се често налази на улазу (предњем делу мотора) како би успорио и дифузио ваздух пре уласка у мотор.

Има много предности које долази са ОБТ-ом. дифузер у моторма са гасовинским турбинама - Да ли је то истина? Прво, помаже да мотор функционише много ефикасније тако што омогућава да ваш мотор добија више снаге из ваздуха или гаса који у њега тече. То значи да мотор може да користи исто гориво, али производи више снаге. То омогућава компанијама да уштеде новац и остваре већи профит док добијају више енергије без потребе за горивом.

Такође, дифузорска технологија може помоћи у побољшању способности гасних турбинских мотора да реагују на промене у свом окружењу. Будући да су ови мотори под (теоретским) директнијим људским надзором / негу, ако се услове око мотора промене - тј. температуре или количина доступног ваздуха или однос мешавине горива итд. - онда процес прилагођавања може бити лакши. Као резултат тога, мотори су у стању да испоруче ефикасне картице које раде у изазовним условима или док се суочавају са сложеним проблемима.

Још једна највећа предност дифузерске технологије је да може минимизирати загађење које ослобађају мотори са гасовим турбинама. ОБТ је заиста забринут за природу и тамо за промоцију новог типа дифузорских гасних турбинских мотора, тежећи смањењу емисија и загађења узрокованих њиховом употребом, док се одржава и побољшава квалитет ваздуха за све. Он је намењен да буде зеленији мотор.

Постоји бројна индустрија у којима ће брже контролисање оптерећења дифузерским моторима донети позитивну промену. Познат по томе што се користи за све од генерисања енергије до погонства, овај ОБТ дифузорски мотор са гасовинским турбинама је коначно помаже у облику нових концепта и повећање укупне перформансе. Ово укључује боље стварање млазничких мотора у дифузерској технологији која се примењује на ваздухопловну индустрију. Ефикасни реактивни мотори са продуженом даљином и укупним уносом горива значајно побољшавају ове летеће растојање и за авиокомпаније и за путнике.

На пример, у погледу електричне енергије, мишићни мотори се користе за пружање најсавременије снаге која је и високо ефикасна и изузетно чиста. О.Б.Т. дифузорски турбински мотор је високо продуктивна и оставља мање загађивача, због чега такви мотори заузимају важно место у постизању одрживије енергетске будућности наше планете.

Дифузерни турбински мотори су наша специјалност у О.Б.Т. и ми стално истражујемо нове путеве у којима се могу користити. Овде инвестирамо своје време, напоре и новац да бисмо измислили још боље системе који ће имати користи од наших клијената, наравно, чинећи животну средину сигурнијом.

Наша компанија се придржава строгих смерница за контролу квалитета како би осигурала одличне перформансе и дифузер гасне турбине сваког компоненте. Контрола квалитета се спроводи током целог процеса производње, почевши од куповине сировина до испитивања готовог производа. Такође редовно спроводимо ревизије квалитета и прилагођавања како бисмо осигурали стално побољшање квалитета производа. Наш циљ је да добијемо поверење и сарадњу наших купаца пружањем висококвалитетних производа и да постанемо лидер у индустрији.

