Single crystal blade technology is a type of intriguing blades that has been cast from one huge slab. Photograph:Stephanie Pappas]Imagine it a bit like Superman's crystal Fortress of Solitude! This is also for the simple reason that the blades are made from a single piece of metal, which eliminates weaker areas. This makes them more stable, robust. So, single crystal blades can take a massive amount of pressure and hotness — the sort of basic details an aircraft engine looking to go as fast as possible might dig.

While single crystal blades are not new, and have been used in aircraft engines for decades. Now, with the development of new technologies and engineering capabilities by experts, larger and stronger single crystal blades can be produced. In other words, it can fly faster and higher for longer. The benefit of the single crystal blades is also they are more robust and sturdy, leading to longevity that can enable their use in many flights before discarding them.

An example of a company employing this phenomenal single crystal blade technology—collectively known as General Electric, or GE. A Few Great Years GE has been a leader in airplane engine technology. Gone with the old where 3D printed blade, a single crystal technology from this topic. In other words, something printed with a special kind of printer that can produce shapes as complex as an artist wanting to create art. GE's 3D-printed blades are better than previous designs, which provides a huge boost for aviation.

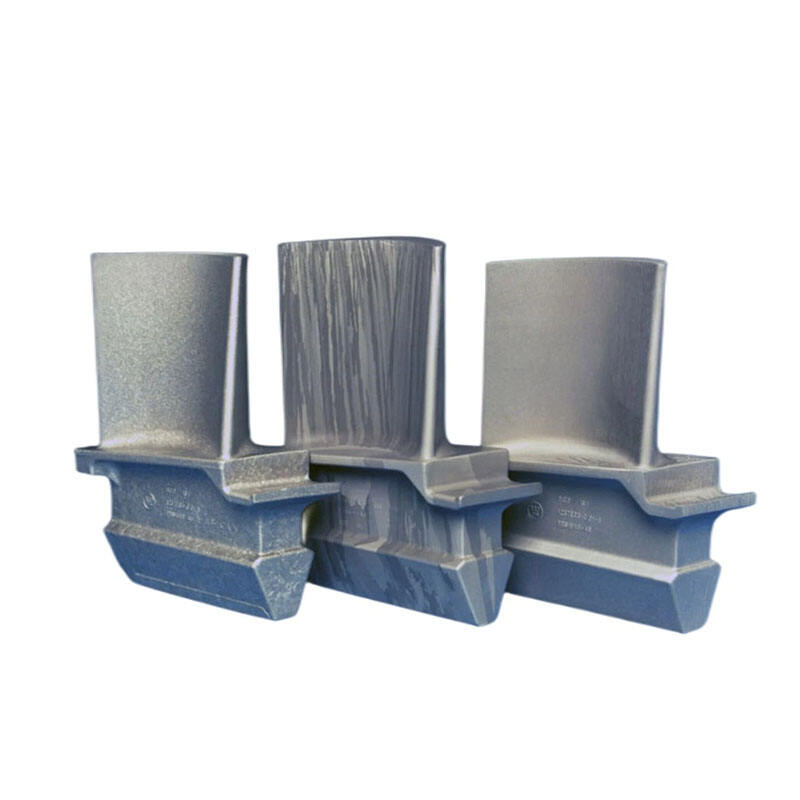

And A new question arises, how they make these awesome single crystal blades. Directional solidification for producing an individual crystal blade. It is almost like making popsicles. Instead of going for that juice, they chose hot metal cooling down. The metal cools and a crystal structure forms, creating a single-crystal blade.

