When you think about airplanes, they likely conjure images of soaring high up in the vast blue sky. Ever wondered what exactly allows these machines to glide in such an efficient and quick manner? The reason can be attributed to the power plants that propel these tanks - their monstrous gas turbine engines! One of the most important thing that contributes to this workability is known as gas turbine vane. They are such small pieces but carry so much weight when it comes to the flight of an airplane.

Gas turbine vanes are tiny pieces of metal contained within the gas engine. Although they are tiny, their form factor and placement have an appearance of essentiality for the engine to operate as needs. Vanes to direct and control the flow of hot gases produced when fuel burned in a gas turbine. The hot gas is then pushed out toward the blades of the engine to generate thrust that enables forward movement of an aircraft. If it werent for these vanes, the engine would not operate as effectively and planes couldnt fly so fast (or in some cases at all).

The other is manufacturing the gas turbine vanes, a complex and highly skilled process that has seen advancement through use of superior technologies. Designers first create through computer programs the optimal shape and size of the vanes. This makes these programs very useful with the ability to simulate engine performance under numerous scenarios and conditions. This enables engineers to check out various layouts before they develop anything literally.

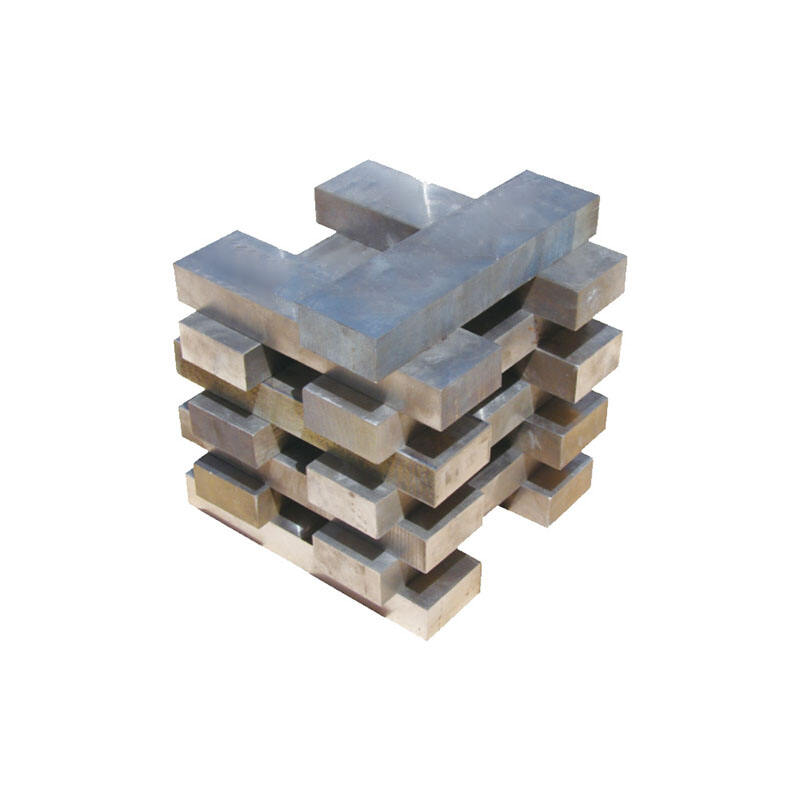

As you can see, after design is done and approved the next step in creating of a vane shape is creation of mold for it. The shape of this mold is specially made to suit the design for vane. It is then placed in a machine that heats up the mixture of metals, which are called metal alloy and poured into it. Now, when the alloy is warmed up it can be poured into this mold. Once the metal has cooled and solidified, it is removed from the mould (left) and inserted into a gas turbine engine (right). After making this milk it was clear to me that delicately precise work is required for the whole process.

Through the decades, there have been a number of cool new ideas for improving gas turbine vanes. New technologies improved the efficiency of a gas turbine engine courtesy of modern scientist and engineers. This will involve a novel approach to dealing with the vanes, including adding unique ceramic coating. This ceramic coating has an important function; that is to keep the heat of the vanes in operation be them cold for 1 day or hot like a hennessey supercharger and stay alive, so it can last longer time working.

Using 3D printing to manufacture gas turbine vanes is another revolutionary approach. This advanced technology has enabled manufactures to form more complex shaped blades that were previously impossible with traditional methods. 3D printing enables designers to test various designs and shapes that prove most effective in increasing engine performance strides, leading torque figures and drive efficiency.

Advanced tech in the world of gas turbine vanes will only get better as time goes on. Engineers love thinking up fresh ways to make gas turbine engines lighter and more compact. With reduced weight, we are likely to lower carbon emissions and reduce fuel consumption rates as well This benefit means less of whatever your engine usage is (fuel or diesel), which in addition saves not only money but also the environment.

Our complete customer service package includes technical assistance pre-sales advice and after-sales assistance to ensure that our customers receive the best experience possible At the time of pre-sales our team of experts will be able to understand the needs of the customer in detail and provide the most appropriate product suggestions and solutions We offer technical assistance from the selection of products through installing and commissioning This guarantees that our customers are gas turbine vane to use our products without any issues We have a well-developed after-sales system that allows us to respond quickly to customer concerns and issues and provide efficient and prompt solutions We aim to build long-term relationships with our clients and earn their trust and satisfaction by providing quality service

We are able to create turbine components with high accuracy and consistency using CNC casting, machining and forging processes. Casting allows us create parts with gas turbine vane, strong and durability. Forging offers parts more durable and superior mechanical property. CNC machining, on the contrary is extremely precise and consistency for each part. This eliminates mistakes and poor quality products. Our experienced technical team is continuously researching technological advances and process optimizations in order to keep our products at the leading edge of industry technology. We're committed to meeting the demands of our customers for high-performance turbine components by the continuous advancement of technology.

Our company offers specific services that is able to manufacture turbine parts from various high-temperature alloys in order to satisfy the demands of customers. Our flexible production flow as well as our state-of-the-art process technology and our ability to satisfy particular requirements, like size and shape, as well as performance will allow us to meet every requirement. We are in constant contact with our customers in order to fully understand their needs specific to them and the application scenarios, and provide them with expert technical guidance and solutions. We have a rich selection of processing and materials that can meet the gas turbine vane of various sectors and application. Through customized services, we assist our customers in optimizing their product performance and cost, and improve market competitiveness.

Our company follows strict gas turbine vane standards in order to ensure excellent performance and dependability of each component. Quality control is conducted throughout the entire production process beginning with the purchase of raw materials through the test of the finished product. To ensure that the quality of our products is continuously improved, we perform regular audits and improvements. We strive to earn the trust of our clients and their long-term partnership by providing products of high-quality.