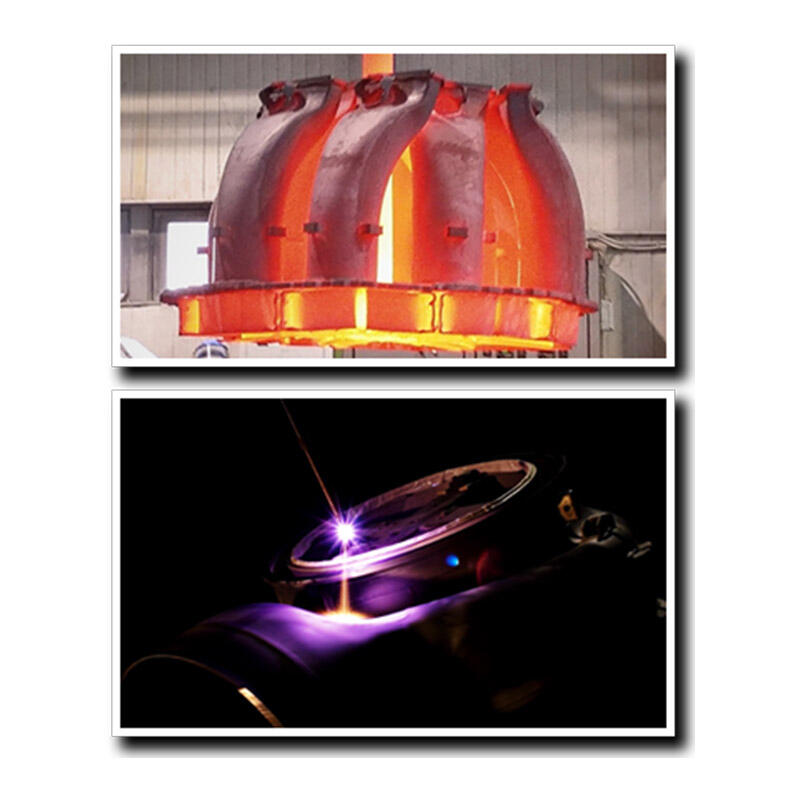

Наша компанија је у стању да производи високо прецизне и конзистентне делове турбина лежењем, ковањем и ЦНЦ обрадом. Процес лијевања нам омогућава да произведемо делове са сложеним облицима и снажном издржљивошћу, док процес ковања даје делове боље дифузор гасне турбине и дуже трајање. Технологија ЦНЦ обраде, напротив, гарантује доследност и висок квалитет сваког дела, што смањује могућност производних грешака и резултира са несавршенијим производима. Имамо високо квалификован технички тим који стално спроводи технолошке иновације и побољшање процеса како би се осигурало да наши производи остану на челу индустрије у погледу технологије. Посвећени смо испуњавању захтева наших купаца за компоненте који су високо перформансни континуираним развојем технологије.

Наша подршка клијентима је дифузорски гасни турбински мотор и укључује техничку помоћ, савете пре продаје и помоћ након продаје како би се осигурало да наши клијенти имају најбоље могуће искуство. Наш искусни тим ће прегледати потребе купаца и понудити најефикасније решење и препоруке за производ. Обезбеђујемо техничку подршку почев од избора производа до инсталације и пуштања у рад. То гарантује да наши клијенти могу да уживају у нашим производима без проблема. Имамо добро развијену услугу након продаје која нам омогућава да брзо реагујемо на захтеве и проблеме клијената и пружимо брза и навремена решења. Нама је драго што смо се удружили са нашим клијентима и пружали им квалитетне услуге.

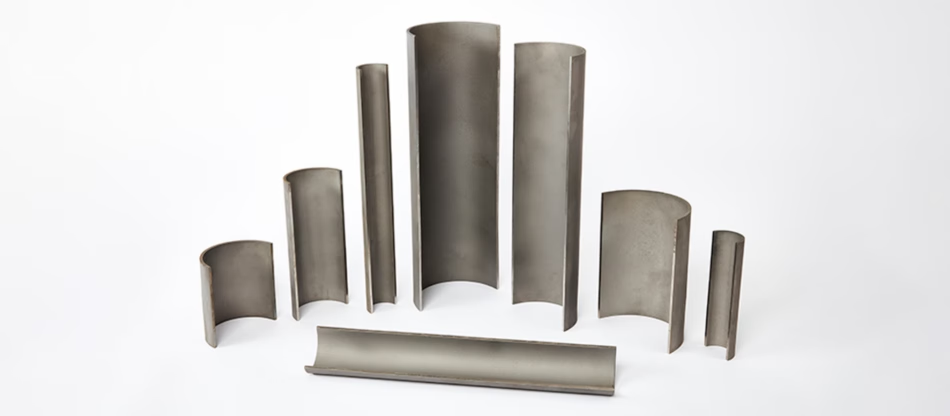

Наша компанија пружа дифузер турбина за гасне турбине, а ми смо у стању да производимо турбине делове из многих високо-температурних алуминијумских легова како би задовољили захтеве купаца. Наш флексибилан производни ток и напредна технологија за обраду и наша способност да задовољимо посебне захтеве, као што су величина и облик, као и перформансе омогућиће нам да задовољимо било коју потребу. Уско сарађујемо са купцима како бисмо у потпуности разумели њихове захтеве и сценарије апликација и пружили им стручну помоћ и предлоге. Имамо широк спектар материјала и капацитета за обраду како бисмо задовољили посебне захтеве различитих индустрија и апликација. Наши клијенти могу побољшати своју конкурентност на тржишту нудећи прилагођене услуге које оптимизују перформансе и смањују трошкове.