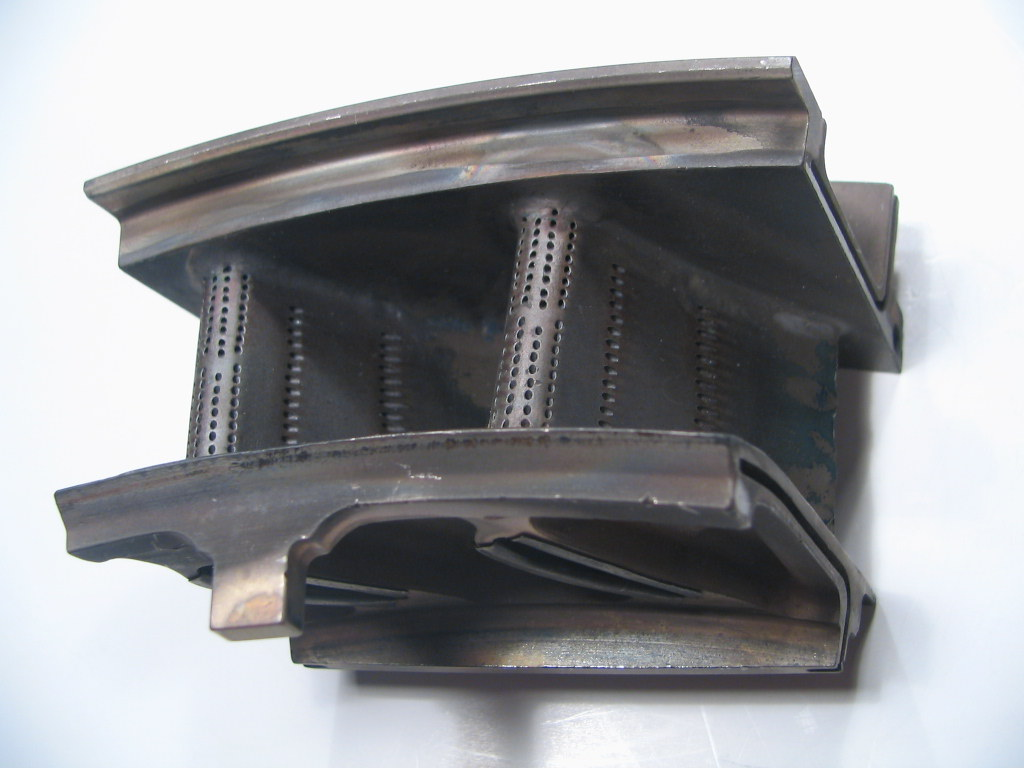

The gas turbine blades are what make the plane move, they go inside of the airplane engine. It does this through forcing hot gases produced when burning fuel. These hot gases bounce against the turbine blades causing them to rotate. This spinning is what drives the engine and provides power to lift the airplane off into flight.

A key advantage that single crystal blade alloys have is the ability to be used in very high temperature applications. It is extremely important for the engines used in planes as they generate everything lot of heat when working. The particular metal alloys used in turbocharger construction are intended to withstand these temperatures, and many mechanisms limit thermal stress on the engine.

These are also high strength alloys and are fixed so that they withstand heath. They are high-strength which is crucial for airplane engines performing at peak capacity. In addition, these alloys are lightweight and do not contribute much to the weight of an airplane. This allows the plane to travel faster and more efficiently, benefitting everyone on board!

Our company offers customized services, and can produce turbine components from an array of single crystal blade metals to meet the needs of customers. Our flexible production flow, advanced process technology, and our capacity to meet particular requirements, like size shape, performance, or shape can allow us to meet any requirement. We work closely with our clients to comprehend their needs specific to them and the application scenarios and provide professional advice and solutions. Our diverse selection of materials, processing capabilities and application-specific requirements allow us to meet the needs of a variety of industries and. With customized services, we help our customers optimize product performance and cost as well as increase market competitiveness.

We provide a single crystal blade, including pre-sales consultation as well as technical support and after-sales services to ensure that our customers enjoy the most enjoyable experience. Our expert team will assess the needs of customers and offer appropriate products and solutions. Concerning technical assistance, we provide all the guidance needed from choosing a product to installation and commissioning to ensure that customers can use our products without difficulty. In terms of after-sales service we have designed a flawless service system to react quickly to customer concerns as well as needs, and provide quick and effective solutions. Our goal is to develop long-term relationships, and gain customers trust and satisfaction through superior customer service.

We adhere to the strictest guidelines for quality control to ensure the single crystal blade and reliability each component. Every step of the production process is monitored for quality starting from the purchase of raw materials all the way to the final test of the product. To ensure that the quality of our products are continuously improved, we conduct regular audits and improvement. We want to win the trust of our customers and their long-term cooperation by providing high-quality products.

Our company is able to fabricate highly precise and stable turbine components through casting, forging and CNC machine processes. The casting process permits us to single crystal blade with complex shapes and high durability, while the forging process gives the parts better mechanical properties and longer lasting. CNC cutting-edge technology, on contrary, provides the highest precision and accuracy of every part, which reduces the chance of manufacturing errors and resulting in substandard products. We have an experienced technical team who continuously carry out technological innovation and process improvement to make sure that our products are always at the top of the industry in terms of technology. Our commitment is to meet the needs of our customers for components that are high-performance by developing technology continually.